Composite mould with internal mini crack on liner for vibration forming building block/ ground brick

A technology of vibration molding and composite molds, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve the problems of wear, high mold cost, deformation of mold lining, etc., and achieve the effect of improving product quality, increasing mold life, and reducing mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

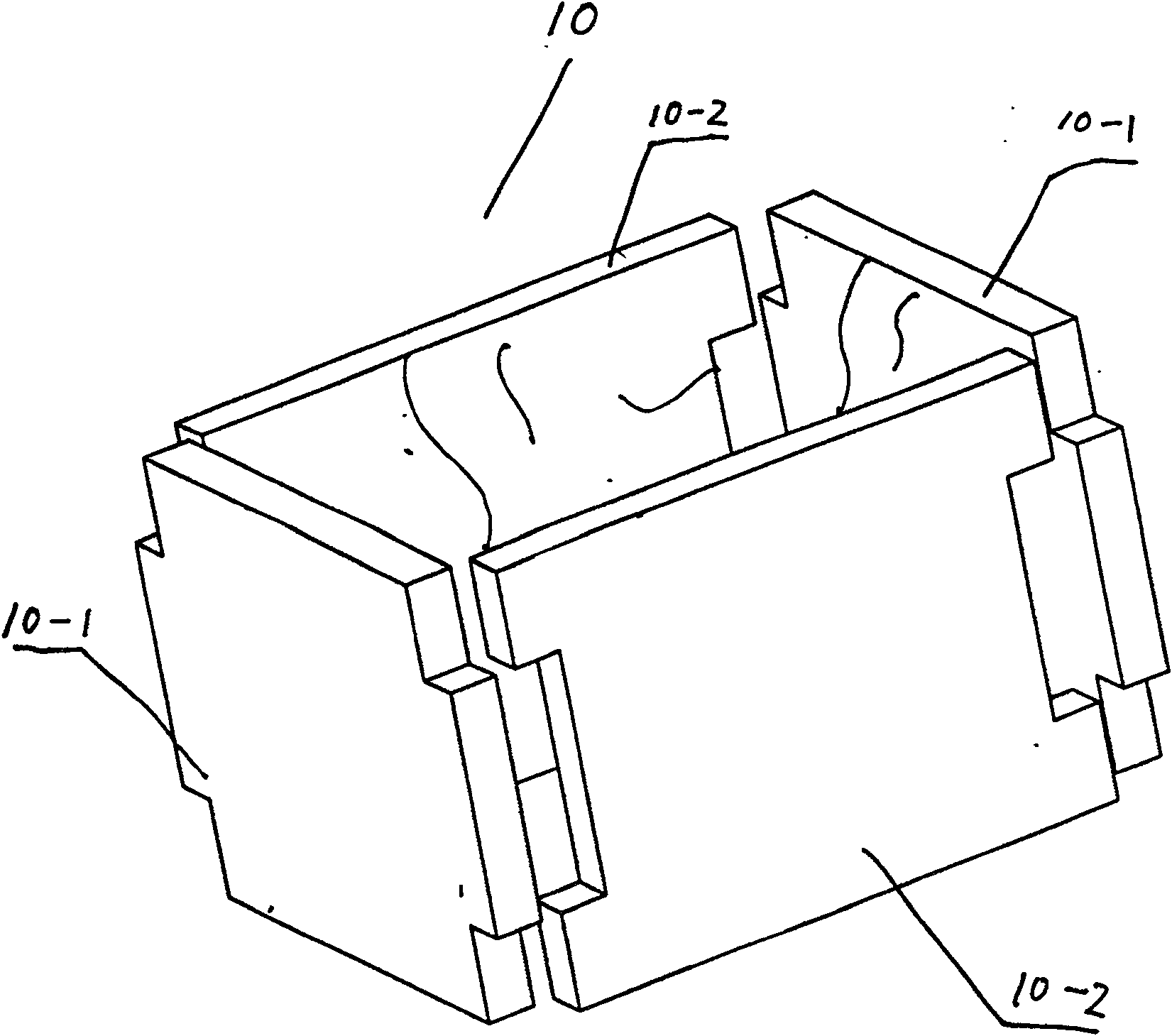

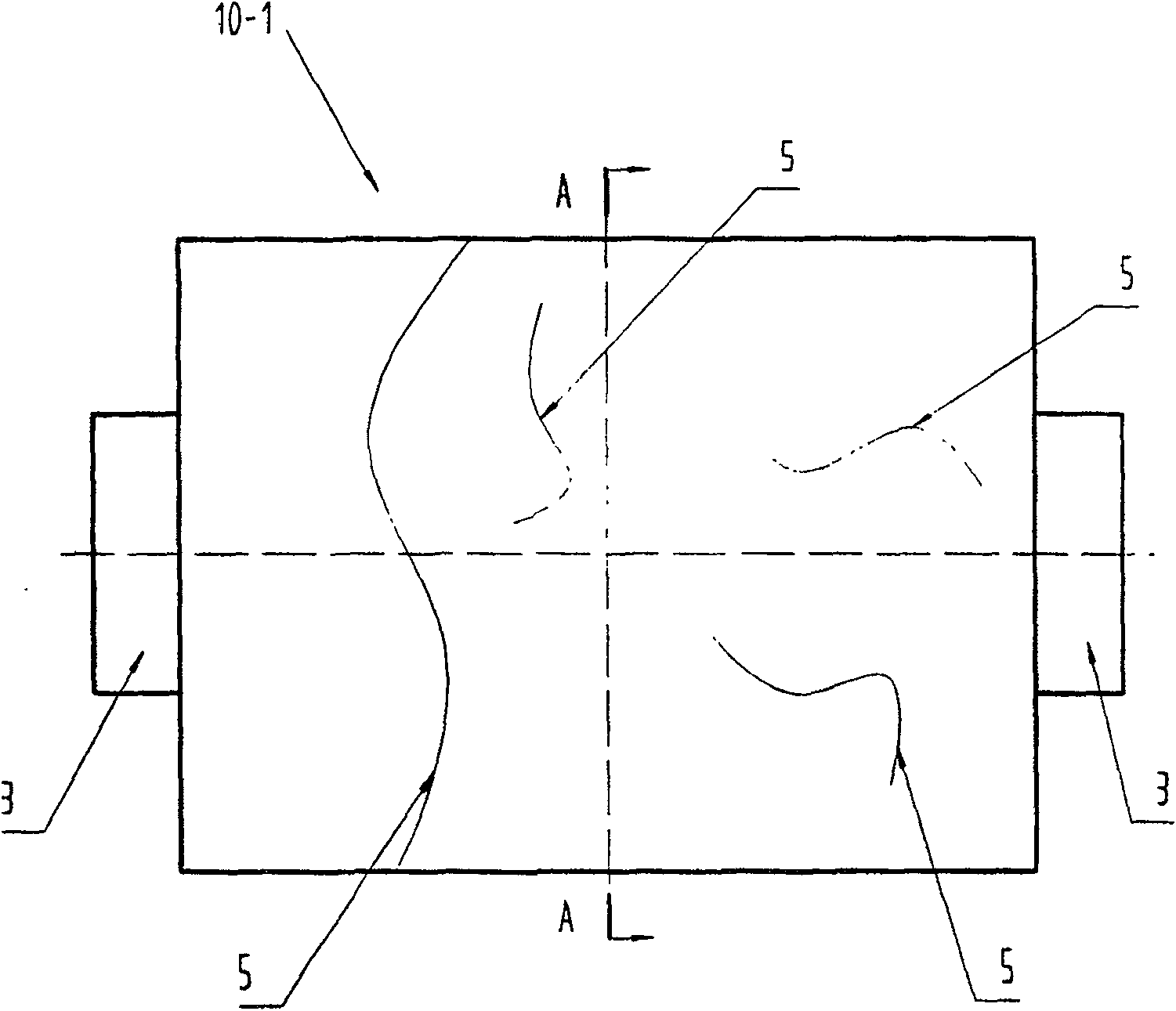

[0052] Embodiment 1: the manufacture of a composite mold with microcracks in the inner cavity of the vibration-formed floor tiles of 300 mm × 300 mm × 60 mm

[0053] 1. Manufacture of composite liner 10-1:

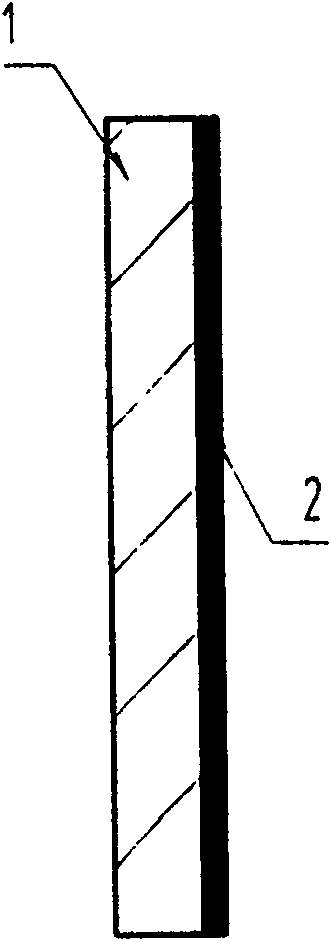

[0054] 1. By milling method will image 3 The low-carbon steel bottom plate 1 of the lining plate 10-1 made of metal materials is processed to 322mm×71mm×10mm;

[0055] 2. Use tungsten argon arc welding 500 ampere DC surfacing welding machine, the working current is determined to be 280 amperes, and the HS101 surfacing welding wire with a diameter of 6 mm and a C content of 2.5%-3.3% and a Cr content of 25%-31% is selected. , the inner lining layer 2 formed by overlaying CrC alloy welding layer on the inner side of the bottom plate 