Phosphor for white light LED and its prepn process

A phosphor and white light technology, applied in the field of white light LED, can solve the problems of inconvenient operation and high cost, and achieve the effect of wide excitation spectrum, broaden emission spectrum, and wide coverage of emitted light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (Ca 0.9 Eu 0.1 ) S Al 2 S 3 Synthesis of Phosphor Powder:

[0029] CaS: .0.1655g

[0030] Al: 0.1350g

[0031] Eu 2 o 3 : 0.0352g

[0032] S: 0.5000g

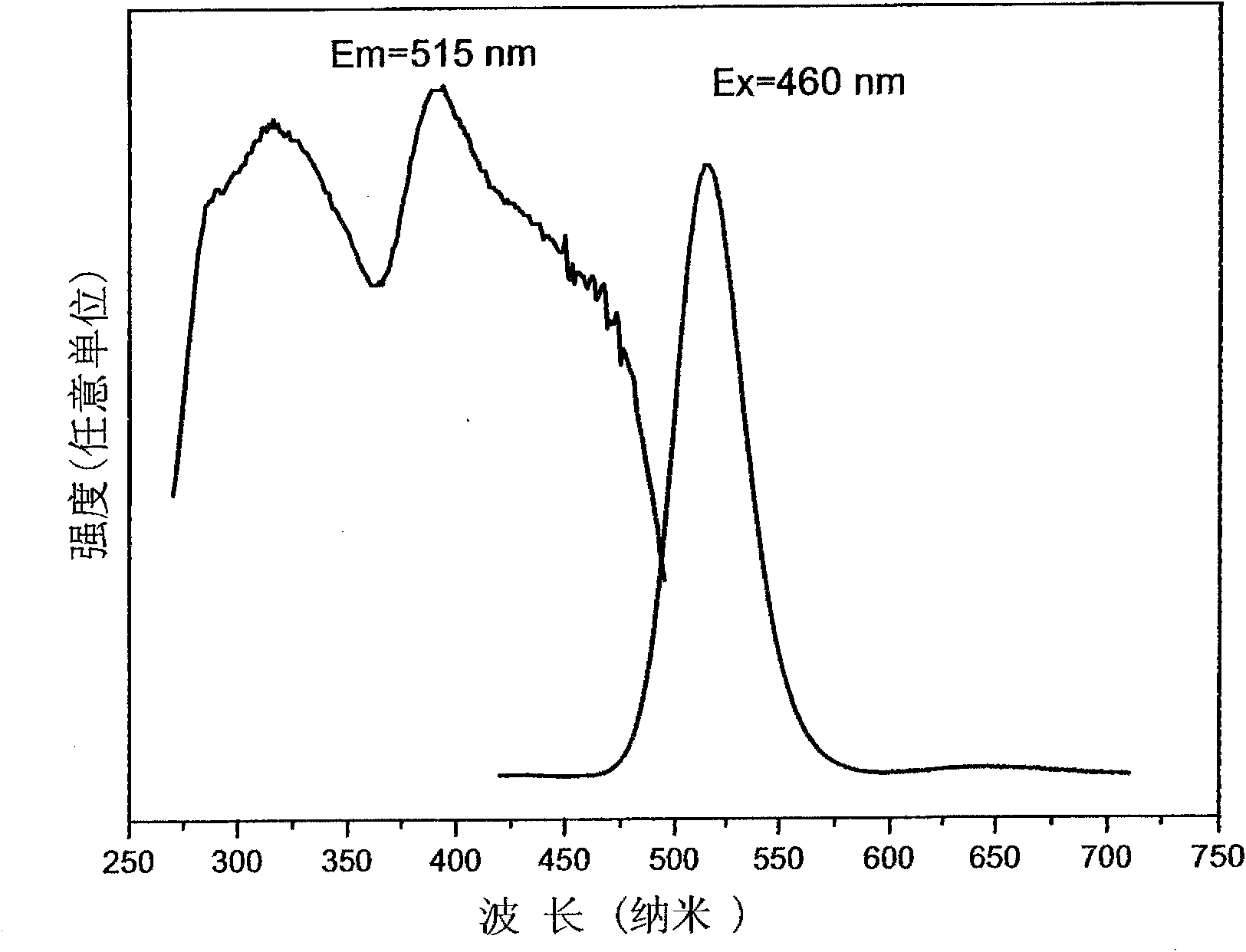

[0033] After grinding and mixing the raw materials of the mixture evenly, sintering at 1050°C for 1.5 hours in a hydrogen sulfide atmosphere, cooling, grinding evenly, and then crushing and sieving to finally obtain the product. figure 1 For the excitation and emission spectrum of the fluorescent powder, the excitation wavelength is 460nm.

