Joist type cable arch bridge structure and its construction method

A cable arch bridge and truss-type technology, which is applied in the field of truss-type cable-arch bridge structure and construction, can solve the problem that construction units are difficult to complete the construction task of large-span concrete-filled steel pipe arch bridges, lack of sites for prefabrication and lifting of long components, and heavy weight of prefabricated components, etc. problem, to achieve the effect of shortening the cost, reducing construction equipment and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

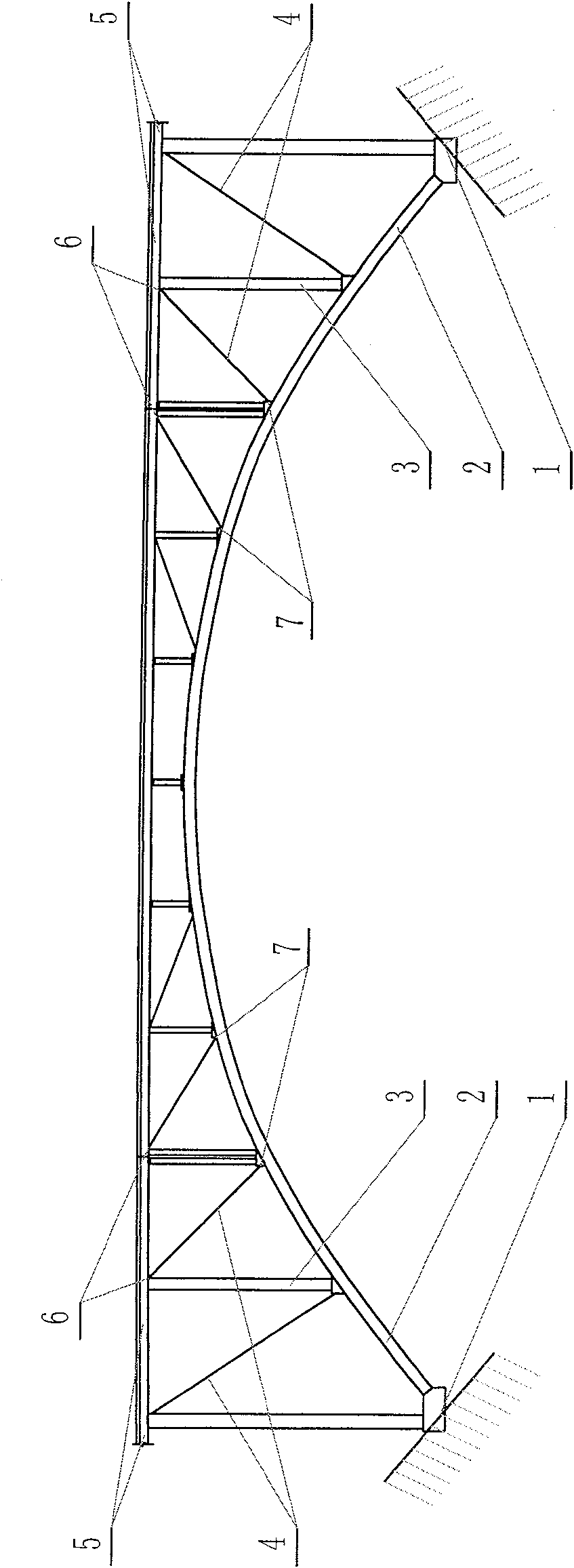

[0042] Example 1: The Maojing Bridge in Luodian County, Longtan Hydropower Station, Guizhou is designed as a continuous rigid structure of 76+128+76=280m, with a pier height of 100m. Due to the water storage in advance of the power station, the pier foundation was submerged and the construction was forced to stop. As a result, the span had to be enlarged and the pier moved to the submerged line, and the cost would increase to 35 million yuan. If the single-span "240m three steel pipe truss structure concrete truss cable arch bridge" is used instead according to local conditions, such as Figure 6 As shown, the high pier and underwater foundation construction can be canceled, saving nearly 10 million yuan in cost.

