Efficient flatting agent based on quartz powder and its preparation method and uses

A matting agent and quartz technology, applied in the field of high-efficiency matting agents, can solve the problems of high manufacturing resource and energy consumption, increased paint viscosity, and limited share of energy, and achieve low manufacturing cost, expanded pore volume, and high practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

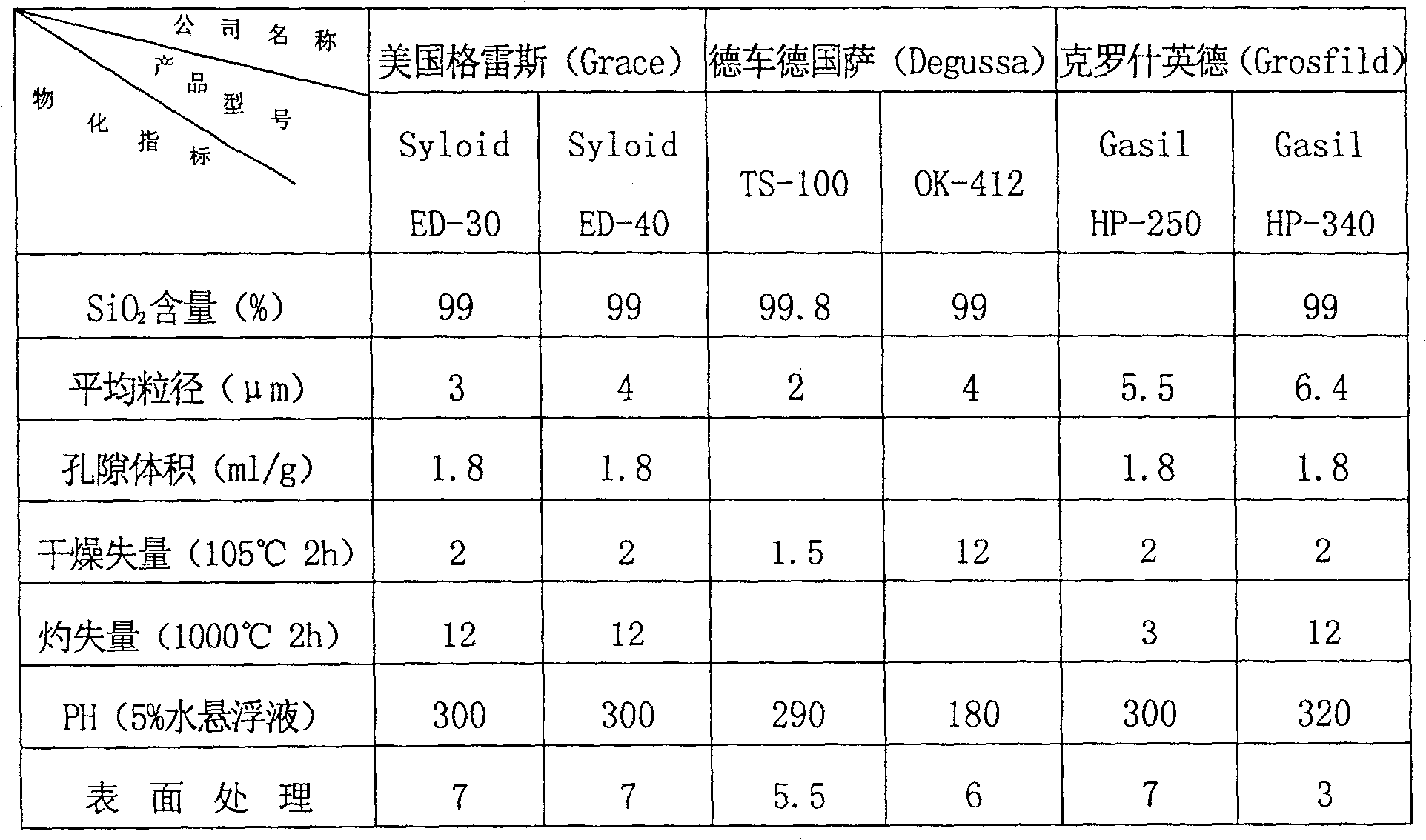

Image

Examples

Embodiment 1

[0030] In the present invention, the powdered quartz mineral raw material after mining and selection is firstly processed, added with water and stirred to make pulp, and then added grinding aid to continue stirring through multiple series-connected stirring mills, a part of the raw material is directly press-filtered, and the other part of the raw material is then added with acid and bleached After washing, press filtration is also carried out. The raw material after pressure filtration can be dried and dehydrated to directly obtain high-crystalline micro-silica powder, or after drying and dewatered, synthetic wax can be added to obtain modified micro-silica powder after surface modification. Silica fume. The modifying agent can be polyethylene wax, the dosage is 1-2%, the modification temperature is 80°C-90°C, and the modification time is 20-40min. Material particle size ≤10μm.

[0031] This product has good matting performance and can be used in paints and inks. It is an id...

Embodiment 2

[0033] The usage method of the present invention:

[0034] First wet the powder quartz high-efficiency matting agent with a solvent, add it to the resin, and disperse it in a high-speed disperser for 10-15 minutes, the dispersion speed is 1000-1200 rpm, and the line speed is about 5m / s.

[0035] Amount added:

[0036] Semi-gloss: 3-5% by weight

[0037] Matt: 6-10% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com