Ultraprecise and low-damage method for polishing large size diamond wafer and device thereof

A polishing device and diamond technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., to achieve the effect of solving poor polishing surface quality, low processing cost, and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

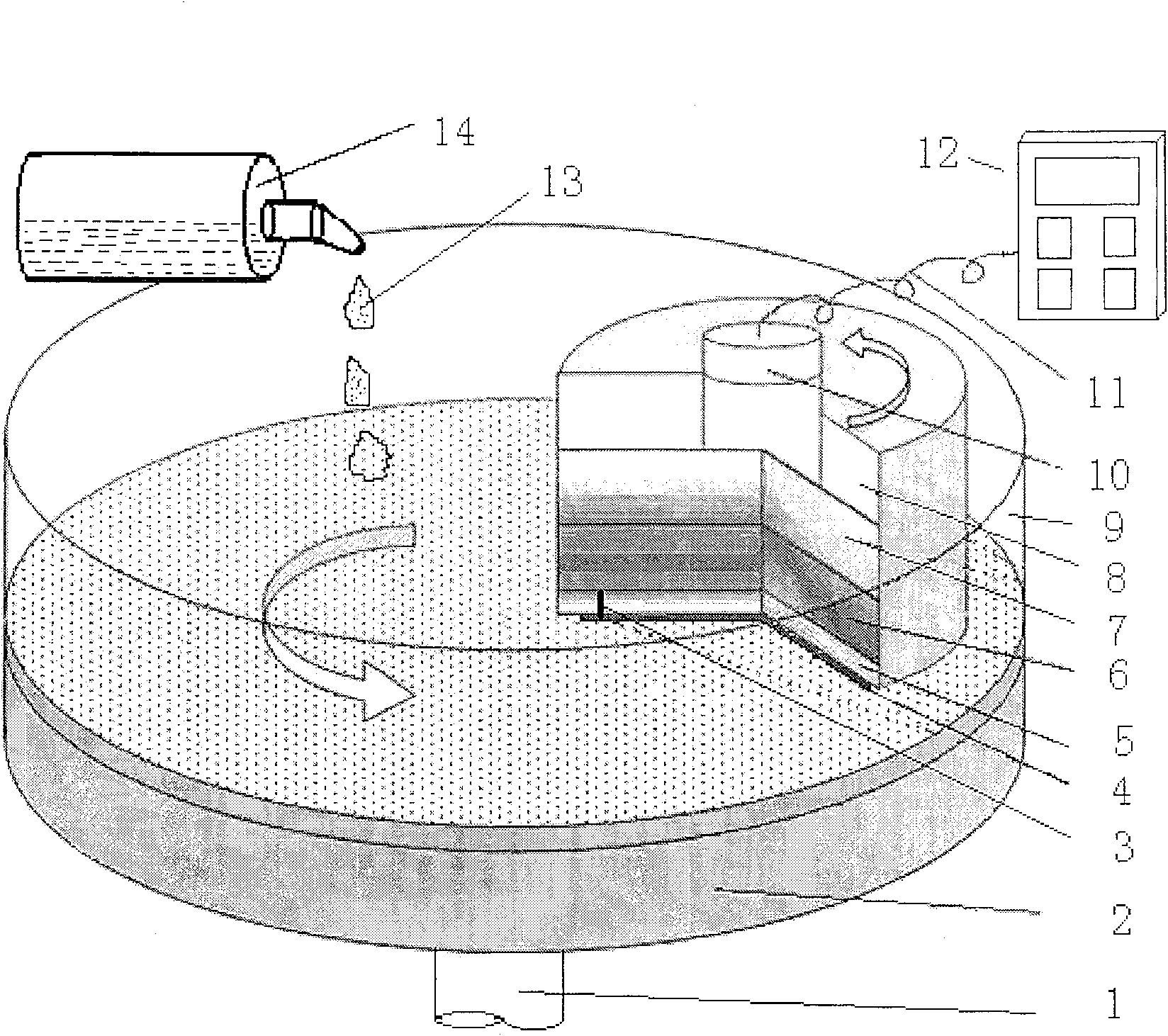

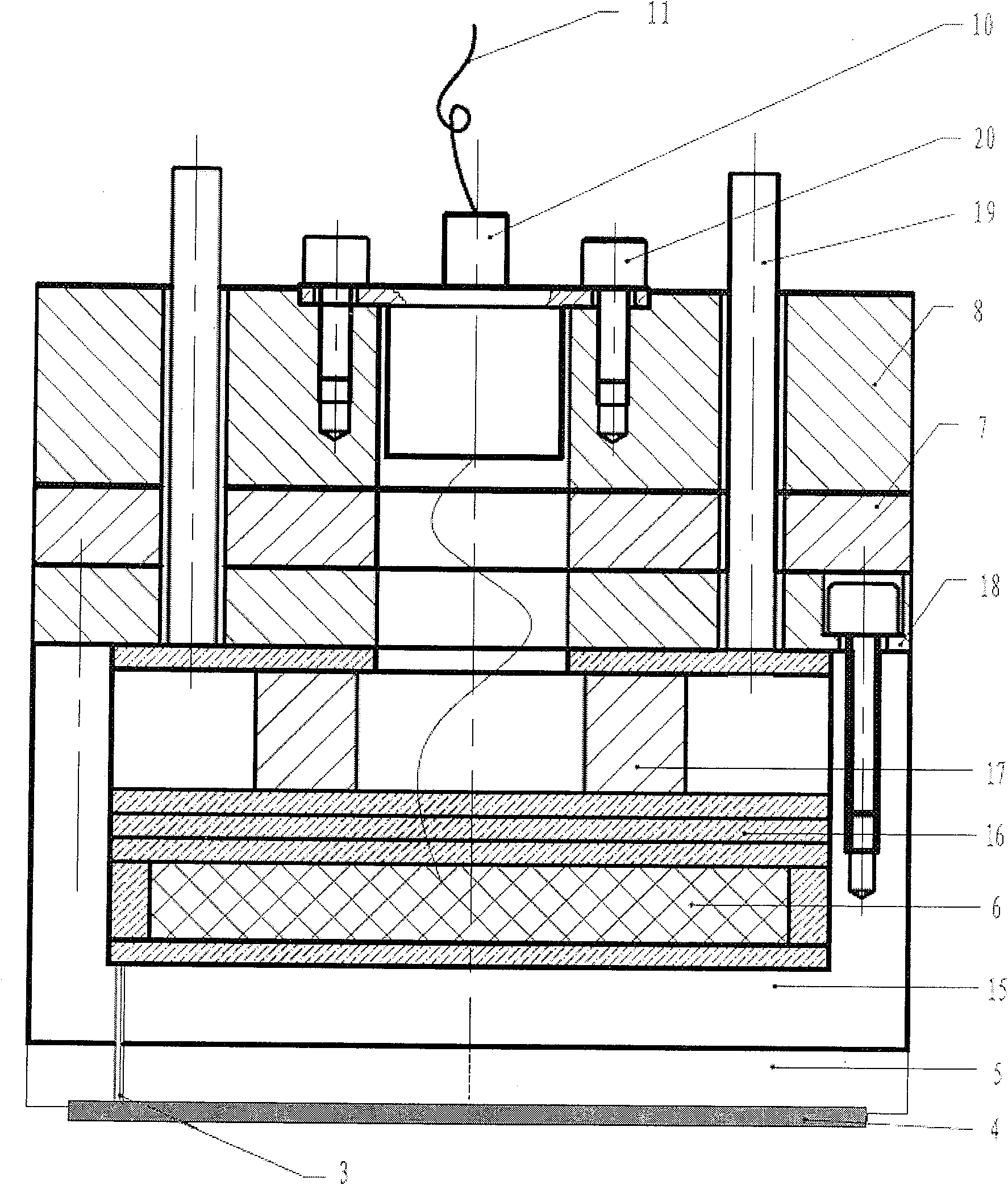

[0014] as attached figure 1 As shown, the polishing device of the present invention includes a polishing machine body, a polishing disc 2, a polishing head, a dripper 14, a collector ring 10, a polishing machine cover 9, and an external electric heating temperature regulating device 12 and the like. The polishing machine cover 9 is installed on the polishing disc 2 and rotates with the polishing machine, and is mainly used to prevent the splashing of the corrosive polishing liquid. The polishing disc 2 adopts cast iron discs, glass discs, ceramic discs and polishing pads with good corrosion resistance and wear resistance. The polishing head is composed of a glass plate 5, a counterweight A, and a built-in electric heating plate 6 and a thermocouple 3. The bottom of the polishing head adopts a glass disc 5 with excellent corrosion resistance, and the diamond wafer is pasted on the surface of the glass disc. In order to make the diamond wafer stick firmly, first process a shal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com