Method for constituting conformal bearing microstrip antenna structure based on three dimension orthogonal machine woven fabric

A microstrip antenna and woven fabric technology, applied in the direction of antenna, radiating element structure, electrical components, etc., can solve the problems of structure delamination, antenna system failure, collapse, etc., and improve damage resistance and shape adaptability. Strong and complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Referring to Fig. 1, 2, the present invention constitutes the method for the conformal carrying microstrip antenna structure based on three-dimensional orthogonal woven fabric, mainly comprises the following steps:

[0032] (1) Select a fiber suitable as a three-dimensional composite material reinforcement, and weave it into a three-dimensional orthogonal fabric on a three-dimensional orthogonal loom;

[0033] (2) select a kind of resin to make the three-dimensional composite material by dipping the three-dimensional orthogonal woven fabric, test and calculate the dielectric constant and dielectric loss of the three-dimensional composite material;

[0034] (3) Utilize the dielectric constant of the obtained composite material to calculate the basic size of the microstrip antenna radiating element, and weave the basic structure prefabricated part of the microstrip antenna on the three-dimensional loom according to the size of the designed radiating element;

[0035] (4) ...

Embodiment 2

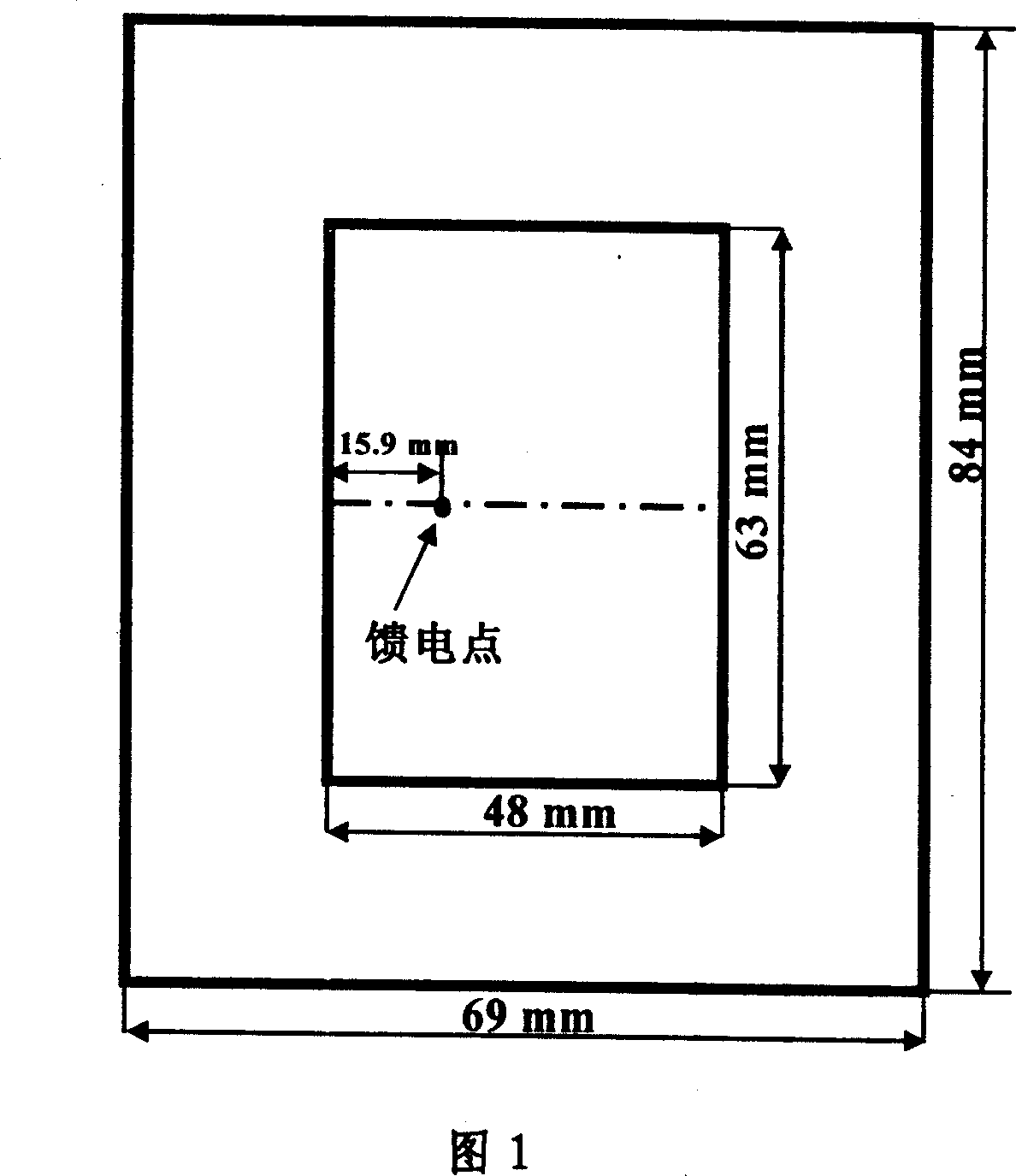

[0043] Refer to Figure 1, design the integrated structure of dipped antenna-three-dimensional composite material

[0044] 1. Select aramid fiber as the basic reinforcement of the composite material, choose Shanghai Fuchen Chemical 854 type bisphenol A epoxy vinyl resin as the resin, and use the transmission-reflection method to test and calculate the dielectric constant of the composite material to be 4;

[0045] 2. Design antenna radiating element size (dielectric constant is 4, substrate thickness is 4.5mm, resonant frequency is 1.5GHz) to calculate the antenna size parameters, as shown in Figure 1;

[0046] 3. Weaving prefabricated parts of 3D microstrip antenna

[0047] The three-dimensional fabric warp yarn is designed to be six layers, and the warp and weft yarns of the bottom layer are replaced by copper stranded wires, and the rest of the warp and weft yarns and the yarns in the Z direction are all aramid fibers. When weaving length along the warp direction reaches 10...

