Dendritic silver selenide nano crystal thin film material and preparation method

A thin film material, silver selenide technology, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology and other directions, can solve the problems of harsh conditions, high solvent toxicity, complex process, etc., to achieve convenient operation, fast reaction, avoidance of Product impure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

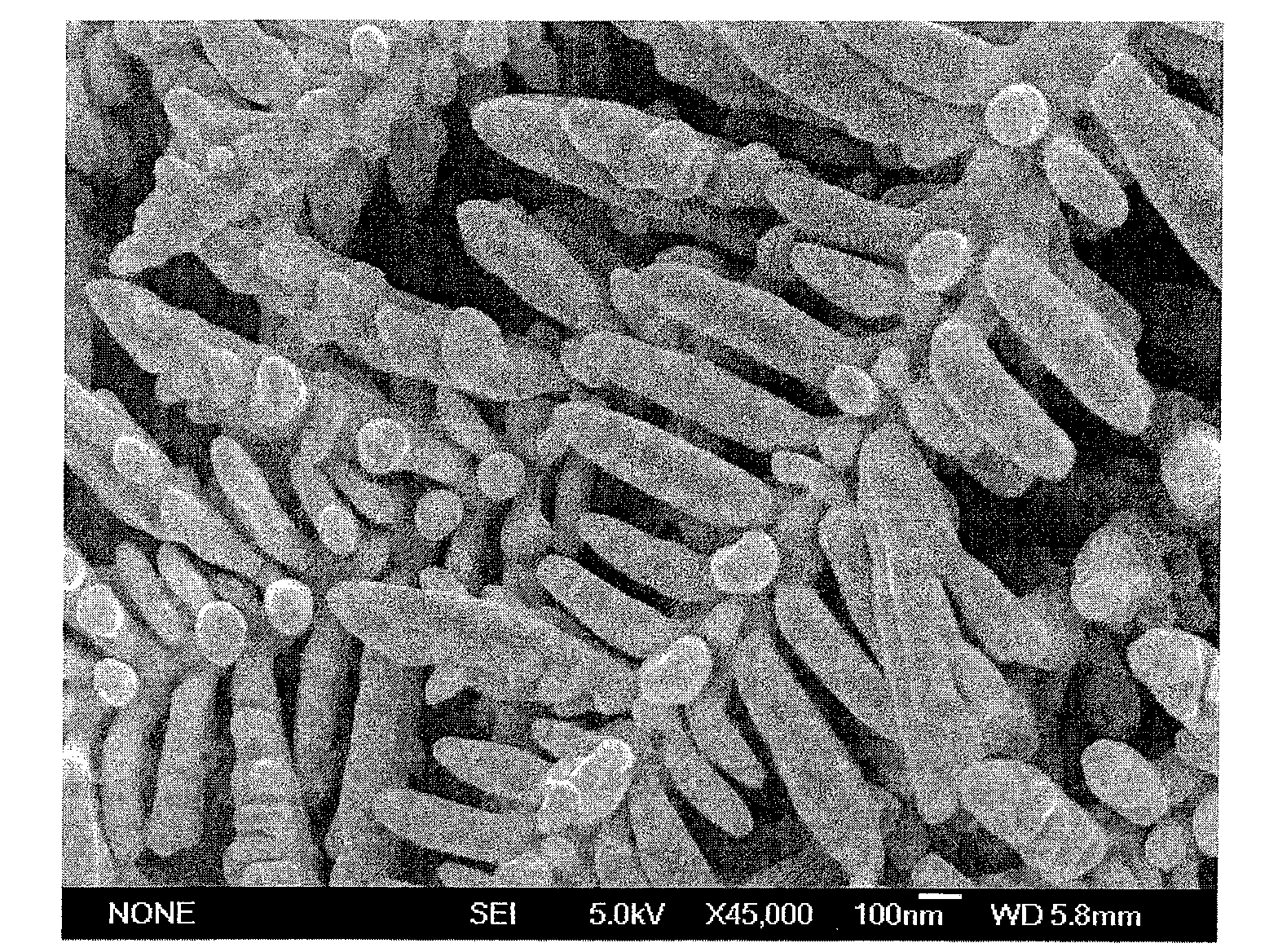

Embodiment 1

[0021] (1) Preparation: Put the analytically pure metallic silver foil into a beaker filled with deionized water, clean it with an ultrasonic cleaner for 0.5 hours, and then soak it in absolute ethanol for use. Wash the polytetrafluoroethylene container successively with tap water, distilled water, and absolute ethanol, and dry it for use.

[0022] (2) Reaction steps: put the processed metal silver foil into the polytetrafluoroethylene container, add methanol solvent to the height of 80% of the container and add selenium powder at the same time, the concentration of selenium powder is 0.0007 g / ml, polytetrafluoroethylene The vinyl fluoride container was placed in a stainless steel jacket and placed in a muffle furnace with a temperature-programmed function. The temperature increase rate was 2°C / min, and the temperature was raised to 160°C for 12 hours.