[0034] White light LED packaging: mix the obtained phosphor powder with epoxy resin at a weight ratio of 1:2 to make a slurry, and then directly apply the slurry on the surface of the LED chip emitting blue light by coating, and finally cure it at 150°C, that is Get LED devices. Rare earth phosphors absorb light from blue LED chips and emit green light. Figure 4 It is the emission spectrum of the green LED with the change of driving current (5, 10, 20, 30, 40, 50mA).

Embodiment 2

[0036] (Zn 0.9 Eu 0.1 ) S Al 2 S 3 Synthesis of Phosphor Powder:

[0037] ZnS: 0.2192g

[0038] Al: 0.1350g

[0039] Eu 2 o 3 : 0.044g

[0040] S: 0.6000g

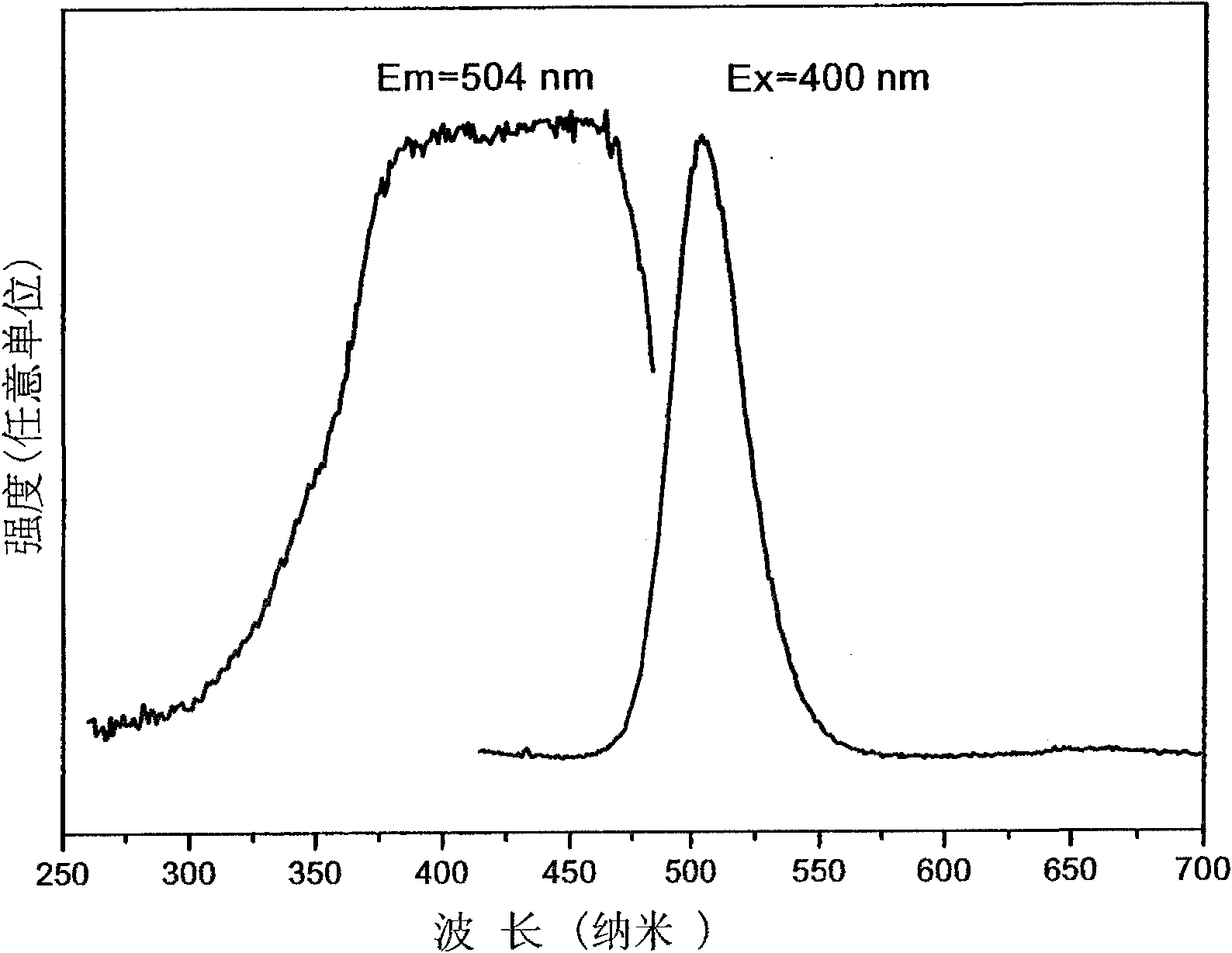

[0041] After grinding and mixing the raw materials of the mixture evenly, sintering at 980° C. for 3 hours in a hydrogen sulfide atmosphere, cooling, grinding evenly, and then crushing and sieving to finally obtain the product. figure 2 For the excitation and emission spectrum of the phosphor powder, the excitation wavelength is 400nm. Figure 5 The emission spectrum at room temperature of the green LED made of the fluorescent powder sealed tube of Example 2 at a driving current of 20 mA.

