High speed full-automatic paster machine array type mounting head

A placement head, array technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of restricting the popularization of technology, achieve compact and simple structure, reduce the center axis distance, and shorten the research and development cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

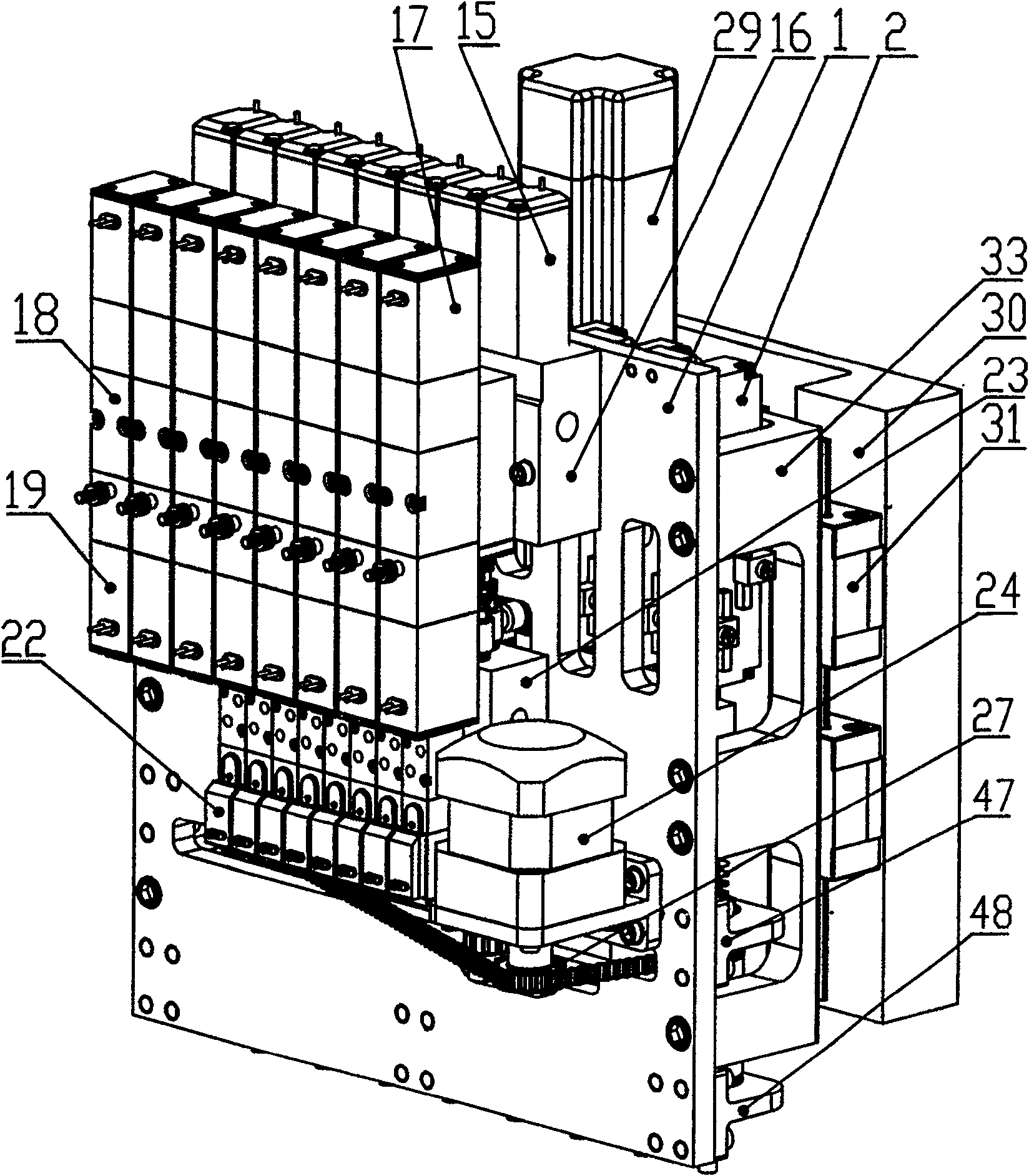

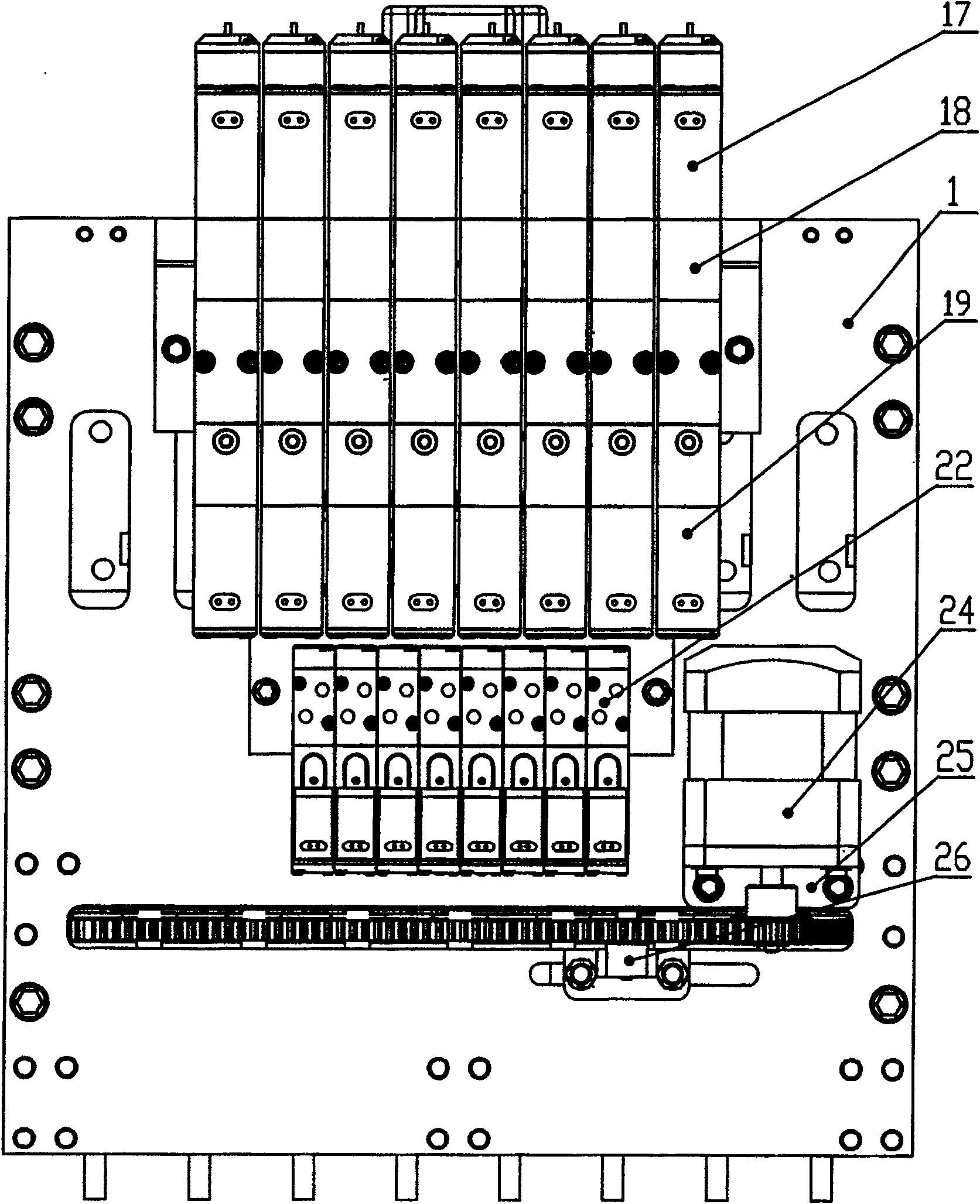

[0051] The placement head includes a main frame 1, a cylinder module, a ball spline module, a cylinder control module, a vacuum system, a θ angle control system, and an overall Z-axis motion system, and is characterized by:

[0052] like figure 1 , figure 2 As shown, the main frame 1 is a large plane with corresponding mounting threaded holes, an air channel on the upper part, and a timing belt channel on the lower part;