[0023] (3) Post-processing: After the reaction, turn off the power supply of the muffle furnace and let it cool down to room...

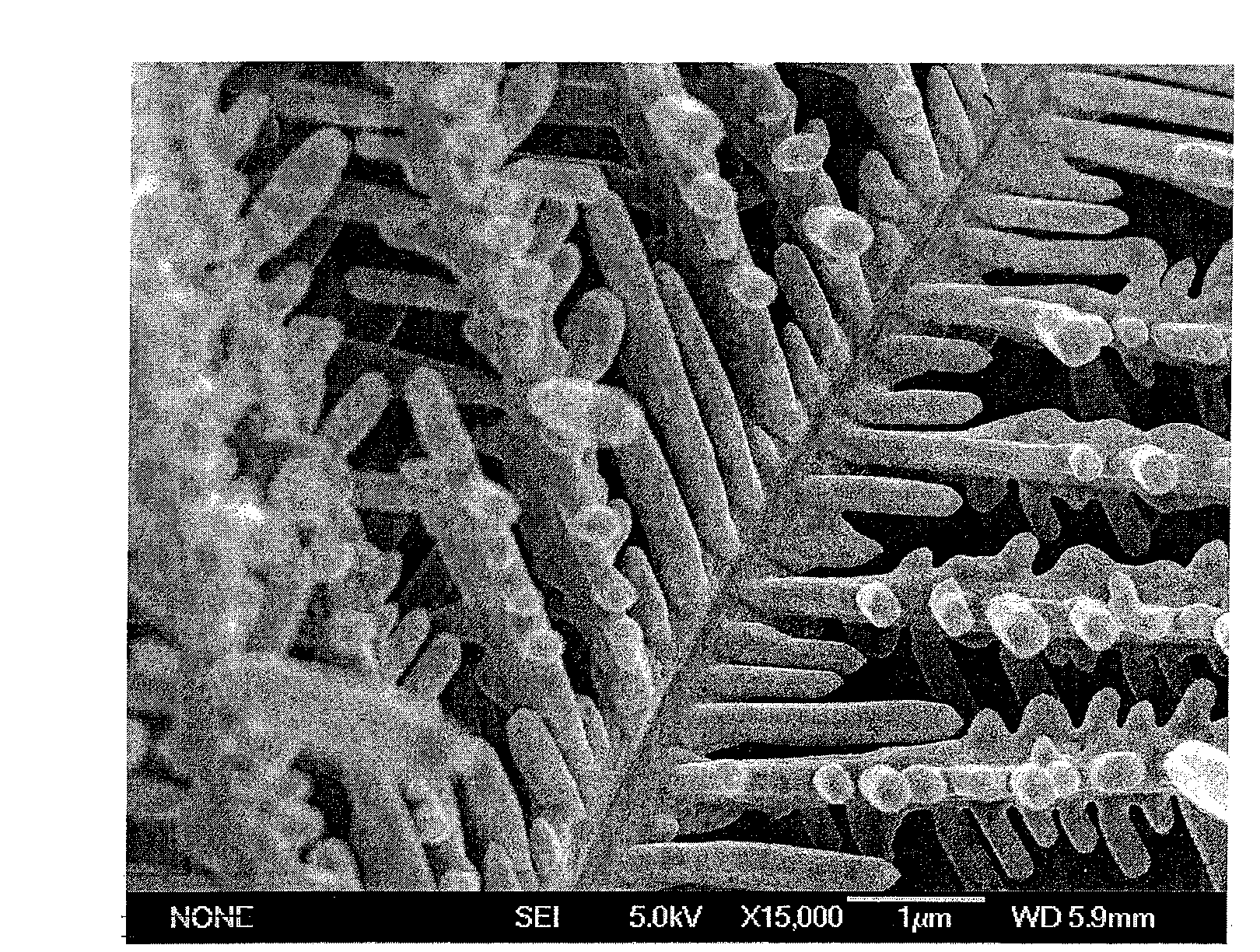

Embodiment 2

[0025] (1) preparatory work: with embodiment 1

[0026] (2) Reaction steps: put the processed metal silver foil into the polytetrafluoroethylene container, add dodecyl alcohol solvent to the height of 80% of the container and add selenium powder simultaneously, the concentration of selenium powder is 0.0014 g / ml, and The polytetrafluoroethylene container was placed in a stainless steel jacket and placed in a muffle furnace with a temperature-programmed function, and the temperature was raised to 180°C, and the reaction was carried out for 6 hours at a heating rate of 10°C / min.

[0027] (3) Post-processing: After the reaction, turn off the power supply of the muffle furnace and let it cool down to room temperature naturally. Wash the product twice with absolute ethanol, put it into a vacuum drying oven and dry it at 50°C for 4 hours to obtain a silver selenide thin film sample, then carefully transfer it into a sample bottle, and store it in a dark and dry environment. The col...

