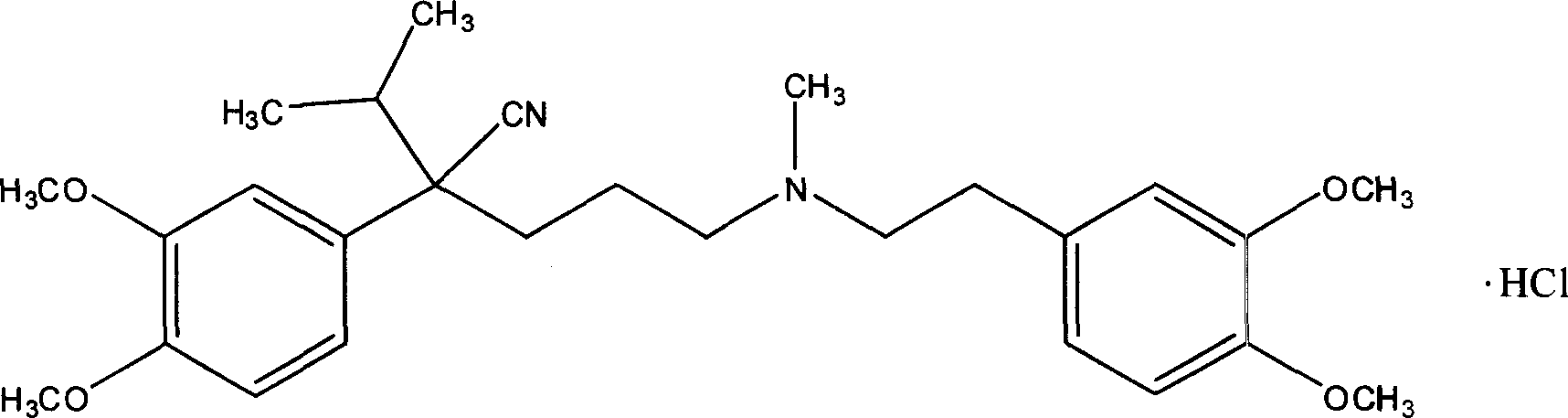

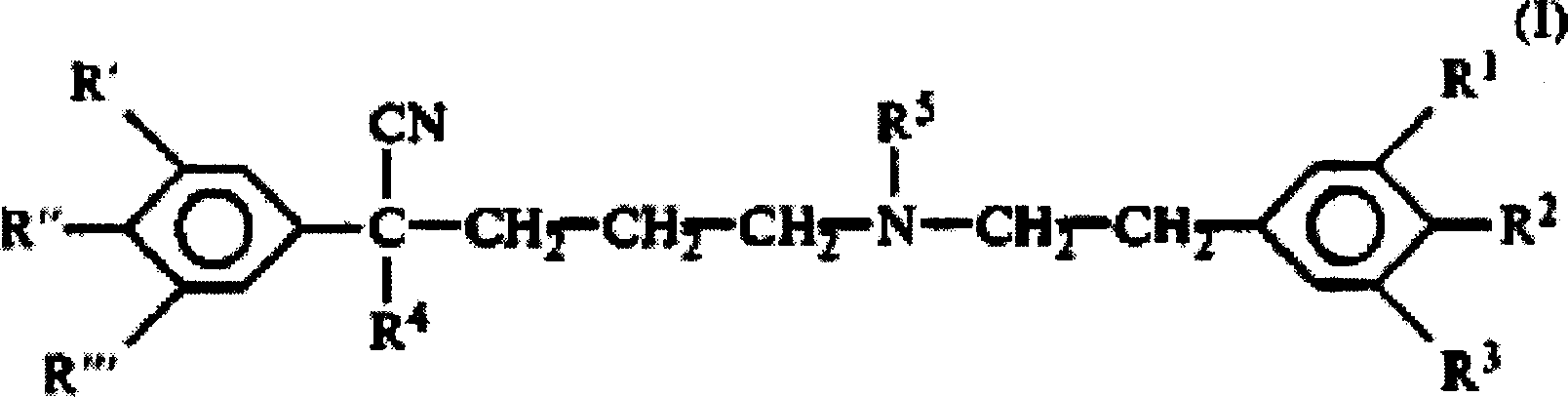

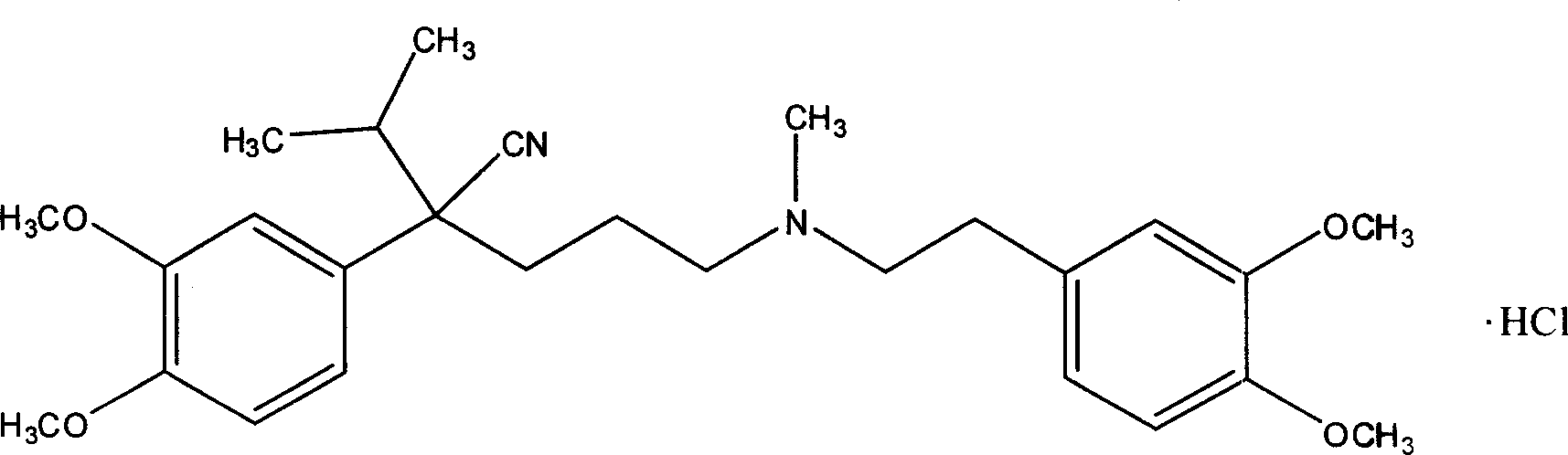

Method of refining verapamil hydrochloride

A technology of verapamil hydrochloride and its refining method, which is applied in the direction of purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of increasing production cost, etc., and achieve the effect of simple industrial operation and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The verapamil hydrochloride of 25 grams (HPLC is 96.5%) is added in the 250 milliliter round-bottomed reaction flasks that stirring and reflux condenser are equipped with, add 175 milliliters of acetone and 5 milliliters of water, after reflux is made to dissolve, add 1.2 grams of activated carbon, filtered, cooled to 15°C with stirring to precipitate crystals. Filtration, rinsing with acetone, and drying at 100°C gave 19.7 g of the product. HPLC showed that the purity was greater than 99.5% (area normalization method), and the melting point was 141.5-145°C.

Embodiment 2

[0050] The verapamil hydrochloride of 25 grams (HPLC is 96.5%) is added in the 250 milliliter round-bottom reaction flasks that stirring and reflux condenser are equipped with, add 125 milliliters of isopropanols and 5 milliliters of water, after reflux is made to dissolve, Add 1.2 g of activated carbon, filter, and cool to 15°C with stirring to precipitate crystals. Filtration, rinsing with isopropanol, and drying at 100°C yielded 21.2 g of the product. HPLC showed a purity greater than 99.5% (area normalization method), and a melting point of 141.5-145°C.

Embodiment 3

[0052] The verapamil hydrochloride of 50 kilograms (HPLC is 96.5%) is added in the reactor of 500 liters that stirring and reflux condenser are equipped with, add 350 liters of acetone and 5 liters of water, after heating and refluxing to make it dissolve, add 1.2 kilograms of gacs , filtered, and cooled to 15°C with stirring to precipitate crystals. Filter, wash with acetone, and dry at 100°C to obtain 44.5 kg of the product. HPLC shows that the purity is greater than 99.5% (area normalization method), and the melting point is 141.5-145°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com