A fabric enhanced composite vascular prosthesis

A fabric-enhanced, artificial blood vessel technology, applied in the field of artificial blood vessels, can solve the problems of poor anti-thrombosis, excessive intimal hyperplasia, poor anti-permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

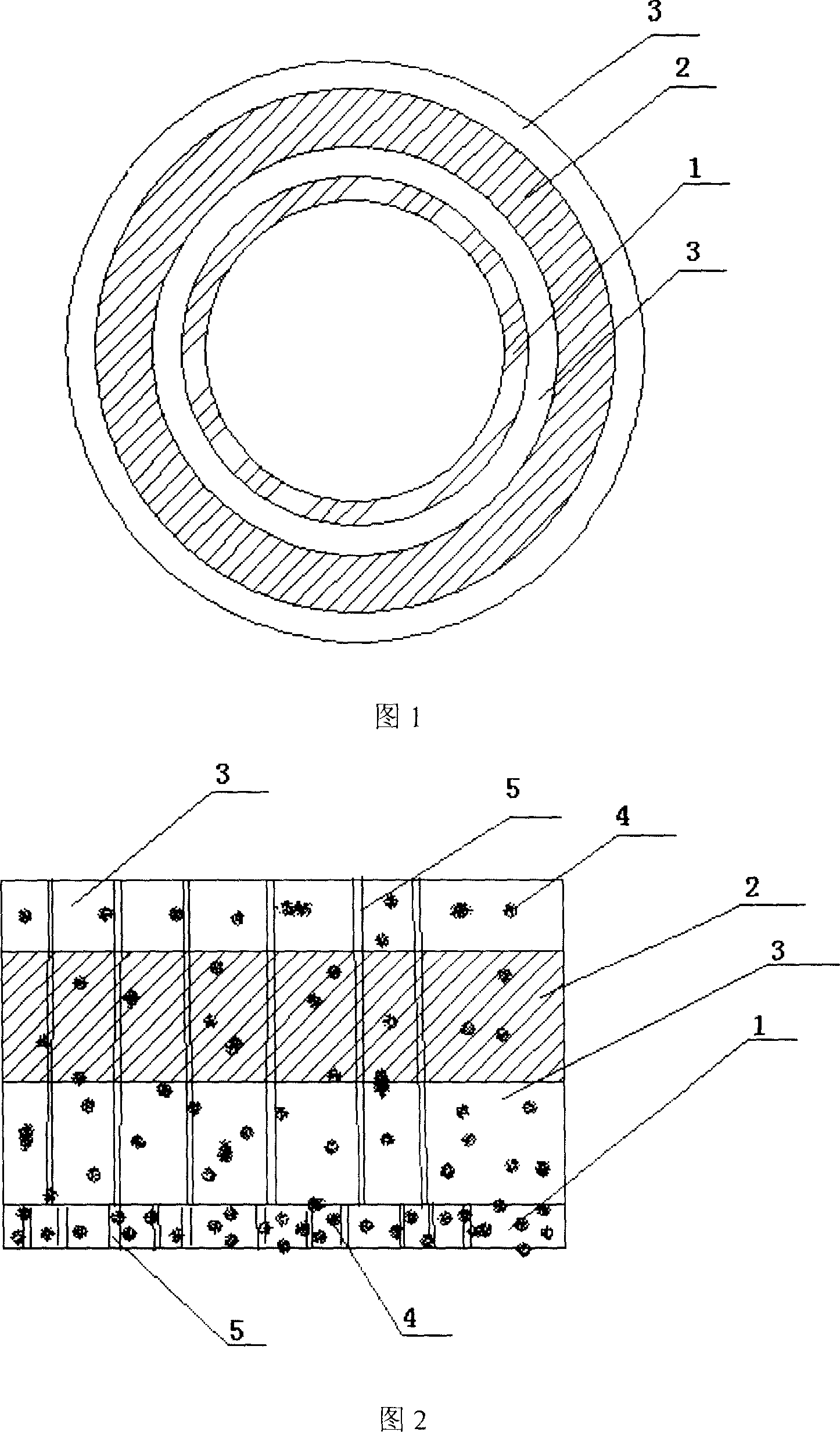

[0026] Embodiment 1: select polyester fabric as the fabric reinforcement layer, the blend of superfine silk powder and polyurethane as anticoagulant layer and elastic bonding layer, wherein the weight ratio of superfine silk powder and polyurethane in the anticoagulant layer is: 60:40, and the weight ratio of ultrafine protein powder and polyurethane in the elastic bonding layer is: 5:95.

[0027]First, the polyester staple fiber is processed into yarn on the spinning frame, and then processed into a tube fabric with a diameter of 4 mm on the warp knitting machine; the silk is processed into an ultrafine powder with a particle size of 2 microns; the polyurethane material is dissolved in DMF into a solution with a certain concentration, and the superfine silk powder is added to the polyurethane solution according to the weight ratio of silk ultrafine powder and polyurethane weight ratio of 60:40 and the weight ratio of silk ultrafine powder to polyurethane weight ratio of 5:95. ...

Embodiment 2

[0028] Embodiment 2: select silk fabric as the fabric reinforcement layer, the blend of superfine wool powder and polyurethane as anticoagulant layer and elastic bonding layer, wherein the weight ratio of superfine silk powder and polyurethane in the anticoagulant layer The formula is: 20:80, the weight ratio of ultrafine protein powder and polyurethane in the elastic bonding layer changes in a gradient.

[0029] Process the silk filaments on the loom into tubular fabrics with a diameter of 5 mm; process the wool into ultrafine powders with a particle size of 10 microns and 1 micron; dissolve the polyurethane material into a solution of a certain concentration with DMF, press Wool superfine powder and polyurethane weight ratio of 20:80 Add wool superfine powder with a particle size of 10 microns to the polyurethane solution, according to the wool superfine powder and polyurethane weight ratio of 5:95, 8:92, 10 : 90, 20: 80, the wool superfine powder with a particle size of 1 m...

Embodiment 3

[0030] Embodiment 3: Select spandex fabric as the fabric reinforcement layer, and polyurethane as the anticoagulant layer and elastic bonding layer.

[0031] Spandex filaments are processed on a loom into tubular fabrics with a diameter of 5 mm; the polyurethane material is dissolved into a solution of a certain concentration with DMF. First, a mold with a diameter of 5 mm is immersed in the polyurethane solution, and an anticoagulant layer is formed on the surface of the mold after drying; then a tube fabric with a diameter of 5 mm is placed on the surface of the same mold, and then repeatedly immersed in the polyurethane solution. After drying, it can be made into the initial artificial blood vessel shape, and then processed into the final artificial blood vessel after post-processing such as microporation and sulfonation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com