Method of preparing alpha aluminium oxide fine powder by low temperature

A technology of alumina fine powder and alumina, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of not obtaining α-alumina and difficult application, and achieve short roasting time, less organic matter consumption, and low roasting temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

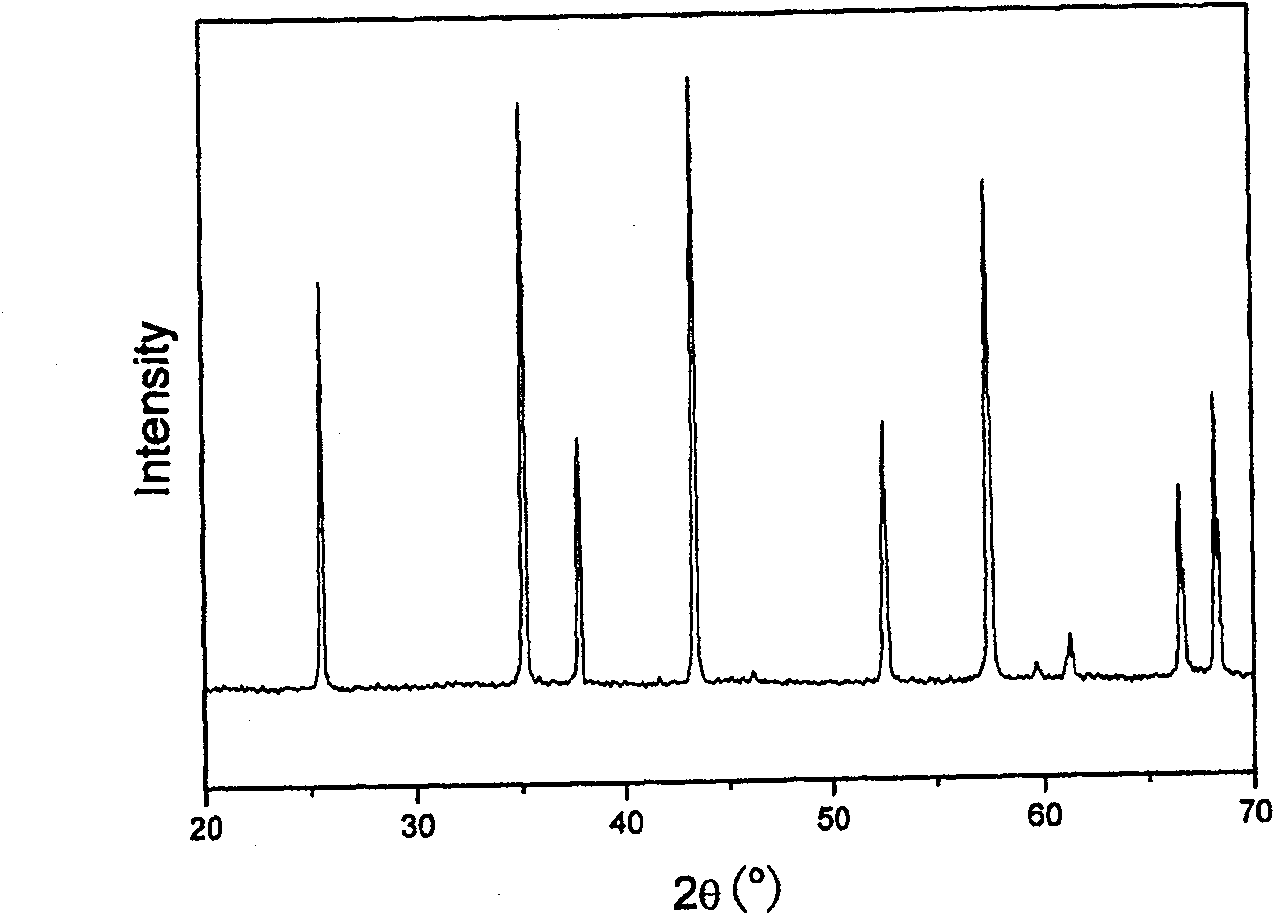

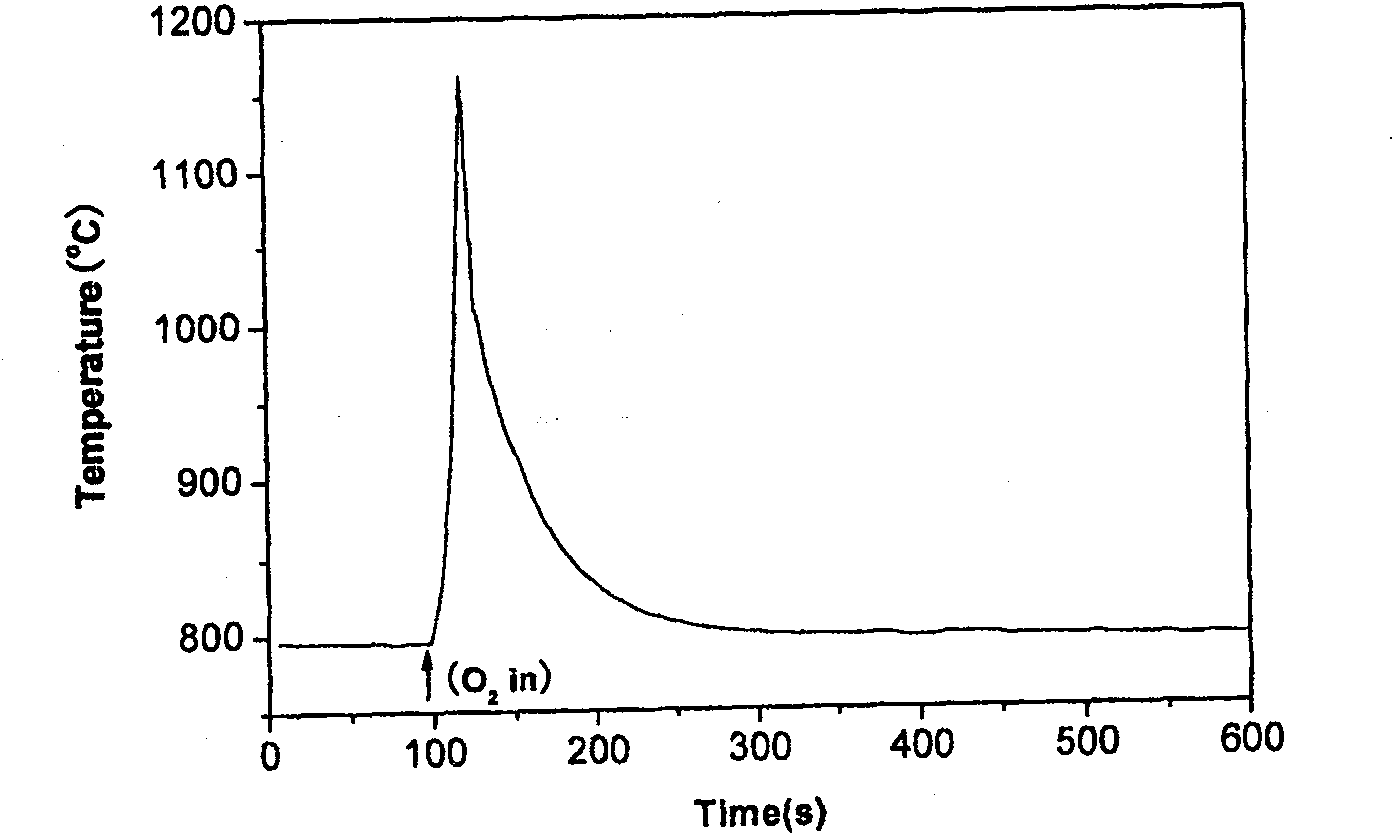

[0017] Add 10 g of pseudo-boehmite to 100 ml of 0.05 g / ml sucrose solution, stir and evaporate to dryness by heating in a water bath at 95°C. The evaporated sample was treated in a muffle furnace at 250°C for 2 hours, and then dehydrated and carbonized at 600°C for 4 hours under a nitrogen atmosphere to obtain a carbon / γ-alumina composite, thermogravimetric-differential thermal (TG-DTA) The results of the analysis showed that the carbon content in the composite was 6.8%. Take 1g of carbon / γ-alumina, put it into a vertical quartz bed reactor, raise the temperature to 800°C under the protection of nitrogen, keep it warm for about 10 minutes, and then feed 300ml / min of oxygen while maintaining the furnace temperature at 800°C After 10 minutes, the reaction was over. from figure 1 It can be seen from the X-ray diffraction characterization results that γ-alumina is completely transformed into α-alumina. Its specific surface area is 15m 2 / g. figure 2 is the temperature change...

Embodiment 2

