Anchorage cable stretching automatic monitoring system

An automatic monitoring system and tensioning technology, applied in general control system, control/adjustment system, installation of anchor rods, etc., can solve the problems of high labor intensity, inability to measure elongation value, low precision, etc., and achieve deformation and tension distortion. Small rate, ensure timeliness and authenticity, reduce the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This embodiment is described separately according to the following parts.

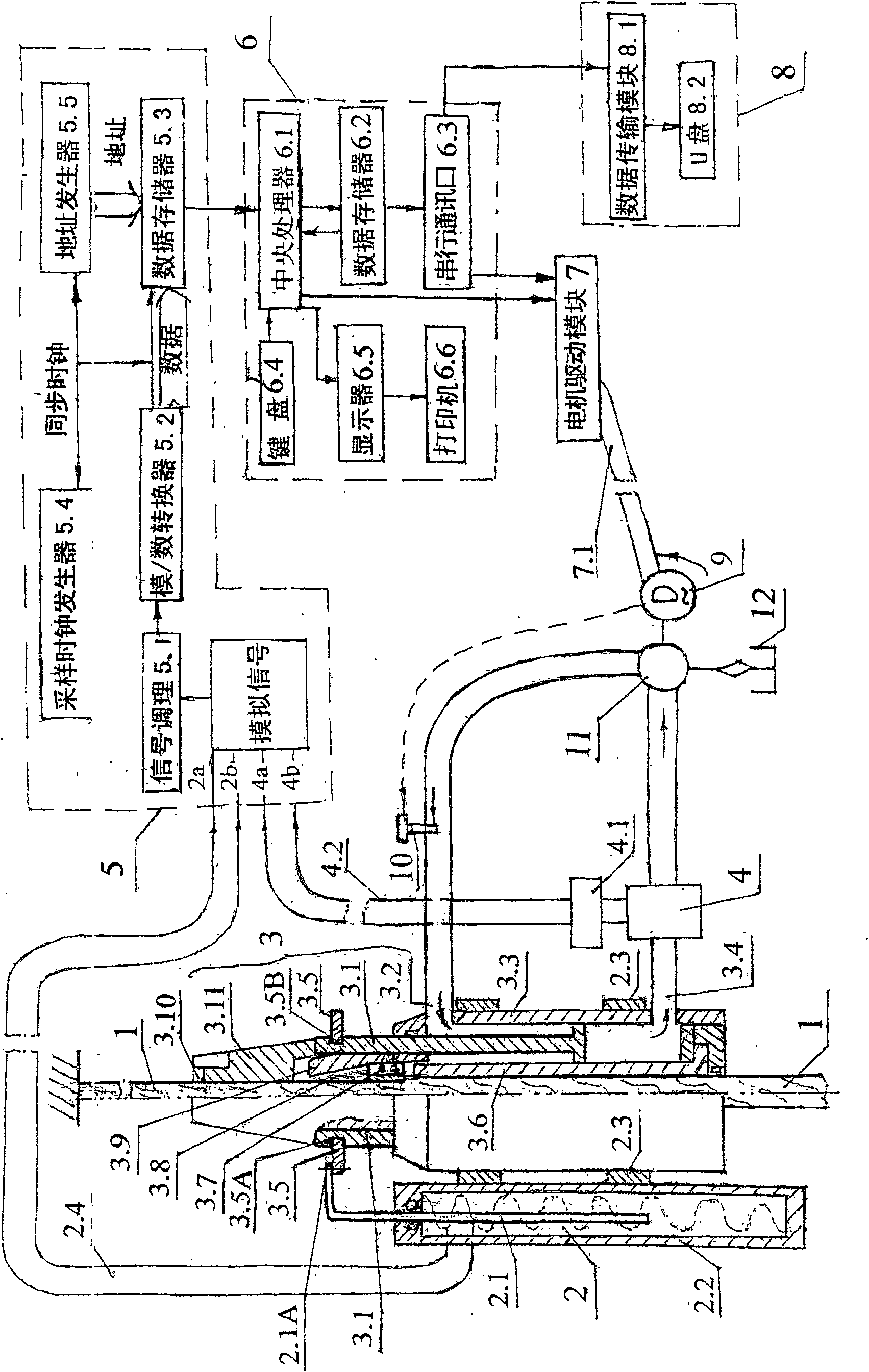

[0012] (A) Displacement measurement: see figure 1 , the steel strand 1 passes through the center of the prestressed jack 3, the jack model is YDC 240Q, which is equipped with an oil cylinder 3.3, a piston 3.1, a bushing 3.6, a return spring 3.7, a clip 3.8, an anchor ring 3.9, and a support sleeve nut 3.10 and support sleeves 3.11 etc. The displacement sensor is rod-type inductive displacement sensor 2, the maximum displacement is 200mm, the accuracy is 0.1%, the model is H-250, the displacement sensor 2 is installed and fixed on the jack 3 cylinder body 3.3 through the clamp 2.3 along the axial direction, and the clamps are two fixed on The displacement sensor housing 2.2 is hooped on the connecting ring 2.3 on the cylinder body. A concave ring groove is opened at the front end of the piston, and a circular ring 3.5 as the outer ring of the sliding bearing is embedded in the ring groove, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com