Integrative aerobic particle sludge membrane bioreactor sewage treatment method

An aerobic granular sludge and membrane bioreactor technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve rare problems, achieve accumulation alleviation and stable operation , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

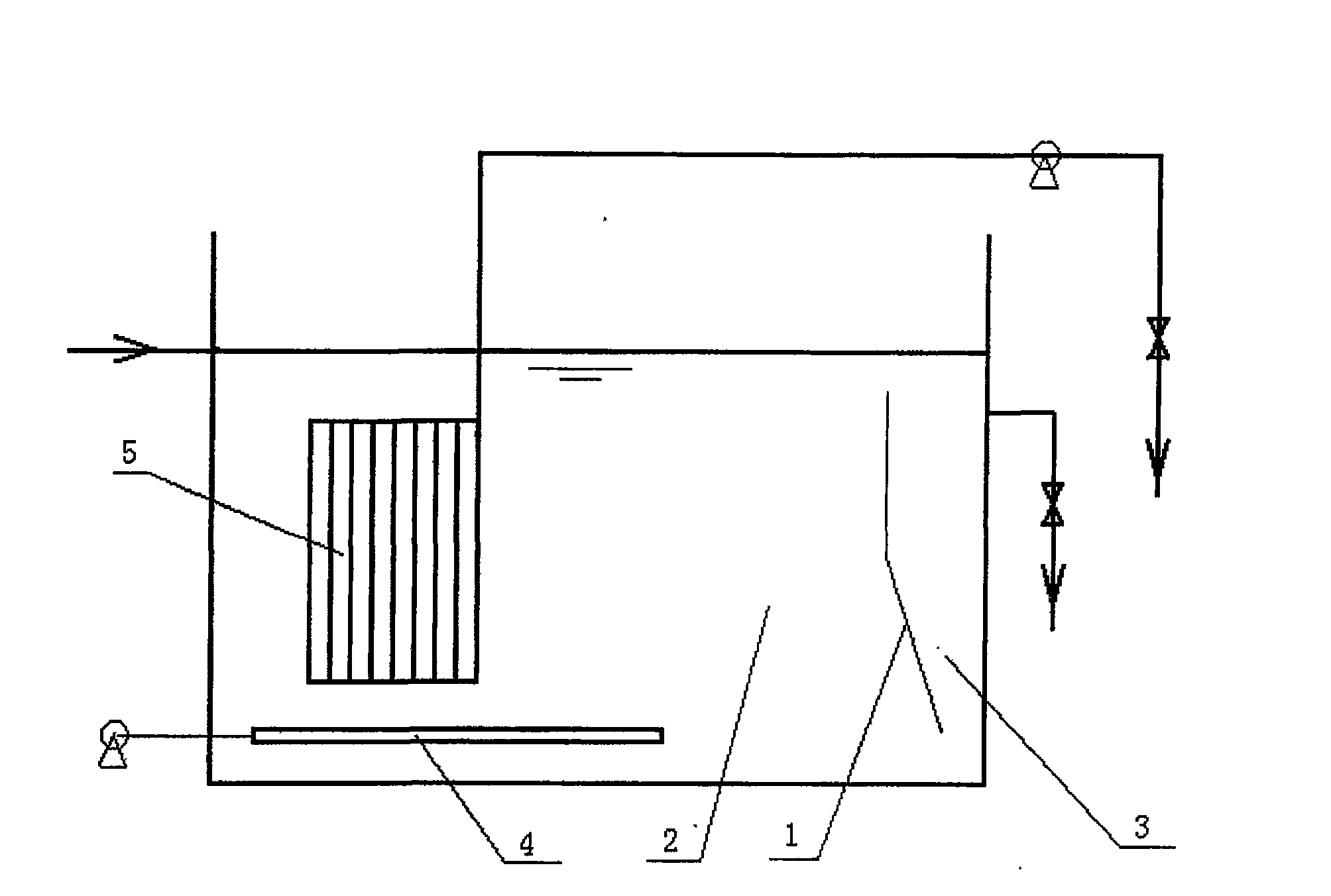

Image

Examples

Embodiment 1

[0029] The effective volume of the reactor is 10 liters, the volume of the precipitation zone is 1 liter, the temperature is controlled at 20-25°C, the MLSS is controlled at 5000-7000 mg / L, and the sludge age is 40 days. Using artificial water distribution with sodium acetate as the organic matrix, the concentration in terms of COD is 200-400mg / L, ammonia nitrogen is 30-40mg / L, and total nitrogen is 35-50mg / L. The particle size of inoculated aerobic granular sludge is 800-1800 microns. The water outlet time of the membrane is 7 to 14 minutes, and the precipitation water outlet time is 3 to 6 minutes, alternately. The reactor runs continuously for 60 days without any hydraulic and chemical cleaning of the membrane components. The organic matter, ammonia nitrogen and total nitrogen in membrane effluent water are 5-10mg / L, 1-3mg / L, 2-5mg / L respectively; L, 5~10mg / L. And the aerobic granular sludge with a sludge particle size greater than 400 microns in the reactor accounts for...

Embodiment 2

[0031] The effective volume of the reactor is 8 liters, the temperature is controlled at 20-25°C, the MLSS is controlled at 4000-6000 mg / L, and the sludge age is 50 days. Using the effluent from the primary sedimentation tank of a city sewage treatment plant, the COD concentration is 150-200mg / L, the ammonia nitrogen is 30-40mg / L, and the total nitrogen is 40-50mg / L. The particle size of inoculated aerobic granular sludge is 800-1800 microns. The water outlet time of the membrane is 8 to 16 minutes, and the precipitation water outlet time is 2 to 4 minutes, alternately. The reactor has been running continuously for 80 days without any hydraulic and chemical cleaning of the membrane components. The organic matter, ammonia nitrogen and total nitrogen in membrane effluent water are 5-10mg / L, 1-3mg / L, 2-5mg / L respectively; L, 5~10mg / L. And the aerobic granular sludge with a sludge particle size greater than 400 microns in the reactor accounts for more than 85% of the total slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com