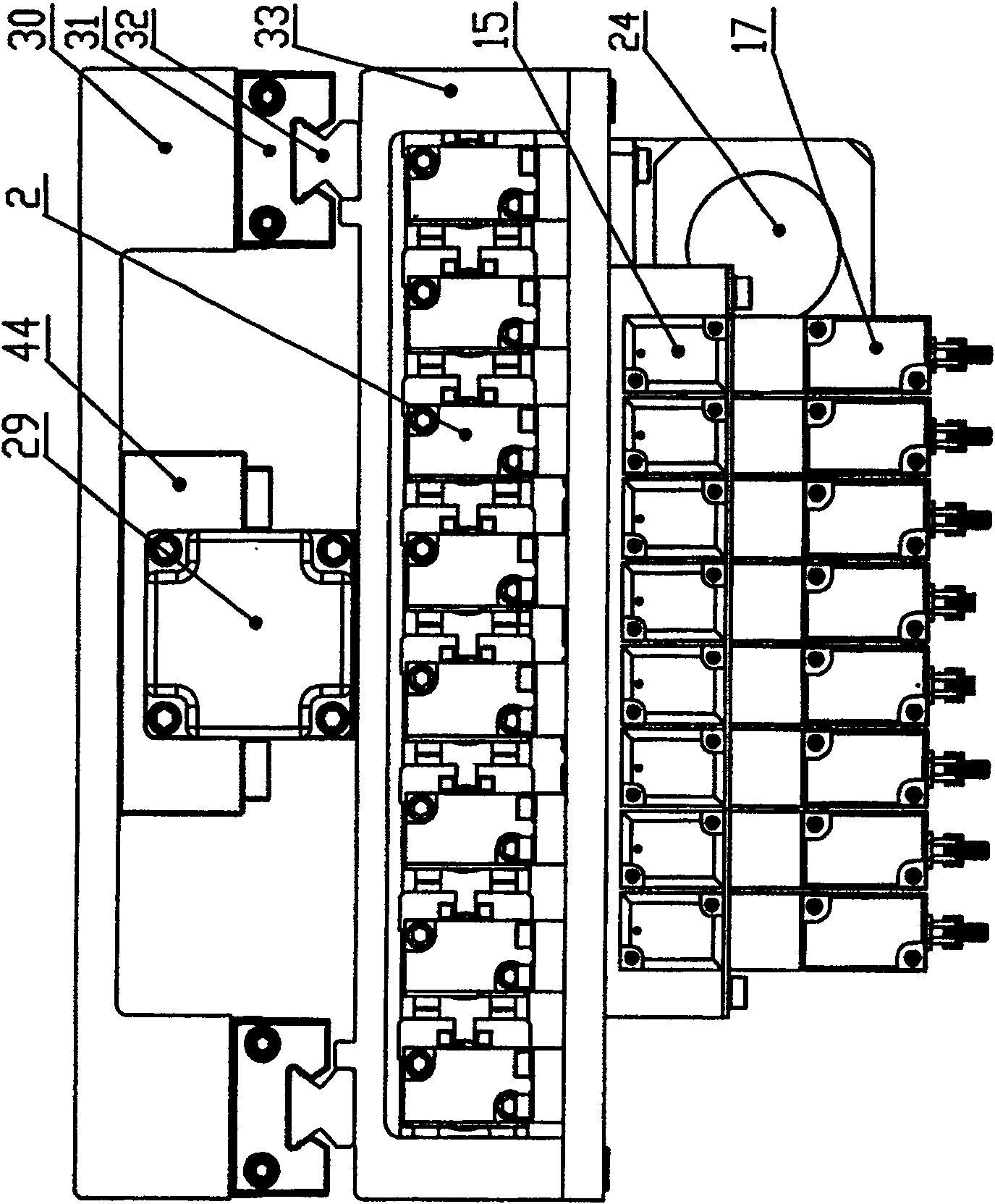

[0053] like Image 6 As shown, the cylinder module is a group of miniature precision square actuator cylinders 2 with magnetic switches 4, and the structure of the square actuator cylinders 2 is as follows: Figure 8 As shown, the piston rod is hollow, and there are 3 interfaces in total. A and B are piston movement vents, and C is a vacuum air supply port. Electromagnetic shielding plate 3, the piston rod of the square actuator cylinder 2 is a hollow piston rod that can conduct air, and a single group of cylinders is equipped with an electromagnetic shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com