Nickel oxide mixed with cobalt manganese hydroxy base and preparation method thereof

A technology of cobalt manganese hydroxyl and nickel oxide, applied in chemical instruments and methods, nickel carbonyl, chemical/physical processes, etc., can solve problems such as polluting the environment, increasing costs, and affecting tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

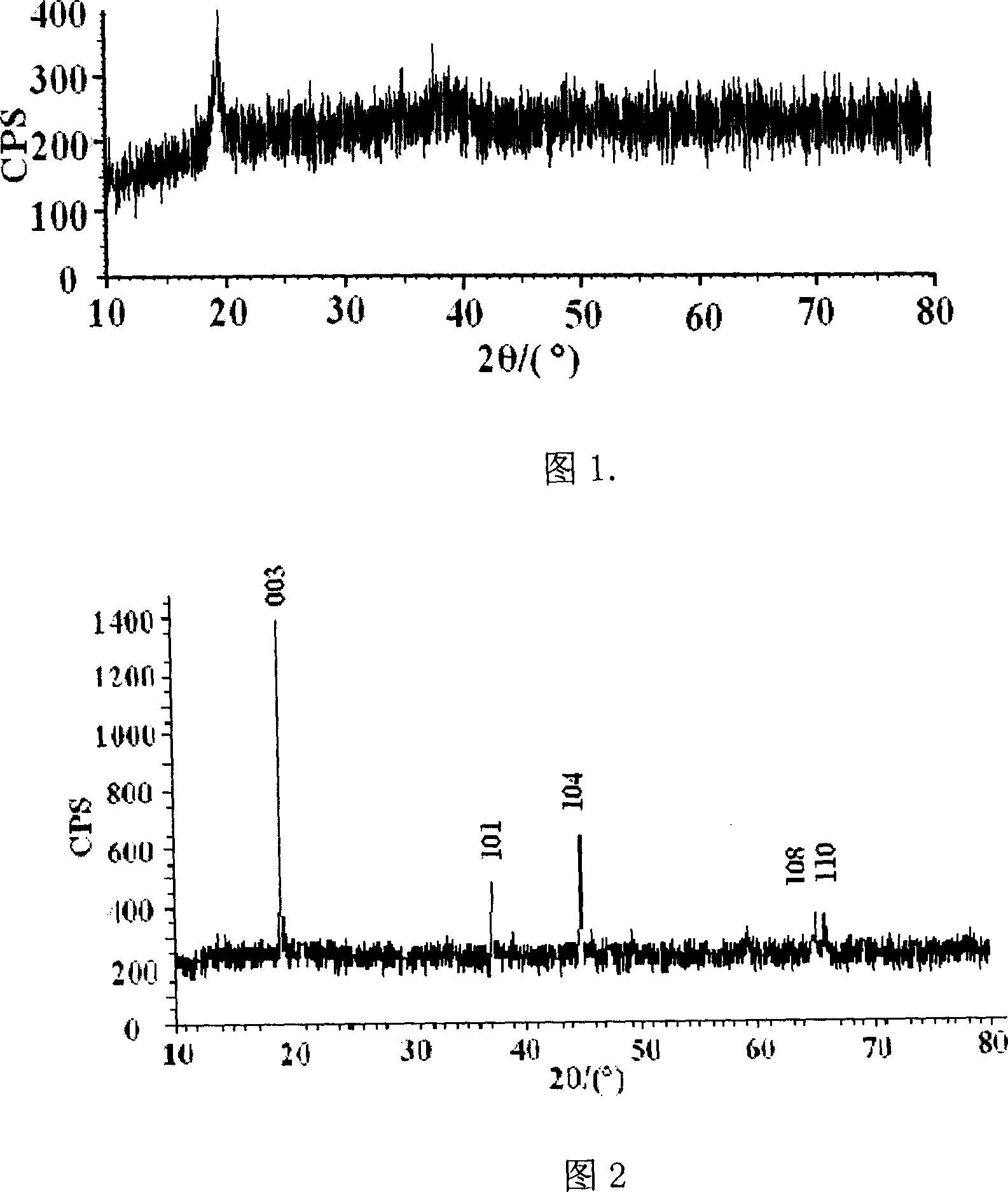

Image

Examples

Embodiment 1

[0008] (1) Solution preparation, preparation concentration is 4.0mol / dm 3 1000ml of NaOH solution; according to the ratio of Ni:Mn:Co molar ratio of 1:1:1, the concentration is 1.5mol / dm 3 NiSO 4 、CoSO 4 , MnSO 4 Mixed solution 1000ml.

[0009] (2) Put the above-mentioned sodium hydroxide solution into the reactor first, then gradually add the above-mentioned metal mixed salt solution into the reactor under stirring, set the reaction temperature at 50° C., and obtain doped Co, Mn nickel hydroxide paste.

[0010] (3) 100ml of 0.6% polyacrylamide solution was added to the obtained slurry for coagulation, and then the coagulation was press-filtered to form a filter cake.

[0011] (4) The above filter cake was dried at 120° C. for 6 hours, and then washed with water to remove soluble impurity ions.

[0012] (5) After drying for the second time at 120°C, crush and sieve to obtain Ni 1 / 3 co 1 / 3 mn 1 / 3 OOH precursor with a tap density of 2.21g / cm 3 .

Embodiment 2

[0014] (1) Solution preparation, preparation concentration is 6.0mol / dm 3 1000ml of KOH solution; according to the ratio of Ni:Mn:Co molar ratio of 2:2:1, the concentration is 1.5mol / dm 3 NiSO 4 、CoSO 4 , MnSO 4 Mixed solution 1000ml;

[0015] (2) Put the above-mentioned potassium hydroxide solution into the reactor first, then gradually add the above-mentioned metal mixed salt solution into the reactor under stirring, set the reaction temperature at 80° C., and obtain doped Co, Mn nickel hydroxide slurry;

[0016] (3) 120ml of 0.6% polyacrylamide solution is added to the resulting slurry for coagulation, and then the coagulation is press-filtered to form a filter cake;

[0017] (4) drying the above filter cake at 135°C for 4 hours, then washing with water to remove soluble impurity ions;

[0018] (5) After drying for the second time at 100°C, crush and sieve to obtain Ni 2 / 5 co 1 / 5 mn 2 / 5 OOH precursor with a tap density of 2.23g / cm 3 .

Embodiment 3

[0020] (1) Solution preparation, preparation concentration is 2.0mol / dm 3 1500ml of NaOH solution; according to the ratio of Ni:Mn:Co molar ratio of 2:1:2, the concentration is 1.2mol / dm 3 NiCl 2 、CoCl 2 , MnCl 2 Mixed solution 1000ml;

[0021] (2) Put the above-mentioned sodium hydroxide solution into the reactor first, then gradually add the above-mentioned metal mixed salt solution into the reactor under stirring, set the reaction temperature at 30°C, and obtain doped Co, Mn after 2 hours of reaction Nickel hydroxide slurry;

[0022] (3) 200ml of 0.3% polyacrylamide solution is added to the resulting slurry for coagulation, and then the coagulation is press-filtered to form a filter cake;

[0023] (4) The above filter cake was dried at 100° C. for 8 hours, and then washed with water to remove soluble impurity ions.

[0024] (5) After drying for the second time at 80°C, crush and sieve to obtain Ni 2 / 5 co 2 / 5 mn 1 / 5 OOH precursor with a tap density of 2.15g / cm 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com