Method for producing liquor egg product using non-thermal sterilization technology

A technology for liquid eggs and products, which is applied in applications, food preservation, egg preservation, etc. It can solve problems affecting product quality and achieve the effects of maintaining color, short processing time, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dip the eggs whose shells are intact after inspection into warm water at 30°C and wash them, then wash the eggshells with 50 mg / L chlorine water at 30°C, dry them at room temperature, beat the eggs and collect the liquid eggs aseptically, stir them evenly to obtain To process liquid eggs, the liquid eggs are vacuum degassed for 10 minutes, and ultrafiltration desalination is performed with an ultrafiltration membrane with a relative molecular mass cut-off of 3000, and the conductivity is reduced by 0.15sm -1 After the field strength is 40kV / cm -1 , frequency is 100Hz high-voltage pulsed electric field treatment 1600s, add 50IU / mL trace lysozyme after 1600s, aseptic canning obtains liquid egg product.

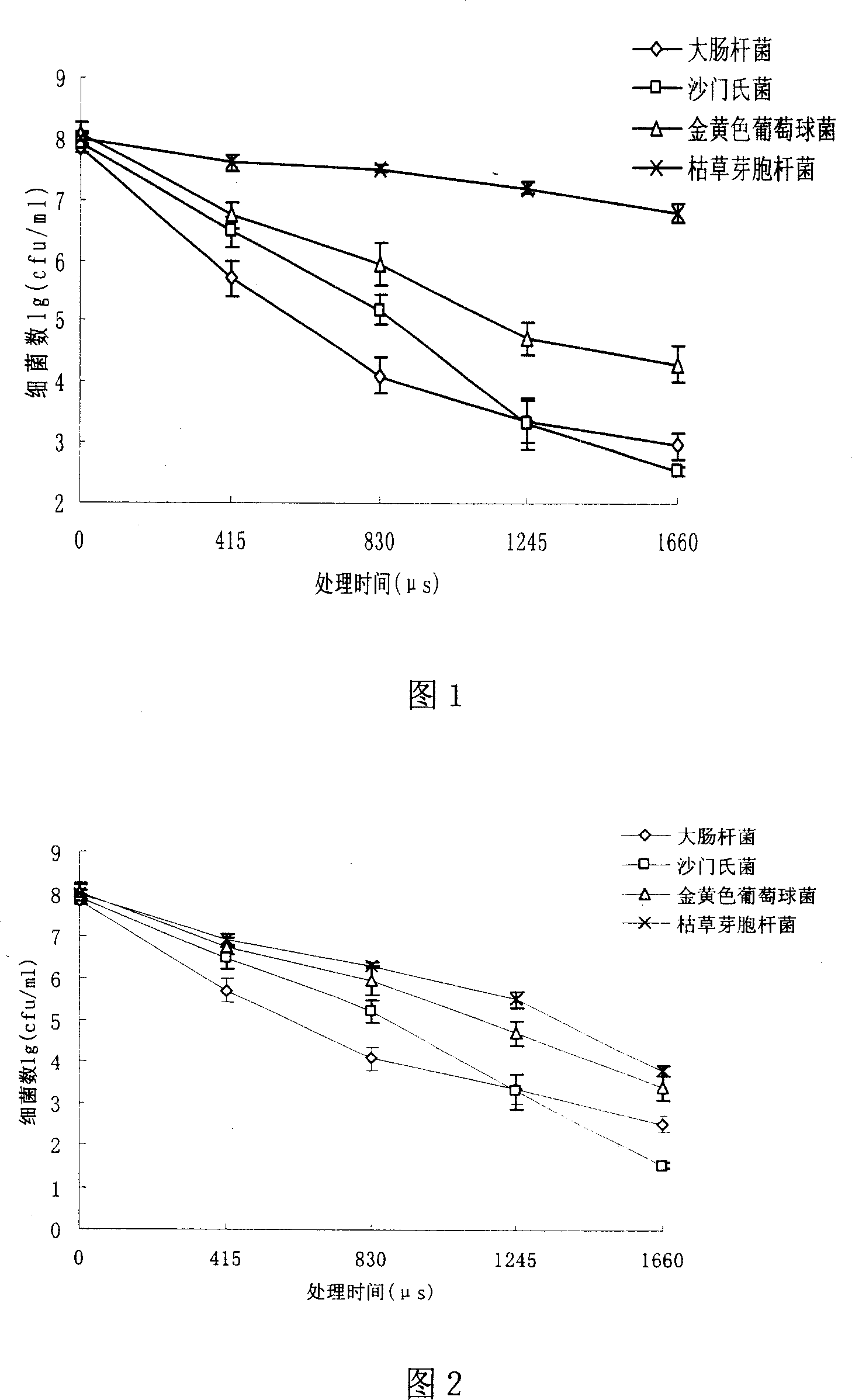

[0031] Figure 1 shows the bactericidal effect of high-voltage pulsed electric field treatment on liquid eggs inoculated with different microorganisms. As shown in the figure, as the action time increases, the number of microorganisms continues to decrease, and the total ...

Embodiment 2

[0039] Dip the eggs with intact eggshells in 10°C warm water and wash them, then wash the eggshells with 200 mg / L chlorine water at 10°C, dry them at room temperature, beat the eggs and collect the liquid eggs aseptically, stir them evenly to obtain To process liquid eggs, liquid eggs are degassed by ultrasonic waves with a power of 400W for 20 minutes, and ultrafiltration desalination is performed with an ultrafiltration membrane with a relative molecular mass cut-off of 5000, and the conductivity is reduced by 0.3sm -1 After the field strength is 60kV / cm -1 1. Add 20IU / mL trace amount of lysozyme after 200s of high-voltage pulsed electric field treatment with a frequency of 10 Hz, and aseptically bottled to obtain a liquid egg product.

Embodiment 3

[0041]Dip the eggs whose shells are intact after inspection into warm water at 20°C and wash them, then wash the eggshells with 100 mg / L chlorine water at 20°C, dry them at room temperature, beat the eggs and collect the liquid eggs aseptically, stir them evenly to obtain To process liquid eggs, liquid eggs are degassed in vacuum for 5 minutes, and ultrafiltration desalination is performed with an ultrafiltration membrane with a relative molecular mass cut-off of 1000, and the conductivity is reduced by 0.1sm -1 After the field strength is 20kV / cm -1 1. Add 200IU / mL trace lysozyme after 1000s of high-voltage pulsed electric field treatment with a frequency of 500Hz, and aseptically bottled to obtain a liquid egg product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com