[0019] Dissolve 5 g of soluble starch in 200 ml of deionized water, add 10 g of pseudo-boehmite, stir and evaporate to dryness by heating in a water bath at 95°C. The evaporated sample was dehydrated and carbonized at 600°C for 4 hours under a nitrogen atmosphere to obtain a carbon / γ-alumina composite. Take 1g of carbon / γ-alumina and put it in a vertical quartz bed reactor. Under the protection of the furnace, the temperature was raised to 800°C, kept for about 10 minutes, and then 300ml / min of oxygen was fed for 10 minutes while maintaining the furnace temperature at 800°C, and the reaction ended. γ-alumina is fully converted to α-alumina with a specific surface area of 5m 2 / g.

Embodiment 3

[0021] Add 10 g of γ-alumina to 100 ml of 0.05 g / ml sucrose solution, stir and evaporate to dryness by heating in a water bath at 95°C. The evaporated sample was treated in a muffle furnace at 250°C for 2 hours, and then dehydrated and carbonized at 600°C for 4 hours in a nitrogen atmosphere to obtain a carbon / γ-alumina composite. Take 1g of carbon / γ-alumina, put it into a vertical quartz bed reactor, raise the temperature to 800°C under the protection of nitrogen, keep it warm for about 10 minutes, and then feed 300ml / min of oxygen while maintaining the furnace temperature at 800°C After 10 minutes, the reaction was over. γ-alumina is fully converted to α-alumina with a specific surface area of 5m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com