Amphiprotic high polymer loaded phosphine compound and its preparation method

A technology of amphoteric polymers and phosphine compounds, applied in chemical instruments and methods, isomerization hydrocarbon production, organic compound/hydride/coordination complex catalysts, etc., to achieve sufficient catalytic effect, cheap and easy-to-obtain raw materials, and good industrialization foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

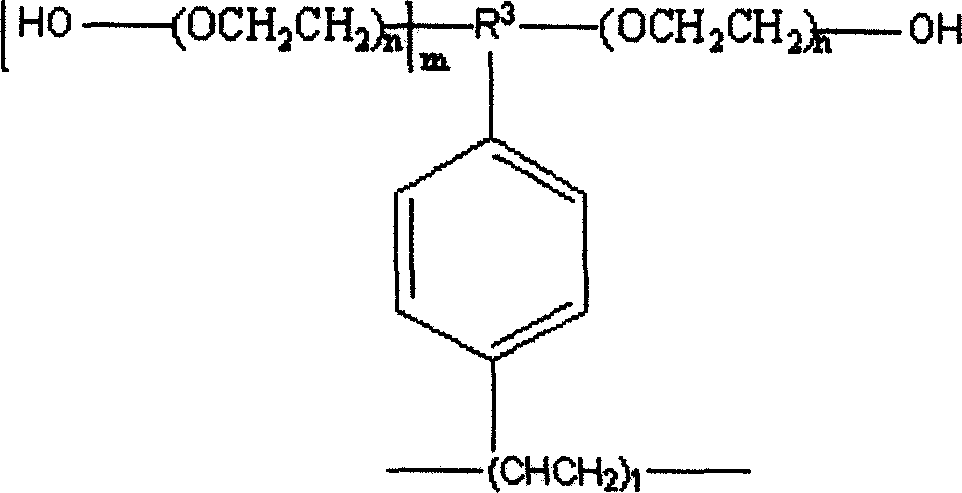

Image

Examples

Embodiment 1

[0022] Step 1: Add 1.2 g, 50 mmol sodium metal to anhydrous toluene, heat to reflux, slowly cool, add 24 g, 60 mmol polyethylene glycol (molecular weight is 400), stir and react at 60 ° C until there is no metal sodium, and then Add 4 grams of chloromethylated polystyrene (PS-CH 2 Cl) Resin (chlorine content is 18%), stirred and reacted below 60° C. for 9 hours. After the reaction is completed, wash and filter with water and ethanol, extract with tetrahydrofuran, and dry below 70°C to obtain a polystyrene-polyethylene glycol copolymer resin (quantitative). The chlorine content is 1.5% as measured by the combustion method.

[0023] Step 2: Add 4 g, 2.3 mmol of the product of step 1 to 50 ml of pyridine, slowly add 0.44 g, 2.3 mmol of p-toluenesulfonyl chloride at 20°C, stir for 1 day, filter, extract with tetrahydrofuran, and dry to obtain p-toluene The polyethylene glycol-polystyrene copolymer resin (quantitative) in which the sulfoester group has substituted the hydroxyl gro...

Embodiment 2

[0026] Step 1: Add 0.6 g, 25 mmol of sodium metal to anhydrous toluene, heat to reflux, slowly cool, add 150 g, 30 mmol of polyethylene glycol (molecular weight is 5000), and stir at 100 ° C until there is no metal sodium, and then Add 4 grams of chloromethylated polystyrene (PS-CH 2 Cl) Resin (chlorine content 20%), stirred and reacted below 100°C for 1 day. After the reaction is completed, wash and filter with water and ethanol, extract with tetrahydrofuran, and dry below 70°C to obtain a polystyrene-polyethylene glycol copolymer resin (quantitative). The chlorine content is 0.5% as measured by the combustion method.

[0027] Step 2: Add 4 grams, 0.5 mmol of the product of step 1 to pyridine, slowly add 1 gram, 5 mmol of p-toluenesulfonyl chloride at 0°C, stir and react for 10 days, filter, extract with tetrahydrofuran, and dry to obtain product 2 (quantitative ), the sulfur content recorded by elemental analysis is 1.06%.

[0028] Step 3: In anhydrous toluene dissolved wi...

Embodiment 3

[0030] Step 1: Add "ArgoGel"-OH (3 g, 1.3 mmol) to pyridine, slowly add 1.3 g, 7 mmol p-toluenesulfonyl chloride at 10°C, stir for 3 days, filter, extract with tetrahydrofuran, and dry to obtain "ArgoGel" (quantitative) with p-toluenesulfonyl ester group, the sulfur content was 4.3% as measured by elemental analysis.

[0031]Step 2: In anhydrous toluene dissolved with 0.9 g, 5.3 mmol of butylphenylphosphine lithium, 2.4 g, 1 mmol of the product of step 1 was added, stirred and reacted for 3 days, filtered, extracted with tetrahydrofuran, dried to obtain the target product, The elemental analysis shows that the phosphorus content is 4.0%, and the sulfur content is 0%, indicating that dibutylphosphine has been successfully loaded on the polystyrene-polyethylene glycol copolymer resin, and the molecular weight is about 2500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com