Laser impact repairing device and method for damaged metal blade

A laser shock and blade technology, applied in the field of mechanical manufacturing and laser processing applications, can solve problems such as repair of metal blade knots, and achieve the effect of increasing fatigue life, improving fatigue life and good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

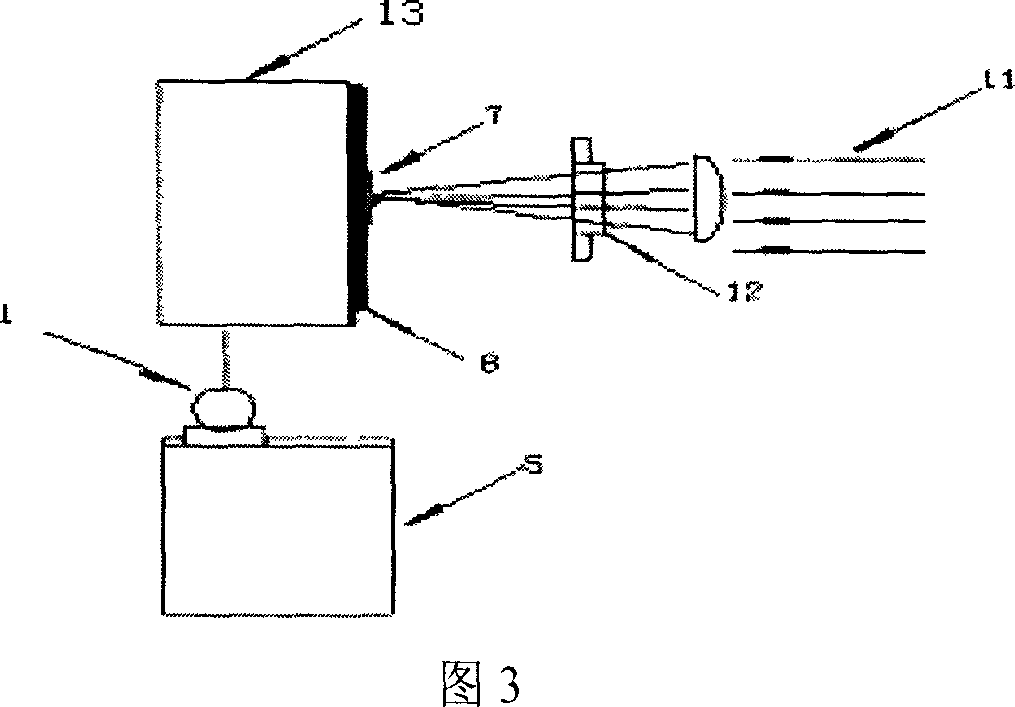

[0023] As shown in Figure 3, laser shock repairs the damaged aircraft blade (13). The material of the aircraft blade (13) is titanium alloy Ti6Al4V, and the blade (13) has cracks with a width of 0.2 mm and a length of 0.9 mm on the air inlet edge. Since the fatigue strength of the blade (13) obviously decreases after damage, the length of the crack becomes exponentially longer with the increase of the number of cycles, and the crack will break soon. In the process of laser shock repair, the laser output wavelength is 1.054 μm, the pulse width (FWHM) of the output laser is 22.1 ns, and the laser pulse energy is about 35 J. At the repairing part of the blade (13), the repairing device positions the blade (13) and the light spot according to the instruction of the repairing device. -(C 2 h 5 O) 4 Si polymer is attached to the part to be repaired. After laser shock repair, the cleaning brush (2) cleans and removes the residual flexible patch on the repaired part of the blade (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com