Flour made of broom corn millet and its production method

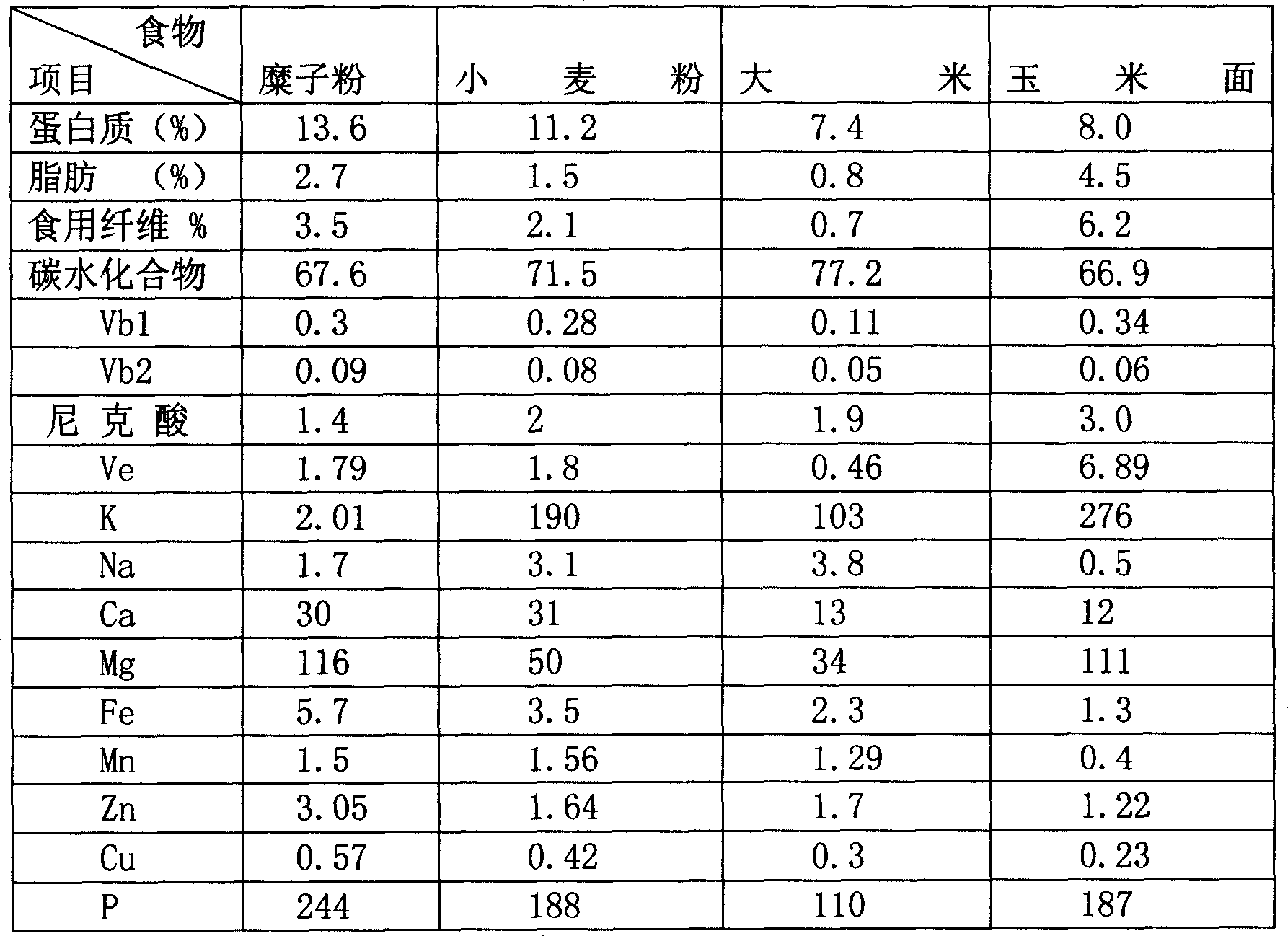

A technology of millet flour and rice flour, applied in the field of millet rice flour and its preparation, can solve the problems of single nutritional component of nutritious rice flour, lack of health care and disease prevention effects, lack of crude fiber, etc., and achieves long shelf life, preparation method and production. Simple process and the effect of maintaining human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A millet rice flour is made of millet powder, corn starch, white sugar and milk powder, wherein the addition of corn starch is 10% of the weight of the millet powder, the addition of white sugar is 10% of the weight of the millet powder, and the amount of the milk powder is The added amount is 15% of the weight of millet powder, and its preparation method is as follows: (1) impurity removal and peeling: remove immature, mildew, shriveled, worm-eaten, and impurities in the raw materials, and peel them; (2) according to the dosage ratio Weighing the raw materials; (3) pulverizing the above-mentioned various raw materials; (4) then mixing the broomcorn powder with cornstarch, extruding and puffing, and drying; (5) pulverizing the obtained mixture, and then adding white sugar , milk powder and stir evenly; (6) packing to get the finished product.

Embodiment 2

[0019] A millet rice flour is made of millet powder, corn starch, white sugar and milk powder, wherein the addition of corn starch is 15% of the weight of the millet powder, the addition of white sugar is 15% of the weight of the millet powder, and the amount of the milk powder is The added amount is 25% of the weight of millet powder, and its preparation method is as follows: (1) impurity removal and peeling: remove immature, mildew, shriveled, worm-eaten, and impurities in the raw materials, and peel them; (2) according to the dosage ratio Weighing the raw materials; (3) pulverizing the above-mentioned various raw materials; (4) then mixing the broomcorn powder with cornstarch, extruding and puffing, and drying; (5) pulverizing the obtained mixture, and then adding white sugar , milk powder and stir evenly; (6) packing to get the finished product.

Embodiment 3

[0021] A millet rice flour is made from millet powder, corn starch, white sugar and milk powder, wherein the addition of corn starch is 12% of the weight of the millet powder, the addition of white sugar is 14% of the weight of the millet powder, and the amount of the milk powder is The added amount is 20% of the weight of millet powder, and its preparation method is as follows: (1) removing impurities and peeling: removing immature, mildew, shriveled, insect-eaten, and impurities in the raw materials, and peeling; (2) according to the dosage ratio Weighing the raw materials; (3) pulverizing the above-mentioned various raw materials; (4) then mixing the broomcorn powder with cornstarch, extruding and puffing, and drying; (5) pulverizing the obtained mixture, and then adding white sugar , milk powder and stir evenly; (6) packing to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com