Integrated all-glass casing transducing element by converting solar energy to electrothermal energy

An energy conversion element, all-glass technology, applied in the field of solar energy applications, can solve the problems of short life, low efficiency, and high cost of photovoltaic cells, and achieve the effects of reducing building energy consumption, reducing junction temperature, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

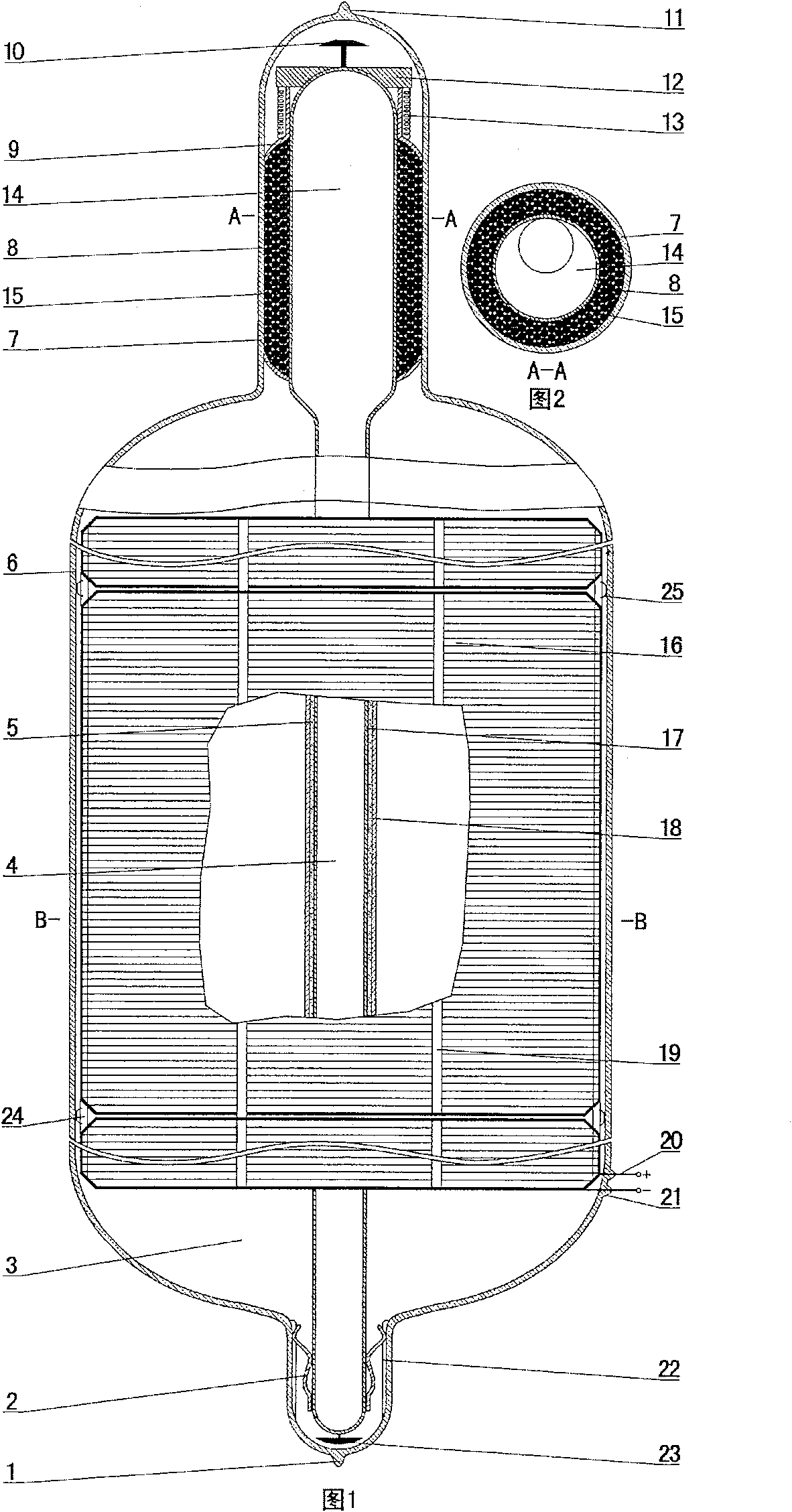

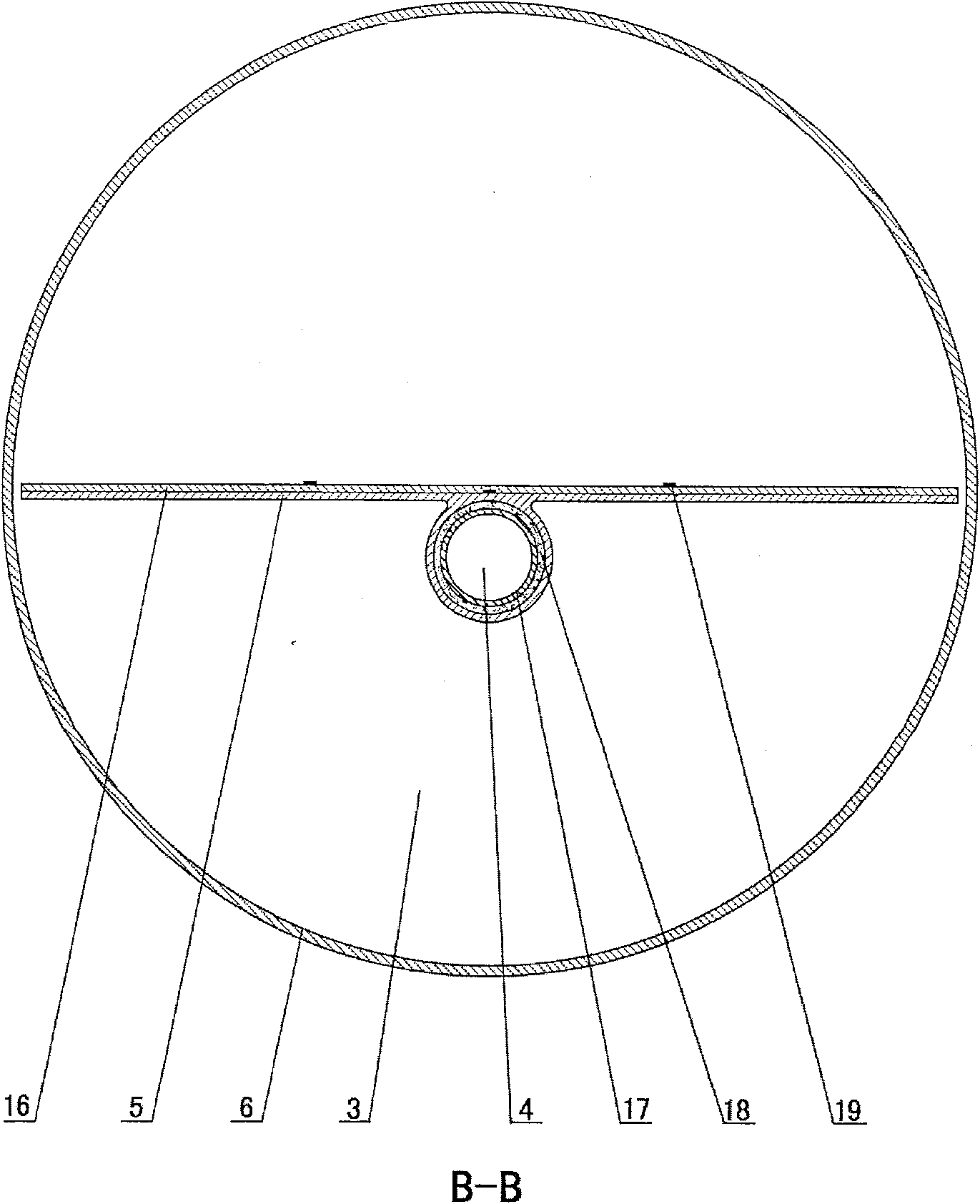

