Method for doping Sb for growing Zn1-x MgxO crystal film

A zn1-xmgxo, crystal technology, applied in the field of growth of p-type Zn1-xMgxO crystal thin films, can solve problems such as influence, and achieve the effect of simple method and high concentration doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

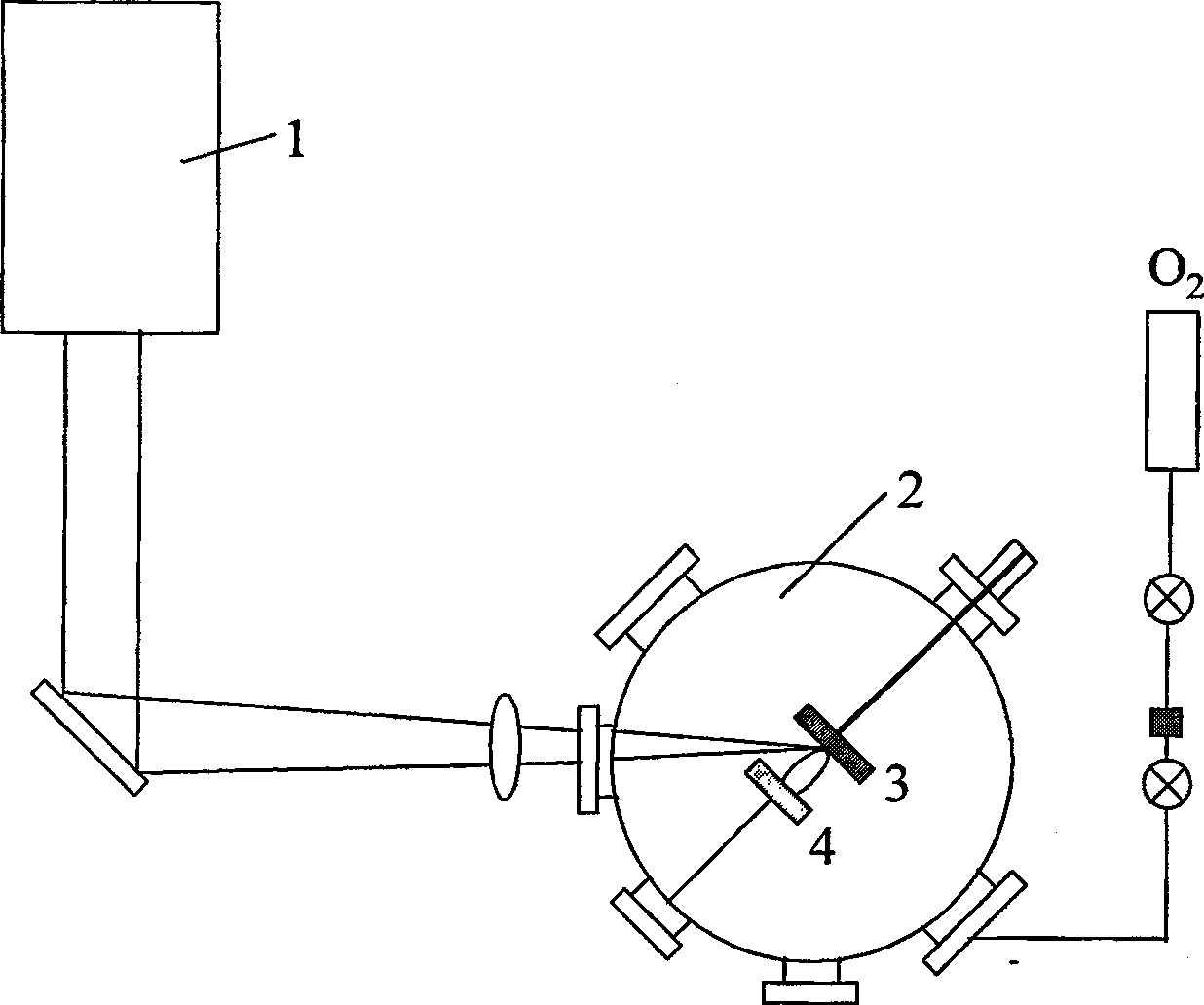

[0017] Combine the following figure 1 , the present invention will be further illustrated by examples.

[0018] Sb-doped growth of p-type Zn 1-x Mg x The method for O crystal thin film, step is as follows:

[0019] 1) Preparation of ceramic target Weigh ZnO, MgO and Sb with a purity of 99.99% 2 o 3 Powder, wherein the molar percentage of Mg is 5%, and the molar percentage of Sb is 2.96%. The weighed ZnO, MgO and Sb 2 o 3 The powder was poured into a ball mill jar with agate balls, and milled on a ball mill for 18 hours, in order to combine ZnO, MgO and Sb 2 o 3 The powder is well mixed and finely grained to some extent. Then the raw materials are separated and dried, added with a binder for grinding, and pressed into shape. Put the formed green body into the sintering furnace, discharge elements at low temperature (400°C) to volatilize the binder, and then heat up to 1200°C for 2 hours to obtain Sb-doped Zn 0.95 Mg 0.05 O ceramic target.

[0020] 2) The preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com