Process for preparing rutile phase spherical nano TiO2

A nano-titanium dioxide, rutile phase technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high preparation cost, application limitation, complex process, etc., and achieve the effect of simple preparation process, simplified preparation process and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

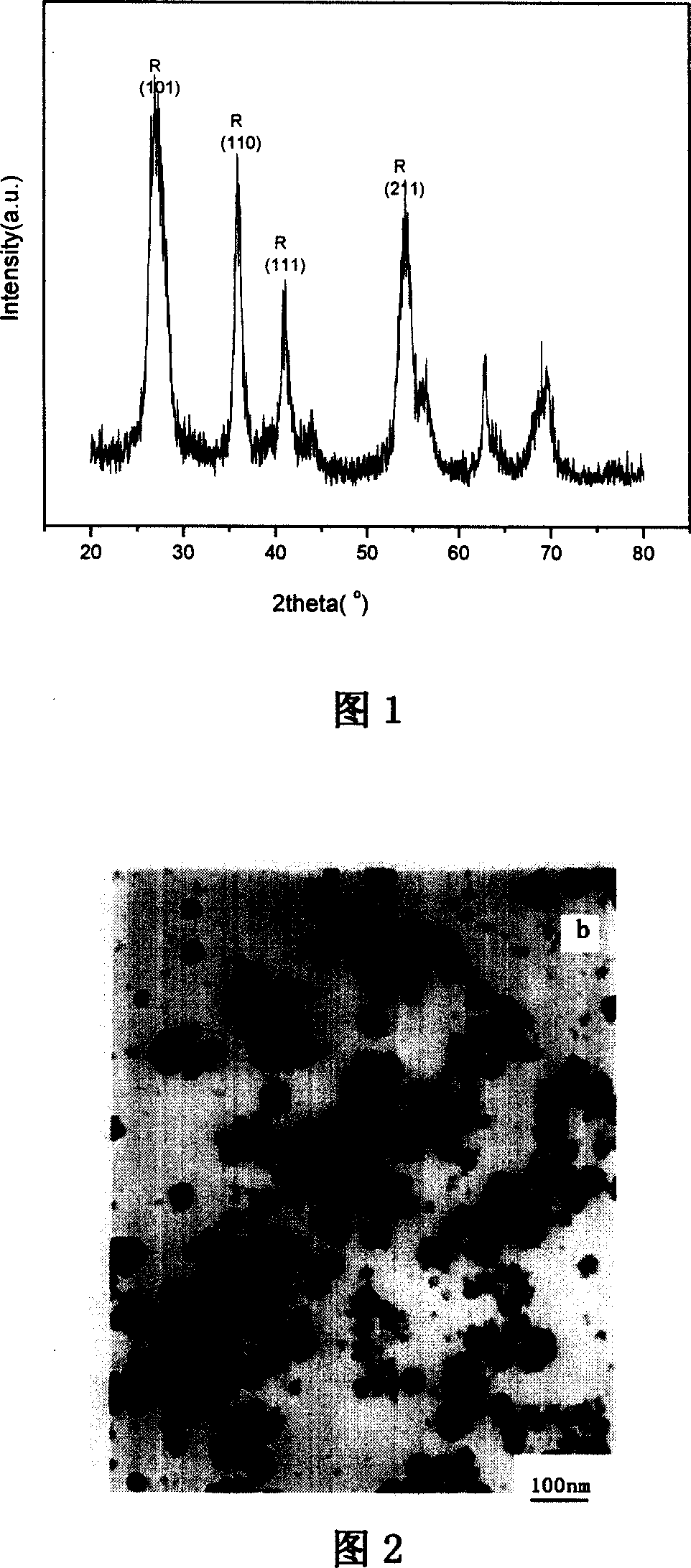

[0013] Add 5.5mL TiCl to the reactor 4 , Distilled water 95.5mL, TiCl 4 The concentration is 0.5 mol / L, a condensing device is installed on the reaction kettle, the temperature is raised to 100°C, and the temperature rise rate at which the reactant is heated to boiling is 5°C / min. The reaction was continued for 5 hours. After the reaction, it was cooled to room temperature, filtered, washed with distilled water several times, and dried at 80°C for 12 hours. The obtained powder was calcined at 200°C for 5 hours to obtain 3.9g of product. X-ray diffraction results show that the powder is rutile phase, no anatase diffraction peak appears (as shown in Figure 1), and the particle size of the powder is 25 nm (as shown in Figure 2).

Embodiment 2

[0015] Add 8.8mL TiCl to the reactor 4 , Distilled water 91mL, TiCl 4 The concentration is 0.8 mol / L, a condensing device is installed on the reaction kettle, the temperature is raised to 80°C, and the heating rate of the reactant is heated to boiling at 2.5°C / min. The reaction was continued for 5 hours. After the reaction, it was cooled to room temperature. After filtration, it was washed several times with distilled water, dried at 60°C for 24 hours, and the obtained powder was calcined at 600°C for 2 hours to obtain 6.3 g of product. X-ray diffraction results show that the powder is rutile, no anatase diffraction peak appears, and the particle size of the powder is 70 nm.

Embodiment 3

[0017] Add 11ml TiCl to the reactor 4 , Distilled water 89mL, TiCl 4 The concentration is 1.0 mol / L, a condensing device is installed on the reaction kettle, the temperature is raised to 100°C, and the temperature rise rate of the reactant heated to boiling is 3.5°C / min. The reaction was continued for 5 hours. After the reaction, the temperature was lowered to room temperature. After filtration, it was washed several times with distilled water and dried at 80°C for 12 hours. The obtained powder was calcined at 600°C for 3 hours to obtain 7.8 g of product. X-ray diffraction results show that the powder is rutile, no anatase diffraction peak appears, and the particle size of the powder is 90nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com