[0043] A concrete truss cable arch bridge with three steel pipe truss structures as the main arch ring Figure 1-6 As shown: the lower chord main arch ring is composed of three arched steel pipes 8 filled with concrete to form an isosceles triangular cross-section s...

Embodiment 2

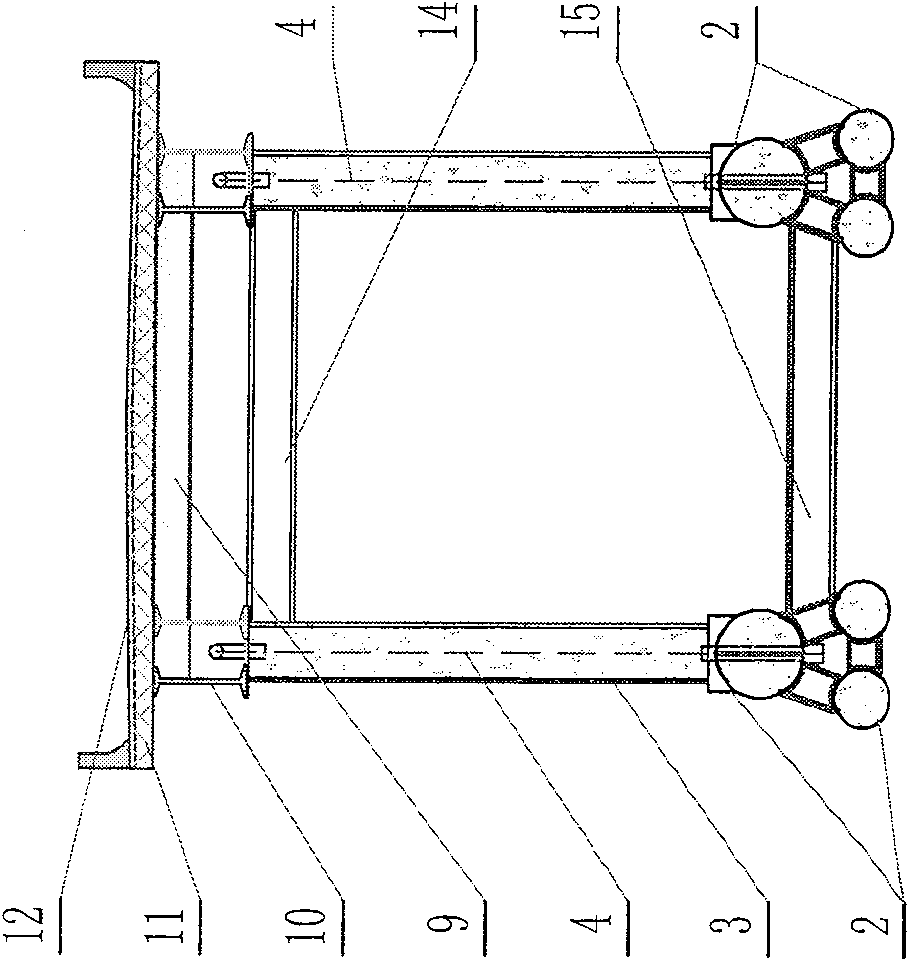

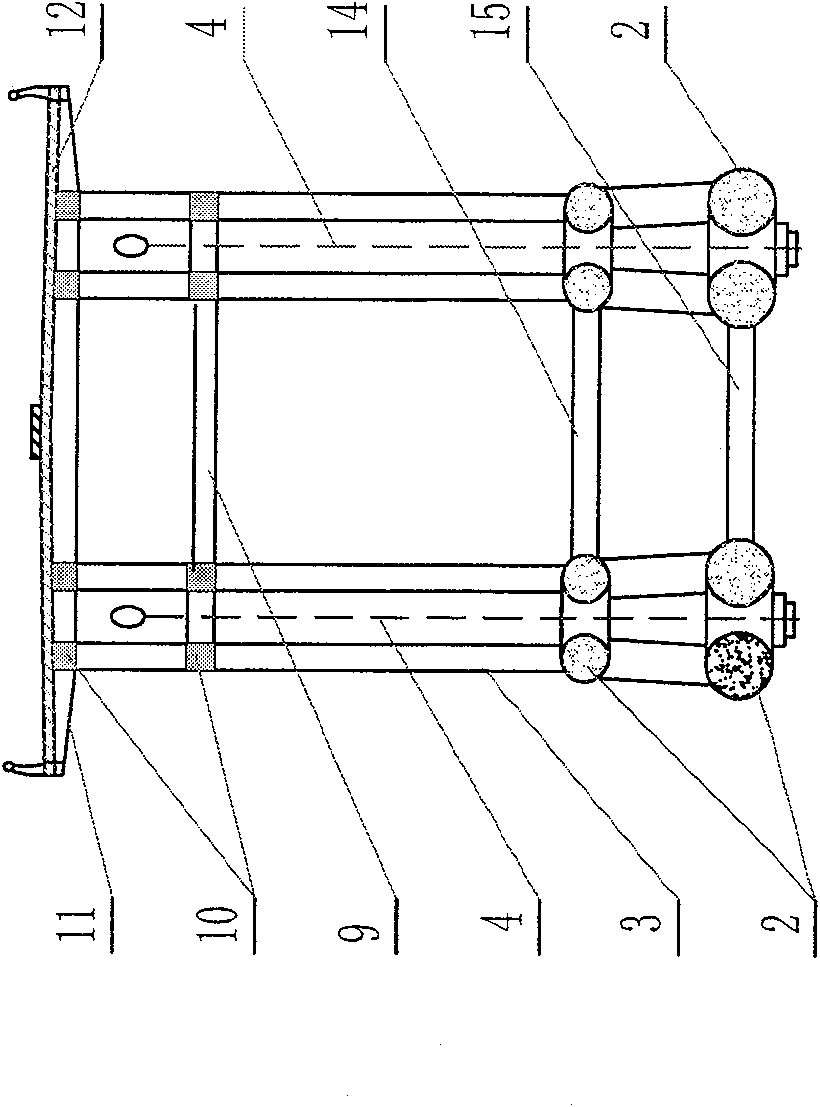

[0055] Example 2: The Xianshenhe Bridge is a large bridge spanning a 400-meter-deep valley on the Jinji Expressway. Due to the steep terrain, there is no construction site for the tunnel connecting the two abutments. It is designed as a 2×123m single-tower cable-stayed bridge, and the cost is as high as 9,000 ten thousand yuan. If the concrete truss cable-arch bridge with single-span 200m and four-tube truss structure is used instead according to local conditions, such as Figure 7 As shown, the 200m high bridge piers and tower columns can be canceled, saving more than 20 million yuan. This shows that in the V-shaped valley terrain, adopting the present invention not only has huge economic benefits, but also avoids the construction of deep water and high piers, and greatly shortens the construction period.

[0056] A concrete truss cable arch bridge with four steel pipe truss structures as the main arch ring image 3 and Figure 7 As shown: the lower chord steel pipe concre...

Embodiment 3

[0057] Embodiment 3: The concrete-filled steel tube cable composite arch bridge described in Embodiments 1 and 2 has a large self-weight, and the span of the main arch ring is limited to within 500 meters. A truss cable arch bridge with a steel box concrete truss main arch ring and an all-steel structure.

[0058] Guizhou Balinghe Bridge is a super-large bridge located in Guizhou on the main line of the Shanghai-Ruili National Highway. It is designed as a 248+1088+228=1564m steel truss stiffened girder suspension bridge. Due to the high mountains and deep valleys, the construction is quite difficult. If the "600m steel box truss concrete truss cable arch bridge" scheme is adopted, such as Figure 13 As shown, the large-scale special construction machinery and equipment for the suspension bridge can be eliminated, the construction period can be shortened, the investment can be saved, and a new way can be opened for the V-shaped valley super-span bridge. A concrete truss cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com