1, the size is 280mm×50mm, the thickness of the weld bead is ≥5mm; the hardness HRC of the obtained metal inner lining layer is 50-70, and the surface of the metal inner lining layer Form micro-cracks 5 in the up-down direction, left-right dir...

Embodiment 2

[0067] Embodiment 2: the manufacture of a composite mold with microcracks in the inner cavity of the vibration-formed floor tile of 100mm × 200mm × 60mm

[0068] 1. Manufacture of composite liner 10-1:

[0069] 1. By planing the method will figure 2 The low-carbon steel bottom plate 1 of the lining plate 10-1 made of metal materials is processed to 122mm×71mm×10mm;

[0070] 2. A tungsten argon arc welding 500 ampere DC surfacing welding machine is used, the working current is determined to be 280 amperes, and a 6 mm diameter HS103 surfacing welding wire with a C content of 3.0%-4.0% and a Cr content of 25%-32% is selected. The inner lining layer 2 formed by surfacing welding CrC alloy welding layer on the inner side of the bottom plate 1, the thickness of the weld bead is ≥ 5mm; Micro-cracks 5 in irregular directions. The width of micro-cracks 5 is in the range of 0.1 mm to 0.5 mm. In the lining, the number of micro-cracks is at least one per square centimeter.

[0071] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com