Cold cathode fluorescent lamp, electrode unit and their manufacturing method

A technology for cold cathode fluorescent lamps and cylindrical electrodes, which is applied in the manufacture of cold cathodes, electrode systems, and hot electron cathodes, and can solve the problems of molybdenum or niobium being expensive, difficult to restore, and reduced heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

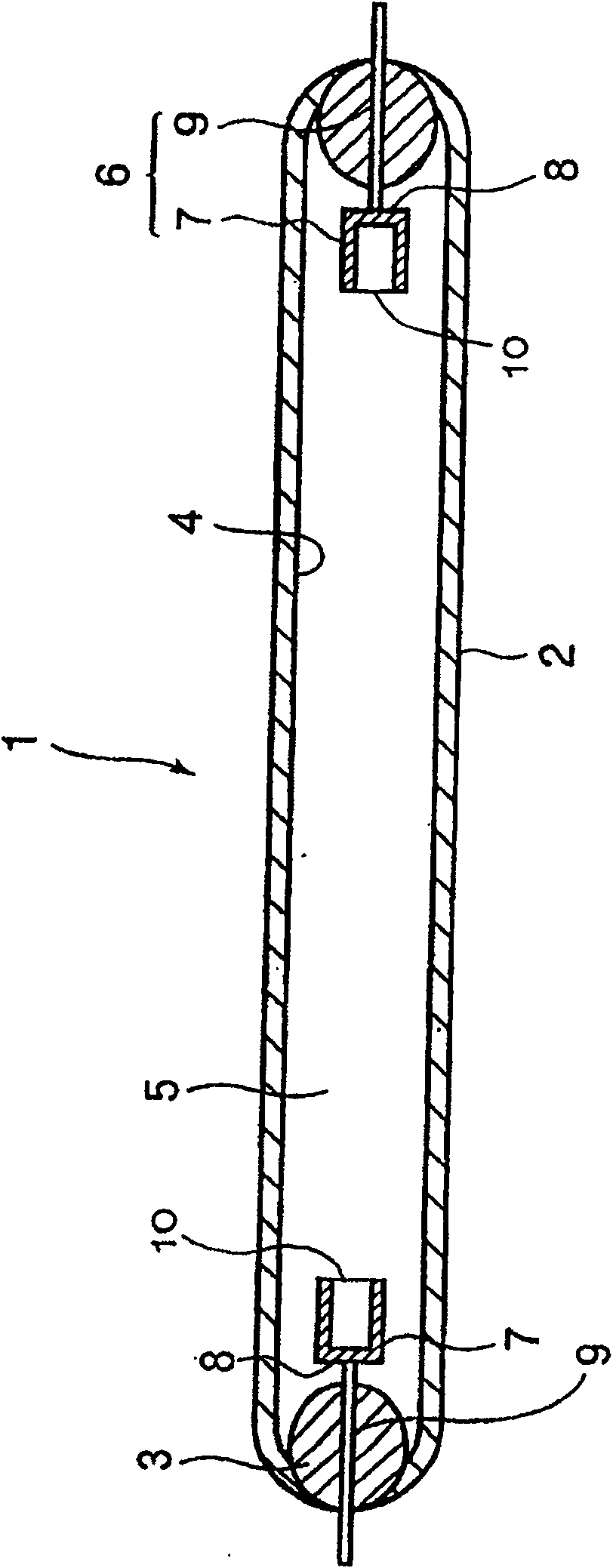

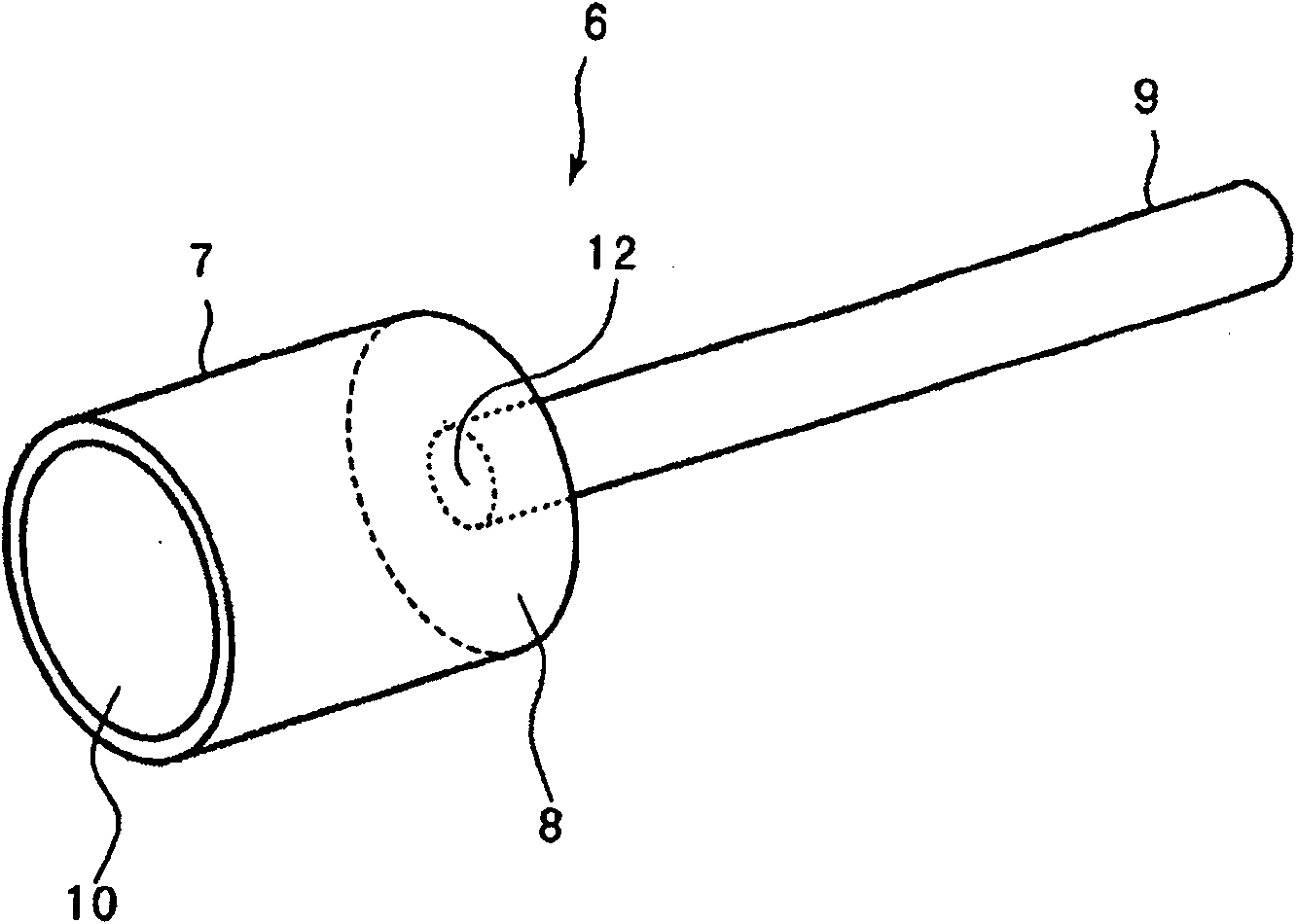

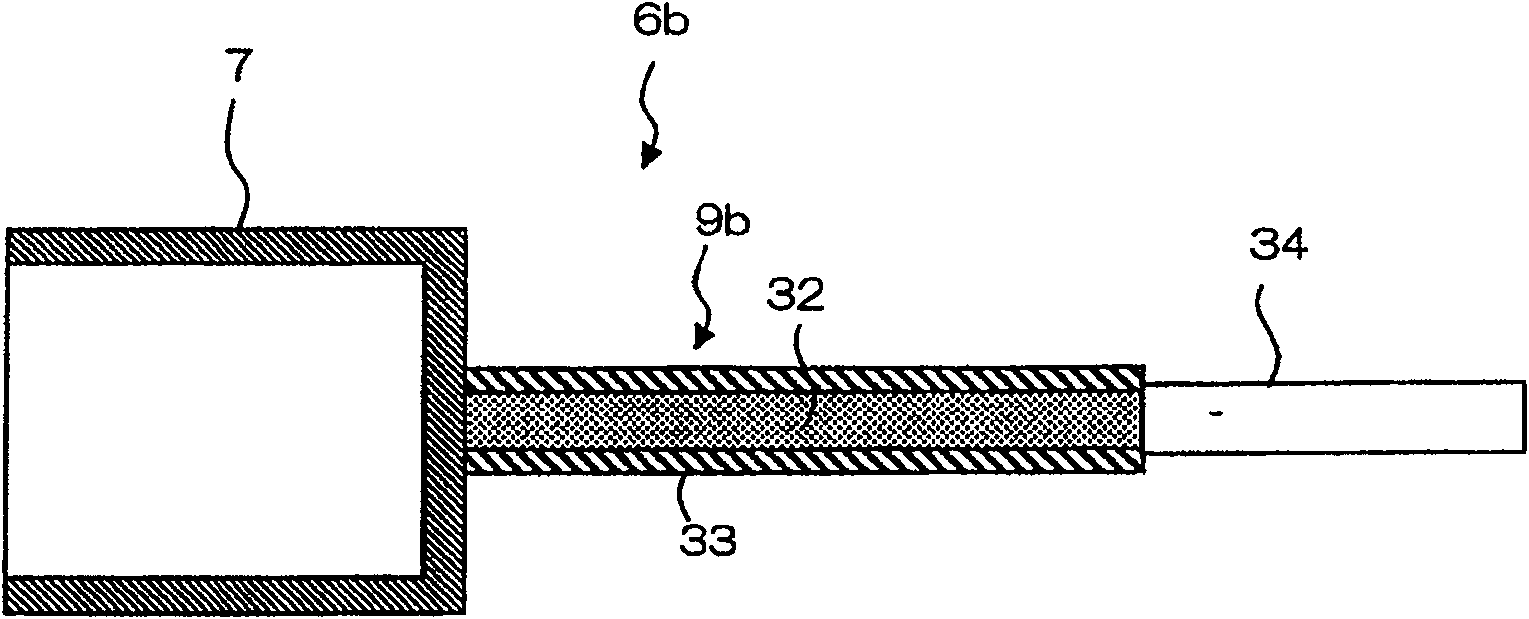

[0018] Hereinafter, an example of an embodiment of the cold cathode fluorescent lamp of the present invention will be described in detail with reference to the drawings. The cold-cathode fluorescent lamp in this example is suitable for use as a backlight of a liquid crystal panel, but it is also applicable to cold-cathode fluorescent lamps for other purposes. figure 1 It is a cross-sectional view showing a schematic structure of the cold cathode fluorescent lamp 1 in this example.

[0019] The cold cathode fluorescent lamp 1 has a basic structure in which both ends of a glass tube 2 made of borosilicate glass are hermetically sealed with sealing glass (solder glass 3 ). The outer diameter of the glass tube 2 is in the range of 1.5 to 6.0 mm, preferably in the range of 1.5 to 5.0 mm. The material of the glass tube 2 can be lead glass, soda-lime glass, low-lead glass and the like.

[0020] On the inner wall surface 4 of the glass tube 2, a phosphor layer not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com