Embodiment 3

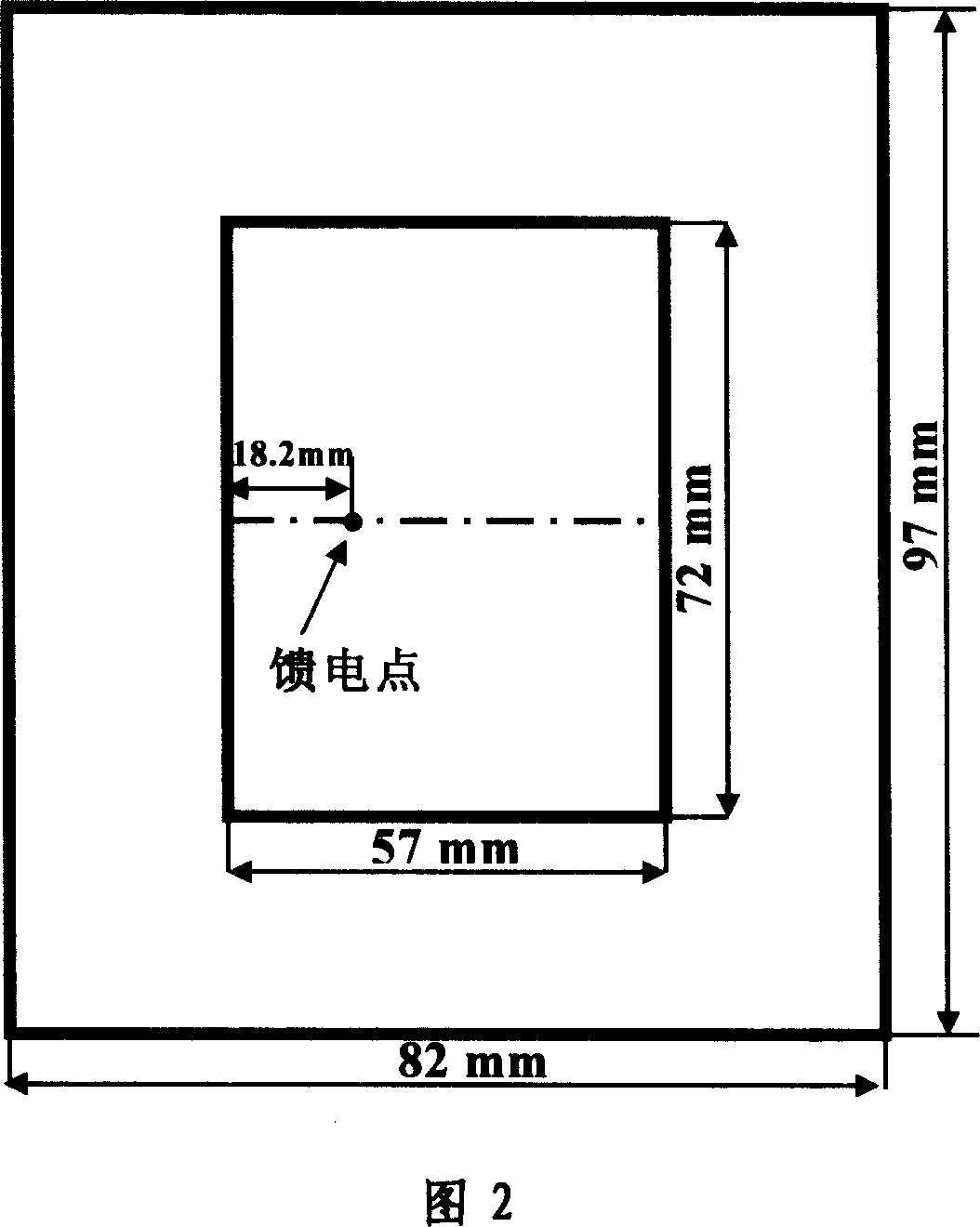

[0051] Refer to Figure 2, design the antenna-three-dimensional composite material integrated structure without dipping

[0052] (1) Design antenna radiating element size (dielectric constant is 2.8, substrate thickness is 4.5mm, resonant frequency is 1.5GHz)

[0053] (2) Weaving the prefabricated part of the three-dimensional microstrip antenna

[0054] The three-dimensional fabric warp yarn is designed to be six layers, and the warp and weft yarns of the bottom layer are replaced by copper stranded wires, and the rest of the warp and weft yarns and the yarns in the Z direction are all aramid fibers. When weaving length along the warp direction reaches 12.5mm, the first and second layers of warp yarns behind the three-dimensional loom are raised from the middle along the weft direction to a width of 57mm, and the yarns that have not been lifted in the two layers of yarns are combined by a layering device. Together, the yarn in the Z direction of the upper layer and the 57mm y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com