Preparing method for mesoporous silicon dioxide material

A mesoporous silica and mesoporous structure technology, applied in the direction of silica, silicon oxide, etc., to achieve the effect of reducing production costs and reducing corrosion of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

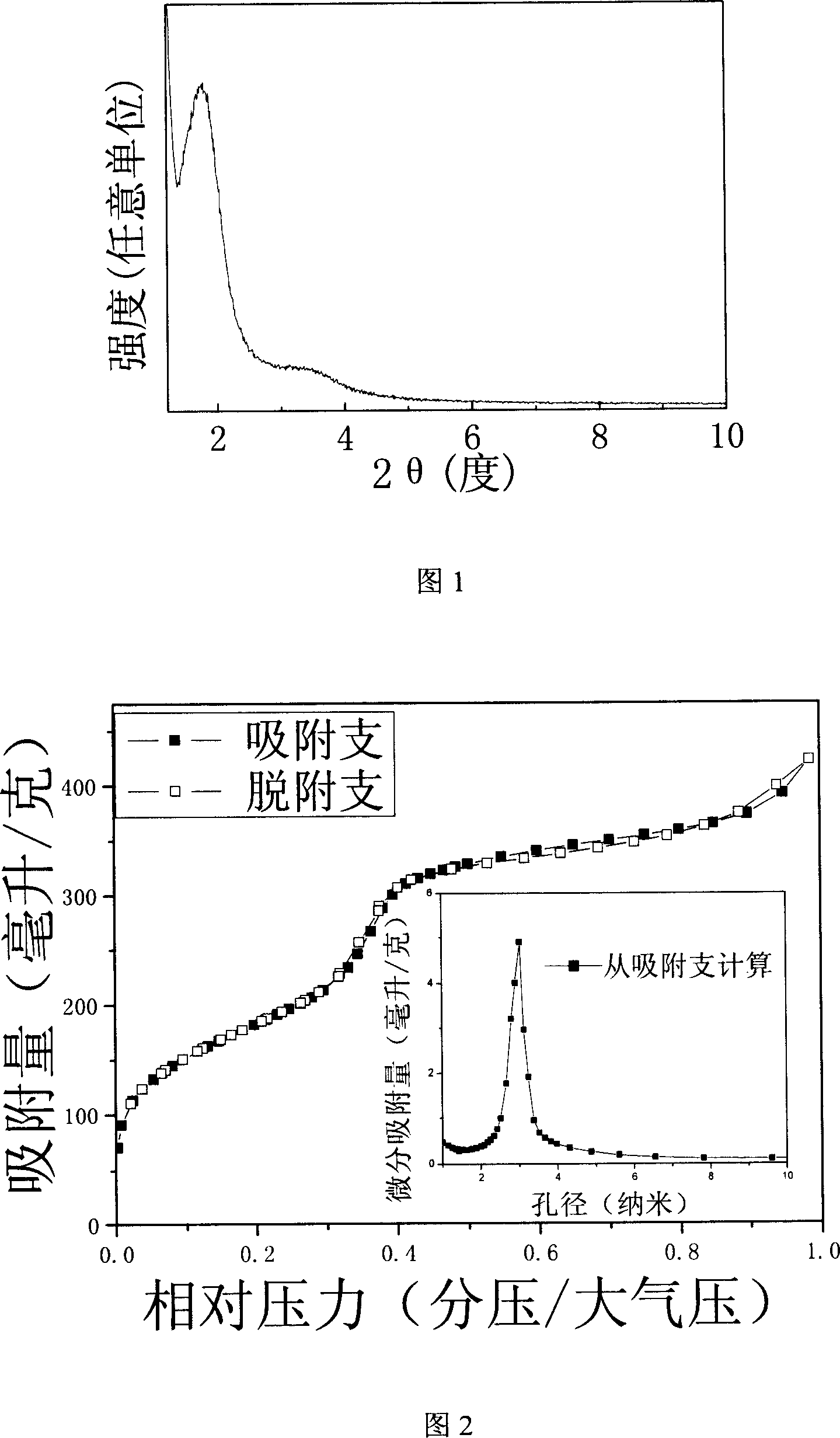

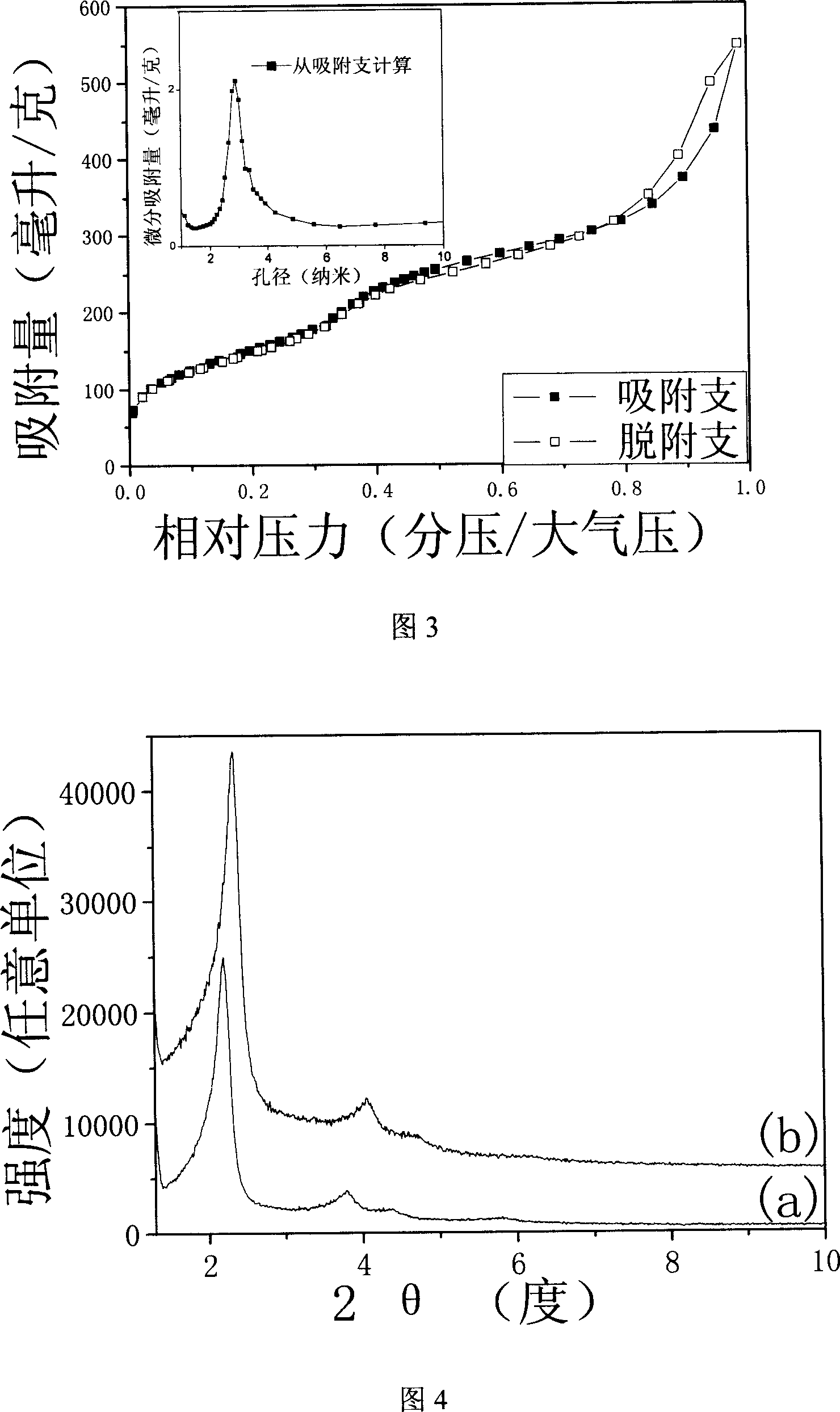

[0024] According to the ratio: 0.2CTAB: 1TEOS: 0.5NaNO 3 : 100H 2 O Add 7.3 g of CTAB, 180 mL of deionized water and 4.25 g of NaNO to the reactor in sequence 3 , stirred until completely dissolved into a transparent solution, at this time the viscosity of the solution is very high. 20.8 g of TEOS was added to the solution, pH = 6, left to react at room temperature for 6 days, and a white mixture was obtained. Filter, wash and dry to obtain a white product. After the product is dried, it is baked at 540°C for 6 hours to remove the templating agent. The XRD pattern of the sample after calcination is shown in Figure 1, and Figure 1 is the powder X-ray diffraction pattern (XRD) of Example 1, which is consistent with the reported mesoporous materials with wormholes. The d value of the mesoporous structure was calculated to be 4.93 nm. The nitrogen adsorption isotherm and the pore size distribution of the sample after roasting are shown in Fig. 2, and Fig. 2 is the nitrogen ad...

Embodiment 2

[0026] According to the ratio: 0.2CTAB: 1TEOS: 0.15NaNO 3 : 100H 2 O 7.3 g of CTAB, 180 mL of deionized water and 1.27 g of NaNO were sequentially added to the reactor 3 , stirred until completely dissolved into a viscous transparent solution. 20.8 g of TEOS was added to this solution, pH = 6, stirred at room temperature for 6 days, and a white mixture was obtained. Filter, wash and dry to obtain a white product. The nitrogen adsorption isotherm and pore size distribution of the product after roasting are shown in Figure 3. The most visible pore size is 3.0nm, and the specific surface area is 541m 2 / g.

