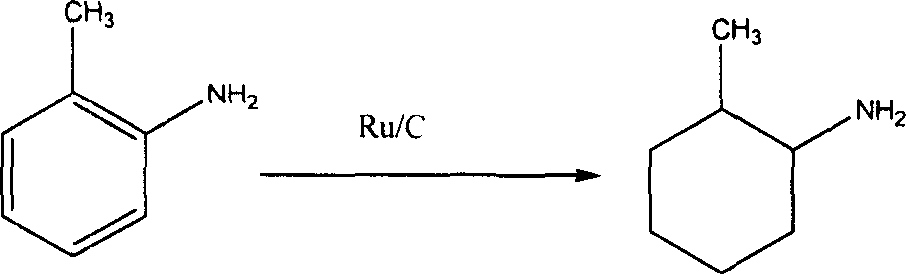

Method of preparing o-methylcyclohexylamine

A technology of o-methylcyclohexylamine and o-toluidine, applied in the field of preparation of o-methylcyclohexylamine, can solve the problem that there is no o-methylcyclohexylamine industrial production technology, no o-methylcyclohexylamine, no suitable Industrial production and other problems, to achieve the effect of easy industrial promotion and application, good product quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 3Kg o-toluidine (2-methylcyclohexylamine), 100g Ru content is 3% Ru / C catalyst (ruthenium charcoal catalyst), 30L ethanol are made solvent in the autoclave of 50L band stirrer, to high pressure reaction The interlayer of the autoclave was heated with steam to raise the temperature. The autoclave was first replaced with nitrogen three times, and then replaced with hydrogen three times. The stirring was started, and the catalytic hydrogenation reduction reaction was carried out under the conditions of T=100-120°C and P=3Mpa. After the hydrogenation reaction is finished, cool to room temperature, filter, and separate the Ru / C catalyst. The separated Ru / C catalyst is washed with solvent ethanol and recycled. The filtrate after the separated Ru / C catalyst is pumped into a 50L still. Atmospheric distillation is first carried out, and the preceding fraction (solvent ethanol) is collected, and the ethanol recovered can be used as the next batch of solvents to continue to apply m...

Embodiment 2

[0022] Other conditions are the same as in Example 1, except that the Ru / C catalyst adopts a Ru / C catalyst with a Ru content of 5%. 2.28 kg of the product (o-methylcyclohexylamine) was obtained, the mass yield was 76%, and the content (tran+cis): ≥99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com