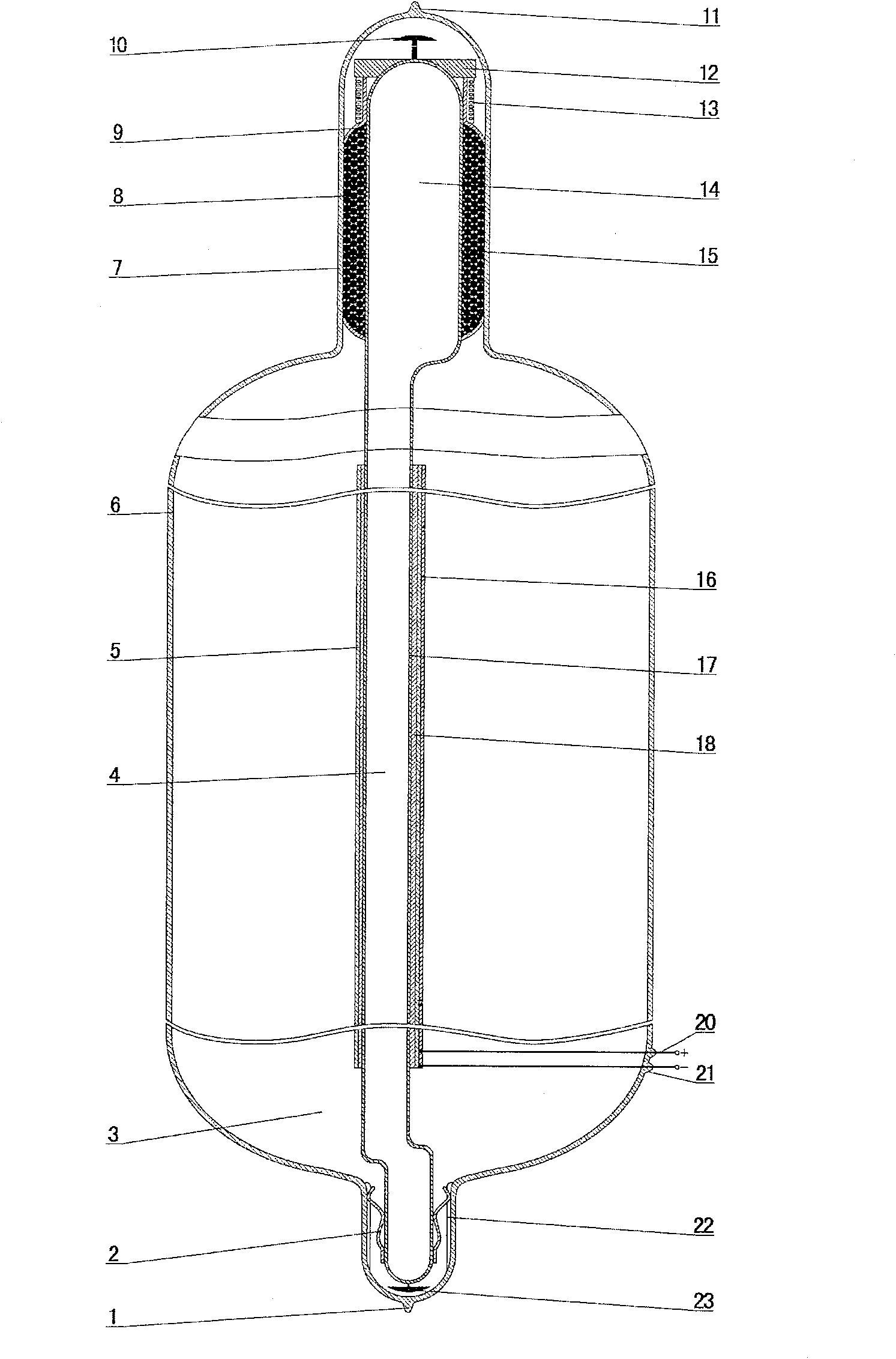

[0050] In the figure: 1 exhaust pipe sealing mouth, 2 metal positioning bullet clip, 3 vacuum ring cavity of glass heat collecting tube, 4 heat pipe cavity, 5 heat dissipation plate, 6 light-transmitting outer glass tube, 7 glass shell of heat releasing section of glass heat collecting tube, 8 Heat conduction particles, 9 heat conduction particles heat pipe metal container, 10 air getter, 11 glass heat collection tube exhaust tail pipe seal, 12 limit ring, 13 spring, 14 heat release section of heat pipe, 15 heat pipe throat wall, 16 photovoltaic cell, 17 Metal heat pipe, 18 heat transfer transition insulating filler, 19 wire, 20 glass sealing metal electrode, 21 glass metal sealing point, 22 positioning groove, 23 air getter, 24 glass buckle groove, 25 heat pipe support spring card, 26 glass sealing Electrode connector, 27 glass heat collecting tube heat-absorbing end protective cap, 28 metal heat pipe electrical connection wire, 29 glass heat collecting tube cap electrode insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com