Heavy metal waste water continuous treating method and treating device thereof

A treatment method and a technology of a treatment device, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of difficult recovery of heavy metal residues, difficulty in meeting discharge standards, secondary pollution of the environment, etc. problems, to achieve the effects of small footprint, low operating costs and energy consumption, and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated below by way of examples.

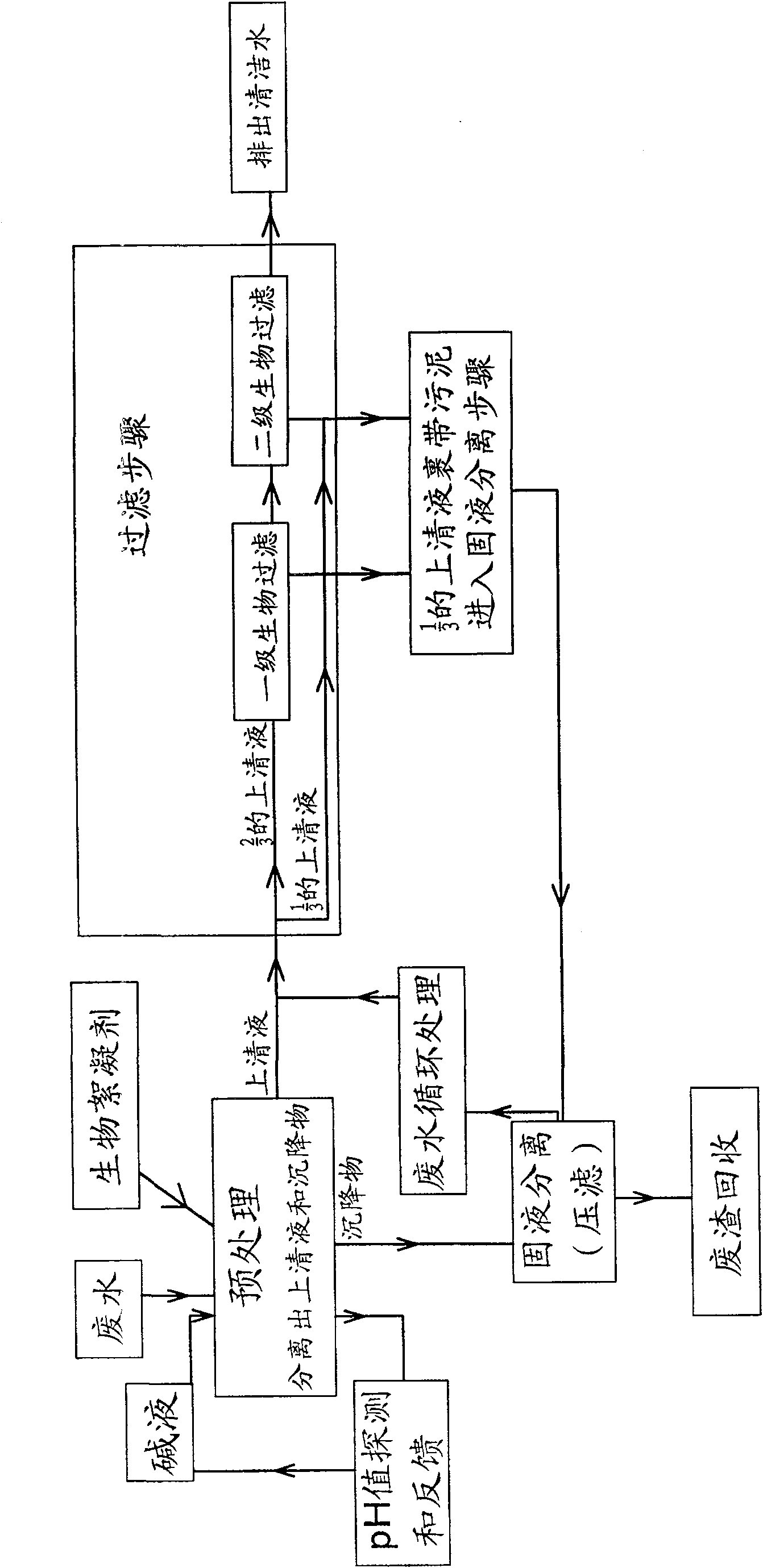

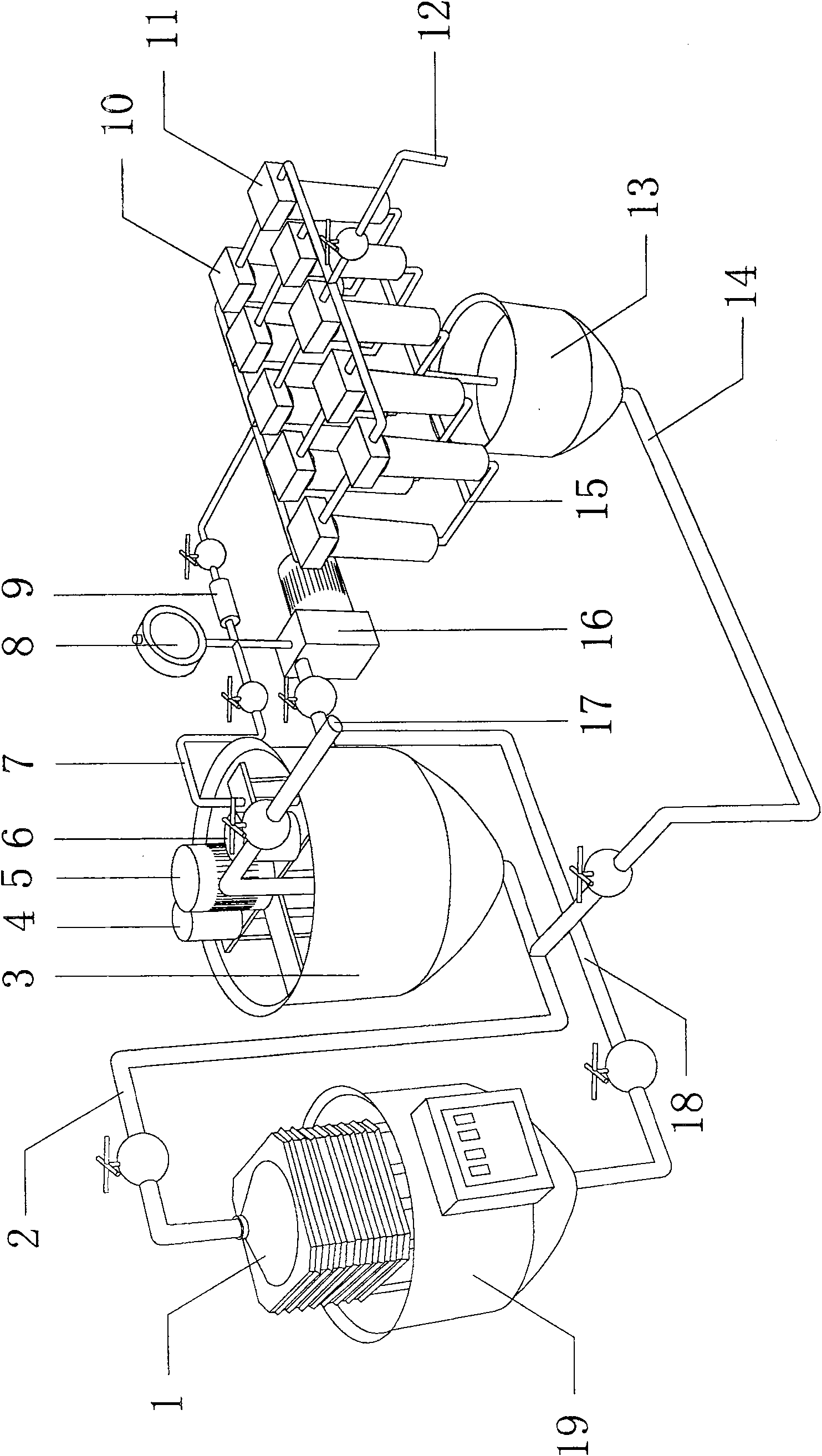

[0025] as attached figure 1 And attached figure 2 As shown, the heavy metal-containing wastewater enters the treatment device of the present invention from the wastewater inlet 17, and first completes the pretreatment in the wastewater storage tank 3. This pretreatment step includes adjusting the pH value of the wastewater and flocculating using a biological flocculant to settle metal ions in the wastewater. Therefore, the waste water storage tank 3 includes a liquid alkali storage tank 4 , a flocculant storage tank 6 and an electric mixer 5 . A pH value detection and feedback device is set at the bottom of the waste water storage tank 3, and according to the detected pH value of the waste water, lye is added from the liquid alkali storage tank 4 to the waste water stored in the waste water storage tank 3, Adjust the pH of the wastewater to 6.5-7.0. The γ-polyglutamic acid biological flocculan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com