Medium density fiber board made from bamboo and wood

A fiberboard, medium-density technology, used in fiber raw materials, fiber raw material processing, wood processing appliances, etc., can solve problems such as brittleness of wear-resistant paper or decorative paper, reduced production efficiency, and decreased mechanical properties, reducing raw material costs, The effect of saving wood and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through embodiment and accompanying drawing. It should be noted that these embodiments are not intended to limit the protection scope of the present invention, and the protection scope of the present invention shall prevail in the appended claims.

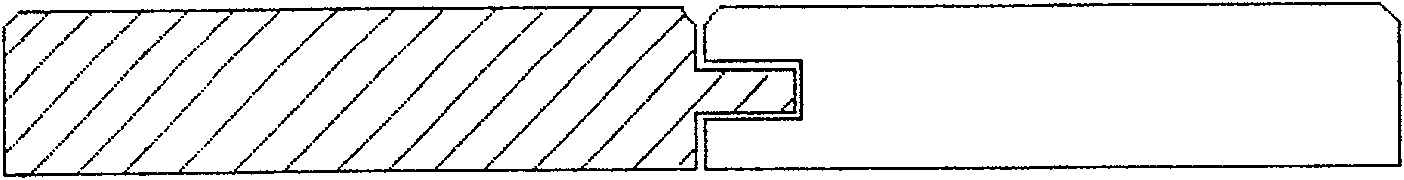

[0032] Fast-growing wood goes directly to the MDF continuous press line ( Figure 4), after peeling and slicing, enter the hopper of the thermal grinder; miscellaneous bamboo is sliced by a disc-type bamboo wood chipper, put into NaOH with a temperature of 120 ° C and account for 5% of the weight of the bamboo chip in an aqueous solution of 0.5 MPa under pressure for 15 min. , into the hopper of the thermal grinder, control the input ratio of miscellaneous bamboo slices and cedar cedar slices to be 1:1, and defibrillate through the thermal grinder to obtain a certain proportion of bamboo and wood mixed fibers; after drying (control the moisture content 12%), 21.5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com