Lipid-lowering milk containing probiotics and its preparation method

A probiotics, fat milk technology, applied in the direction of milk preparations, dairy products, food preparation, etc., to achieve the effect of increasing high-density lipoprotein, lowering blood lipids, and stabilizing bacterial counts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the above-mentioned reduced-fat milk containing probiotics comprises the following steps:

[0057] (1) Disperse lecithin, sucrose ester, and molecularly distilled monoglyceride into low-fat or skimmed milk; when dispersing, use a water-powder mixer, but not limited to a water-powder mixer. Low-fat or skim milk should be between 50-90°C.

[0058] (2) Mix the low-fat or skimmed milk obtained in step (1) and homogenize; the homogenization temperature is 60-80°C; either first-level homogenization at 150-300bar is possible; or the pressure is successively 30-50bar and 100bar -250bar secondary homogenization.

[0059] (3) Sterilize the homogenized low-fat or skimmed milk in step (2); the sterilization condition is 65-140° C., and the time is 3 seconds to 30 minutes.

[0060] (4) Cool the low-fat or skimmed milk obtained after the sterilization in step (3) to 0-25°C.

[0061] (5) Disperse Lactobacillus plantarum powder with sterilized milk or steri...

Embodiment 1

[0067] Product formula (calculated per ton of final product):

[0068] raw material

Raw material requirements

Amount added

low fat milk

F=1.6%, P=3.1%, SNF=8.4%

996.00kg

1×10 11 cfu / g

1.00kg

Sucrose esters

1.00kg

Molecular Distilled Monoglyceride

2.00kg

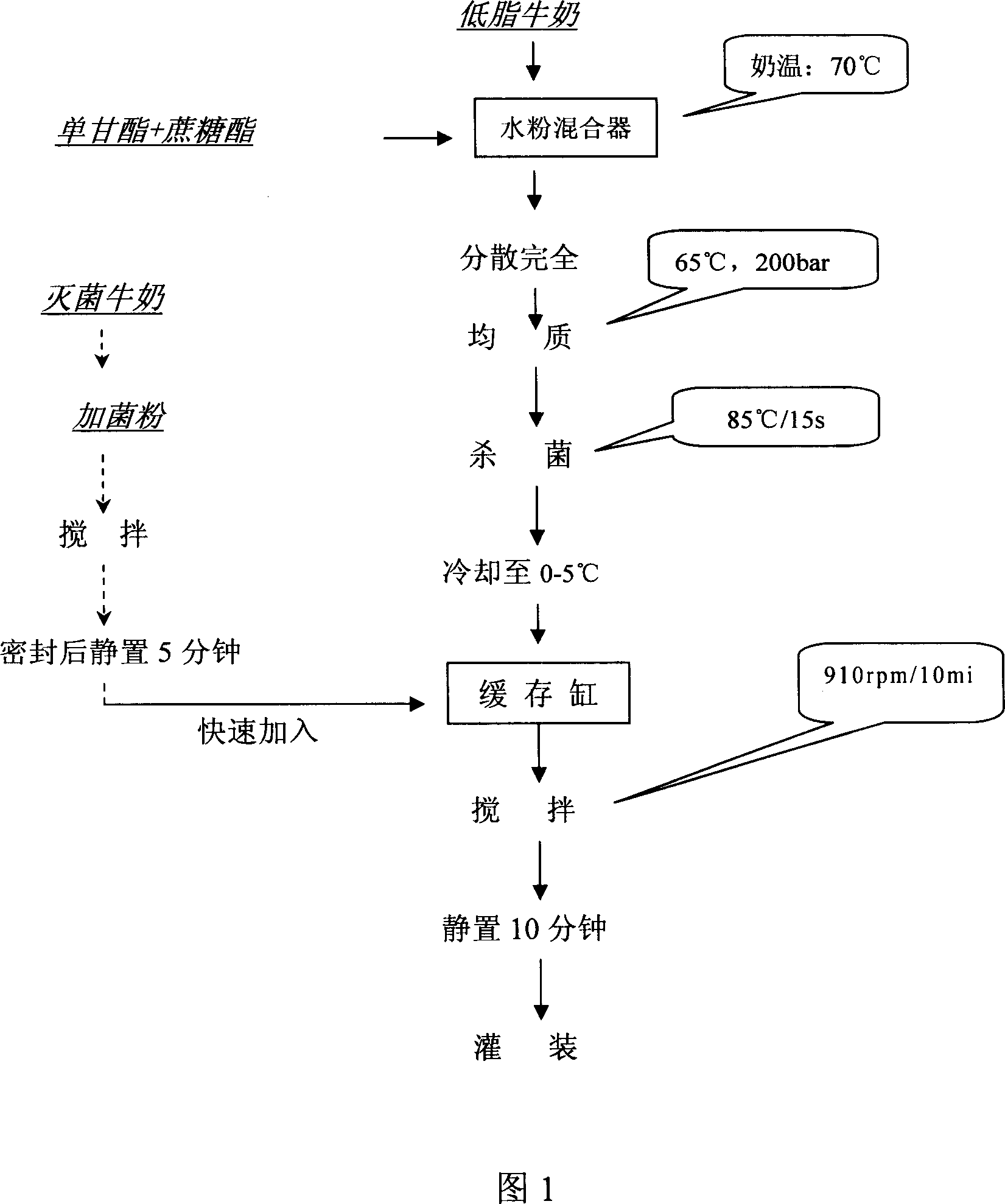

[0069] Its preparation method is referring to Fig. 1,

[0070] (1) Disperse sucrose esters and molecularly distilled monoglycerides into low-fat milk; when dispersing, use a water-powder mixer, but not limited to a water-powder mixer. The temperature of the milk is 70°C.