Embodiment 3

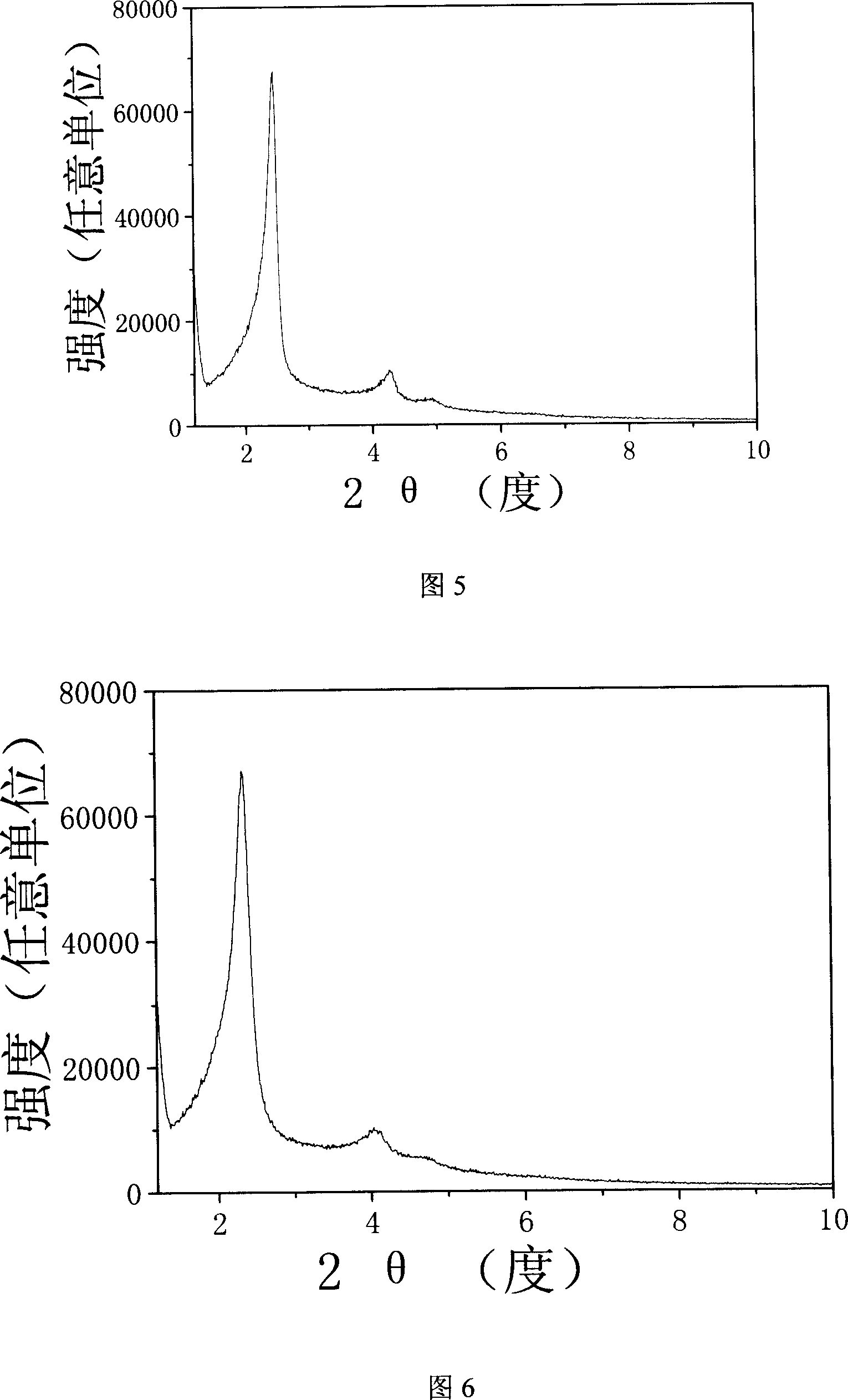

[0028] According to the ratio: 0.2CTAB: 1TEOS: 0.5Al(NO 3 ) 3 : 100H 2 O sequentially add 7.3g CTAB, 180mL deionized water and 18.8g Al(NO 3 ) 3 , stirred until completely dissolved into a transparent solution, at this time the viscosity of the solution is very high. 20.8 g of TEOS was added to this solution, and the reaction was allowed to stand at room temperature for 3 days to obtain a white mixture. Filter, wash and dry to obtain a white product. The XRD pattern of the product before and after firing is shown in Figure 4, (a) is the XRD pattern of the unroasted product, and (b) is the XRD pattern of the fired product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com