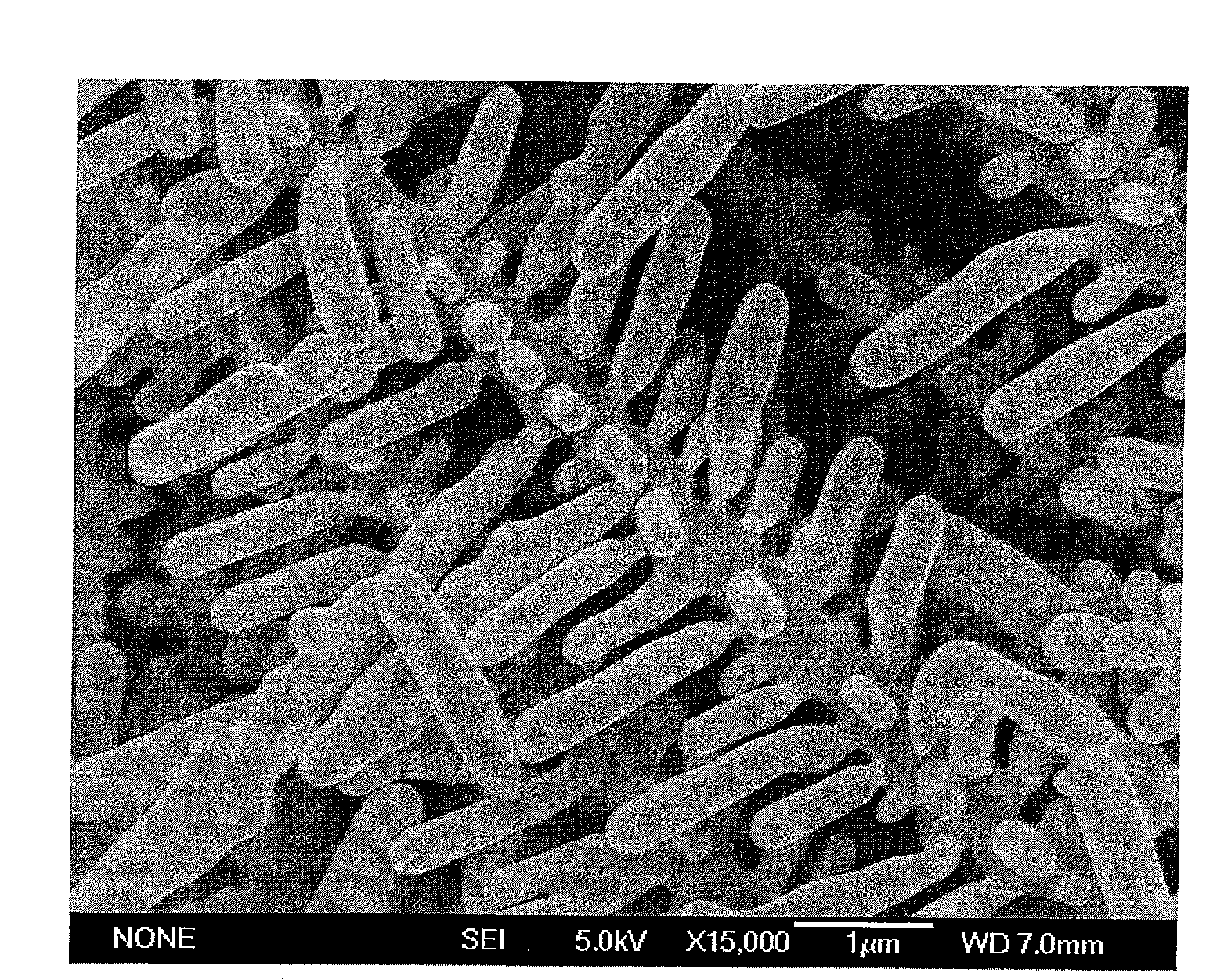

Embodiment 3

[0029] (1) Preparatory work: the freshly prepared semiconductor silicon wafer coated with a layer of nano-silver film on the surface (electrochemical deposition) is used as a reaction substrate, and put into a vacuum drying oven for standby. Wash the polytetrafluoroethylene container successively with tap water, distilled water, and absolute ethanol, and dry it for use.

[0030] (2) Reaction steps: the semiconductor silicon chip that the surface is coated with one deck nanometer silver film is put into polytetrafluoroethylene container, adds ethanol solvent to the height of 80% of container and adds selenium powder simultaneously, and selenium powder concentration is 0.0007 gram / Put the polytetrafluoroethylene container into a stainless steel jacket and place it in a bench-top drying oven with a temperature-programmed function, raise the temperature to 140°C and react for 3 hours, with a heating rate of 5°C / min.

[0031] (3) Post-treatment: After the reaction, turn off the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com