Embodiment 3

[0043] (Sr0.999 Ce 0.001 ) S Al 2 S 3 Synthesis of Phosphor Powder:

[0044] SrO: 0.3882g

[0045] Al: 0.2025g

[0046] CeO 2 : 0.0006g

[0047] S: 0.8000g

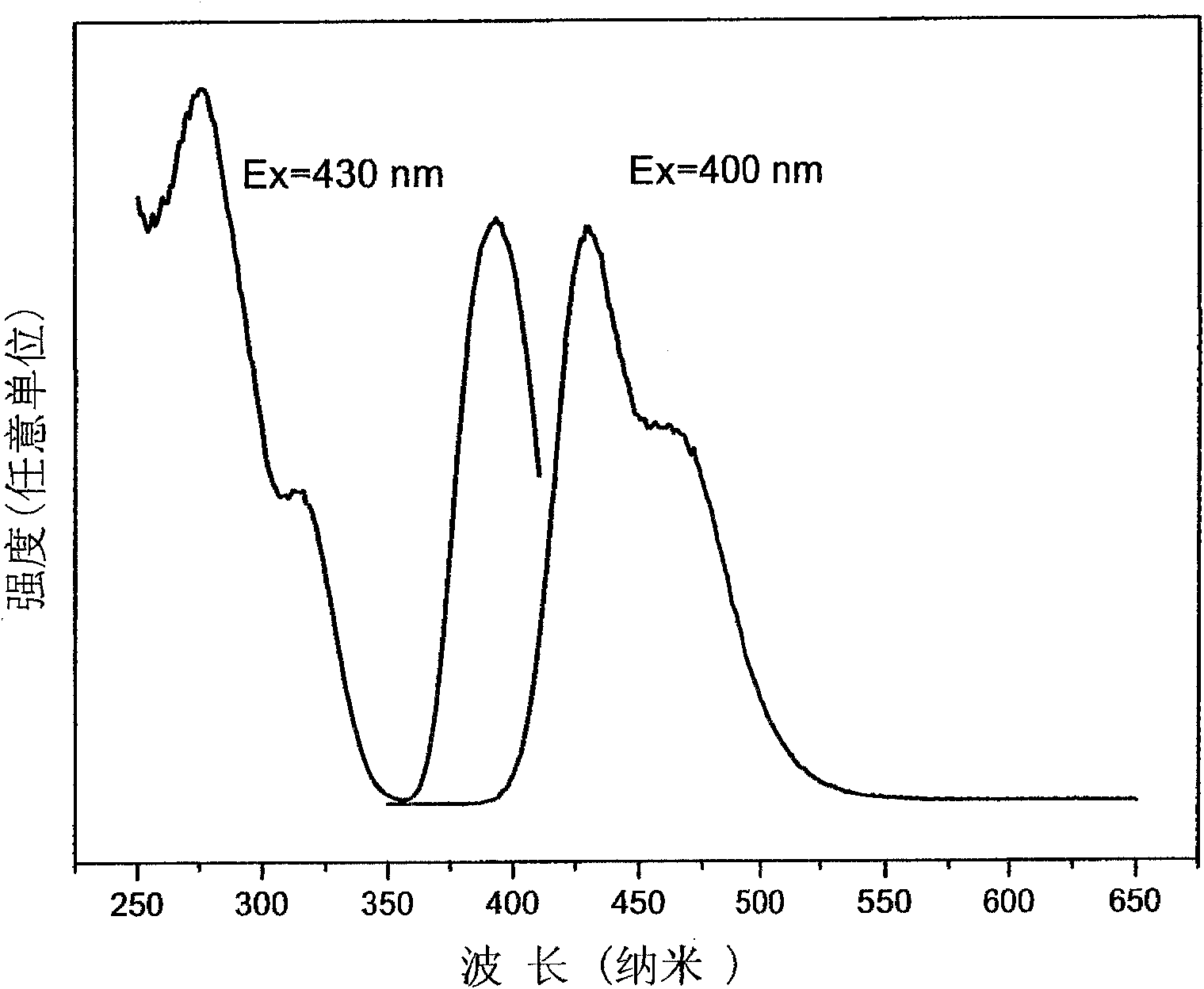

[0048] After grinding and mixing the raw materials of the mixture evenly, sintering at 1100°C for 2 hours in a hydrogen sulfide atmosphere, cooling, grinding evenly, and then crushing and sieving to finally obtain the product. image 3 For the excitation and emission spectrum of the phosphor powder, the excitation wavelength is 400nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com