Denitrified biological denitrificaion equipment of intensified internal source, and method

An endogenous denitrification and biological denitrification technology, applied in aerobic and anaerobic processes, can solve the problems of high sludge production and low denitrification efficiency, achieve low sludge production, improve denitrification efficiency, The effect of saving infrastructure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

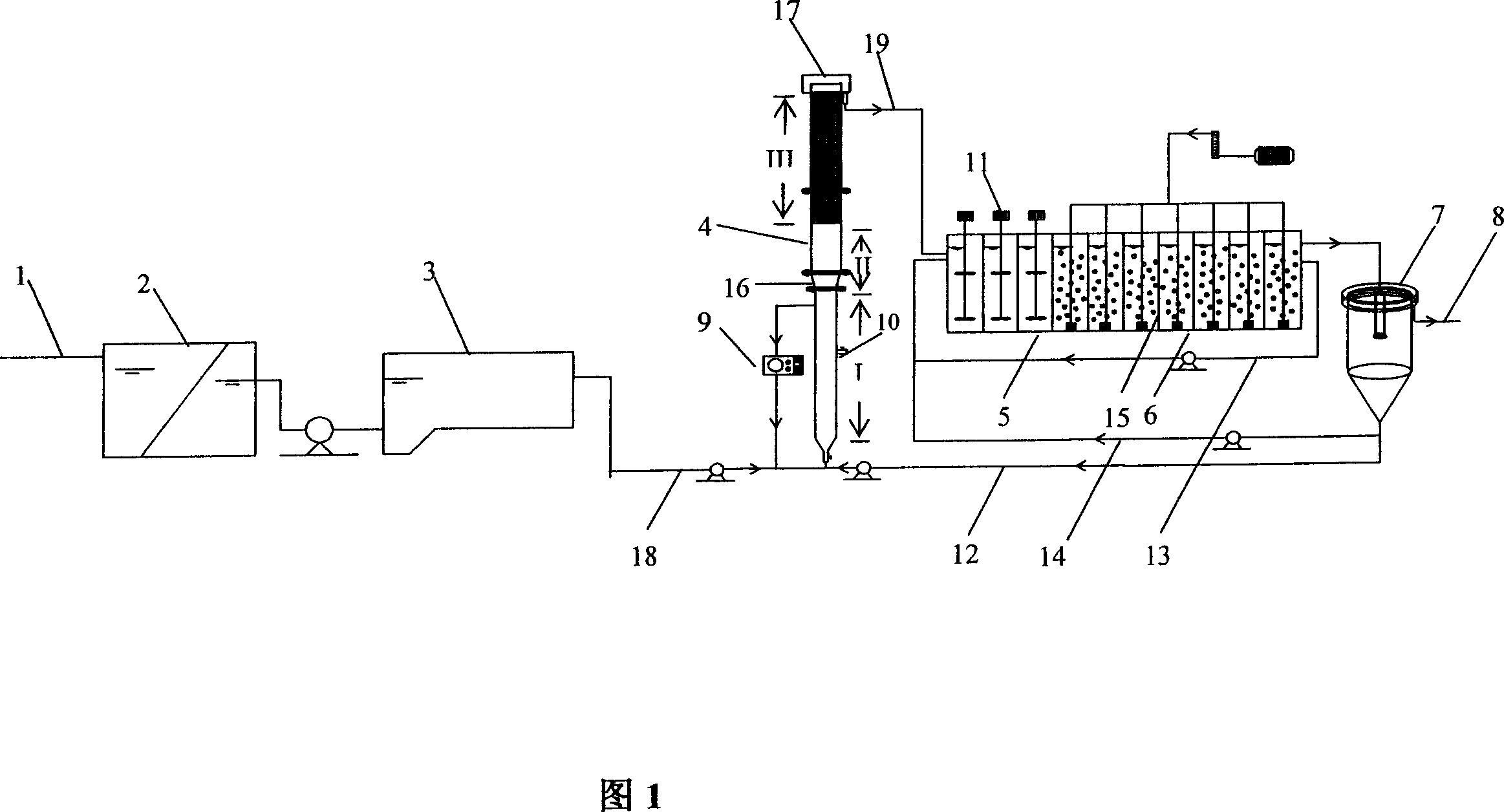

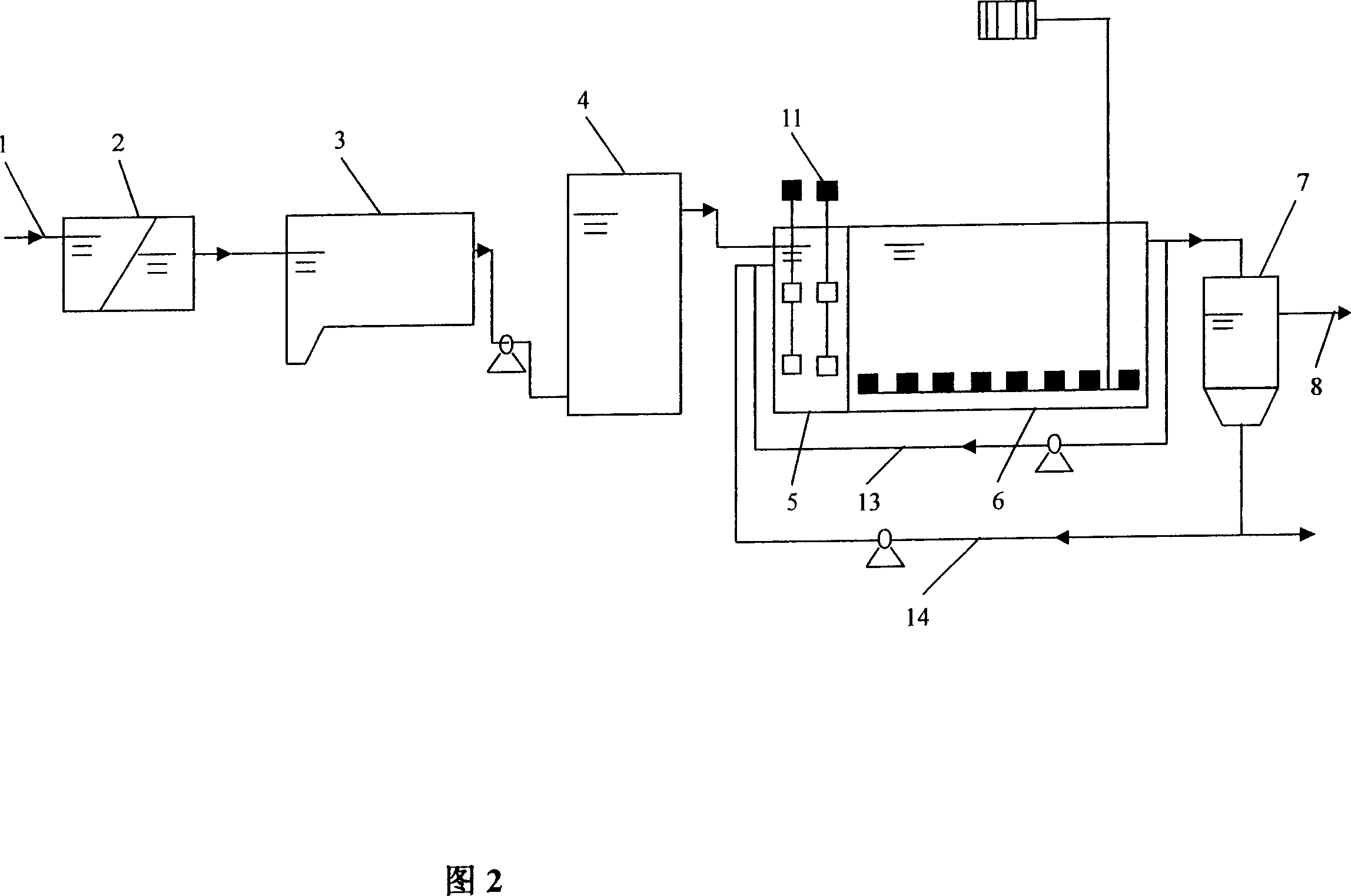

Method used

Image

Examples

experiment example 1

[0037] Experimental Example 1: Taking the actual domestic sewage discharged from a family area of a university as the raw water, the influent flow rate is 6L / h, the COD of the influent water=221~413mg / L, NH 4 -N=36~67mg / L. The experiments were carried out at room temperature (23-25°C). The running results show that: the experimental raw water BOD 5 / COD is 0.51, the BOD of hydrolysis acidification effluent 5 / COD increased to 0.74, and the biodegradability of sewage was greatly improved. System effluent NH 4 -N concentration below 2mg / L, NH 4 -The average removal rate of N exceeds 95%, the system effluent TN is less than 15mg / L, the average TN removal rate exceeds 74%, the system effluent COD is less than 30mg / L, the average COD removal rate exceeds 90%, and the apparent yield of sludge in the aerobic pool The coefficient is 0.23, which is 0.3-0.5 lower than that of the traditional sewage treatment process. After the sludge is hydrolyzed and acidified, the sludge volume...

experiment example 2

[0038] Experimental example 2: Taking the actual domestic sewage discharged from a family area of a university as the object, by adding beer and NH 4 Cl adjusts influent COD and NH 4 -N concentration. The influent flow rate is 8L / h, the COD and NH in the influent 4 -N, (COD=600~800mg / L, NH 4 -N=82~103 mg / L). The experiments were carried out at room temperature (23-25°C). The running results show that: the experimental raw water BOD 5 / COD is 0.43, the BOD of hydrolytic acidification effluent 5 / COD increased to 0.68, and the biodegradability of sewage was greatly improved. System effluent NH 4 -N concentration below 5mg / L, NH 4 -The average removal rate of N exceeds 93%, the system effluent TN is less than 30mg / L, the average TN removal rate exceeds 72%, the system effluent COD is less than 30mg / L, the average COD removal rate exceeds 95%, and the apparent yield of sludge in the aerobic pool The coefficient is 0.25, which is 0.3-0.5 lower than that of the traditiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com