[0071] (2) The low-fat milk obtained in step (1) is mixed and homogenized; the homogenization temperature is 65° C.; and the first-level homogenization is performed at 200 bar.

[0072] (3) Sterilize the homogenized low-fat milk in step (2); the sterilization condition is 85° C., and the sterilization time is 15 seconds.

[0073...

Embodiment 2

[0081] Product formula (calculated per ton of final product):

[0082] raw material

Raw material requirements

Amount added

skim milk

F≤0.2%, P=4.0%, SNF=11.5%

989.00kg

Phosphatidylcholine content ≥ 35%

6.00kg

Lactobacillus plantarum

4.5×10 12 cfu / g

0.50kg

Sucrose esters

2.00kg

Molecular Distilled Monoglyceride

food grade

2.50kg

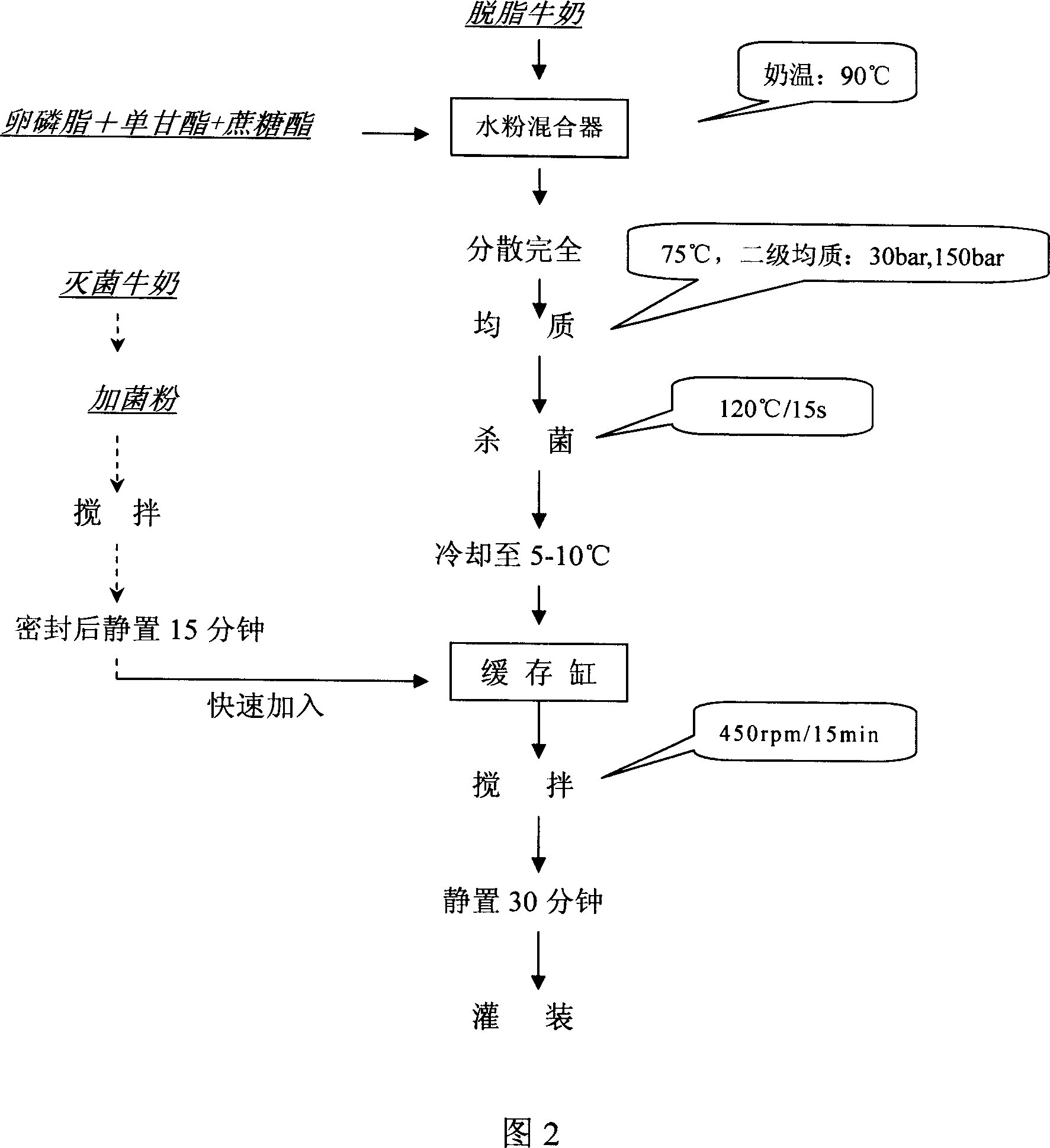

[0083] Its preparation method is referring to Fig. 2,

[0084] (1) Disperse lecithin, sucrose ester, and molecularly distilled monoglyceride into skim milk; when dispersing, use a water powder mixer, but not limited to a water powder mixer. The temperature of the milk is 90°C.

[0085] (2) The skim milk obtained in step (1) is mixed and homogenized; the homogenization temperature is 75° C.; and the pressure is successively two-stage homogenization of 30 bar and 150 bar.

[0086] (3) Sterilize the homogenized skim milk in step (2);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com