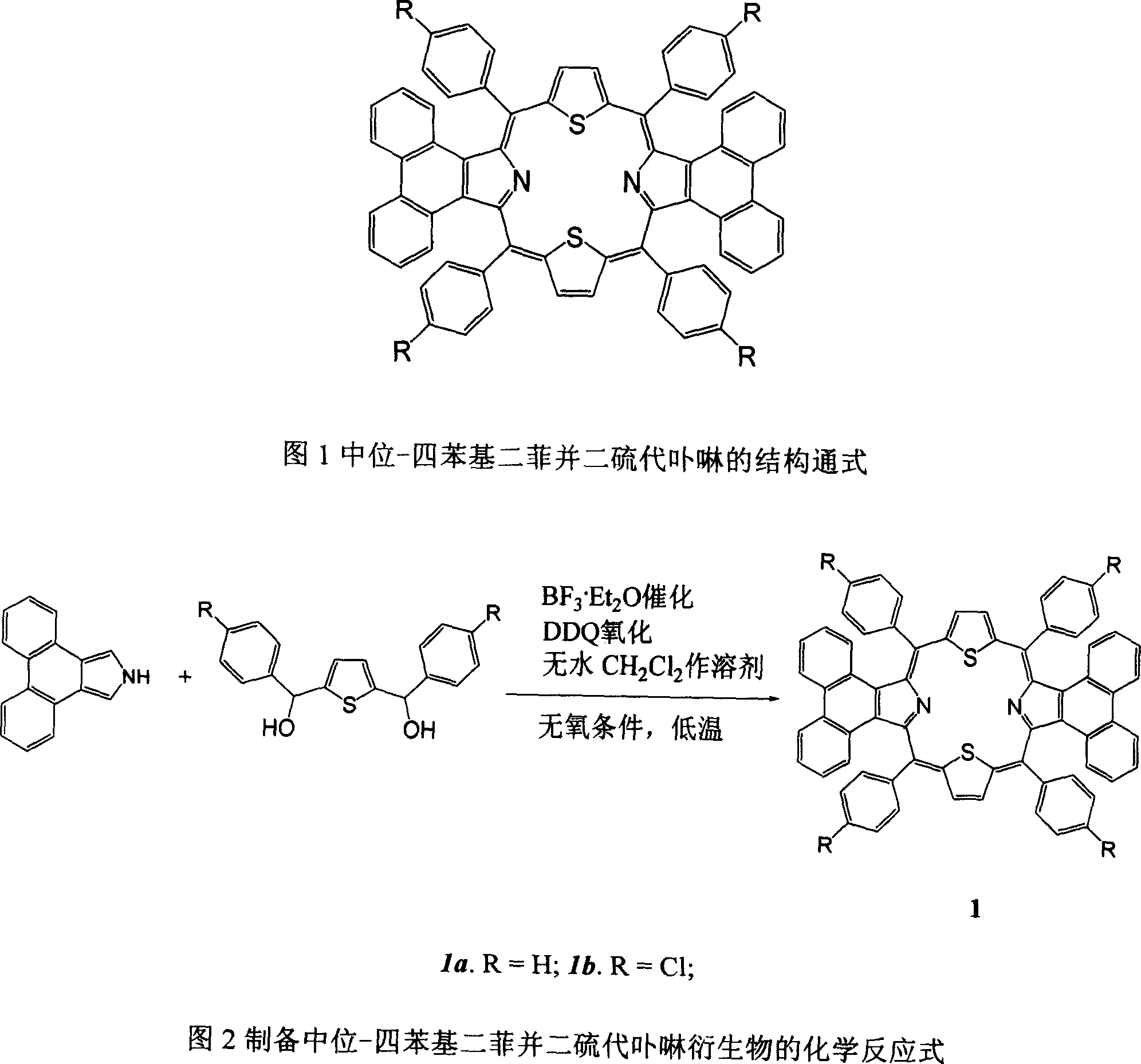

Synthesis of middle position-tetraphenyldiphenanthrene disulphoporphyrin derivative and application thereof

A technology of tetraphenyldiphenanthrenedithioporphyrin and phenanthrenepyrrole, which is applied in the synthesis and application fields of meso-tetraphenyldiphenanthrenedithioporphyrin derivatives, and can solve the problem of many by-products. , difficult purification, low yield and other problems, to achieve the effect of improving conversion efficiency and absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

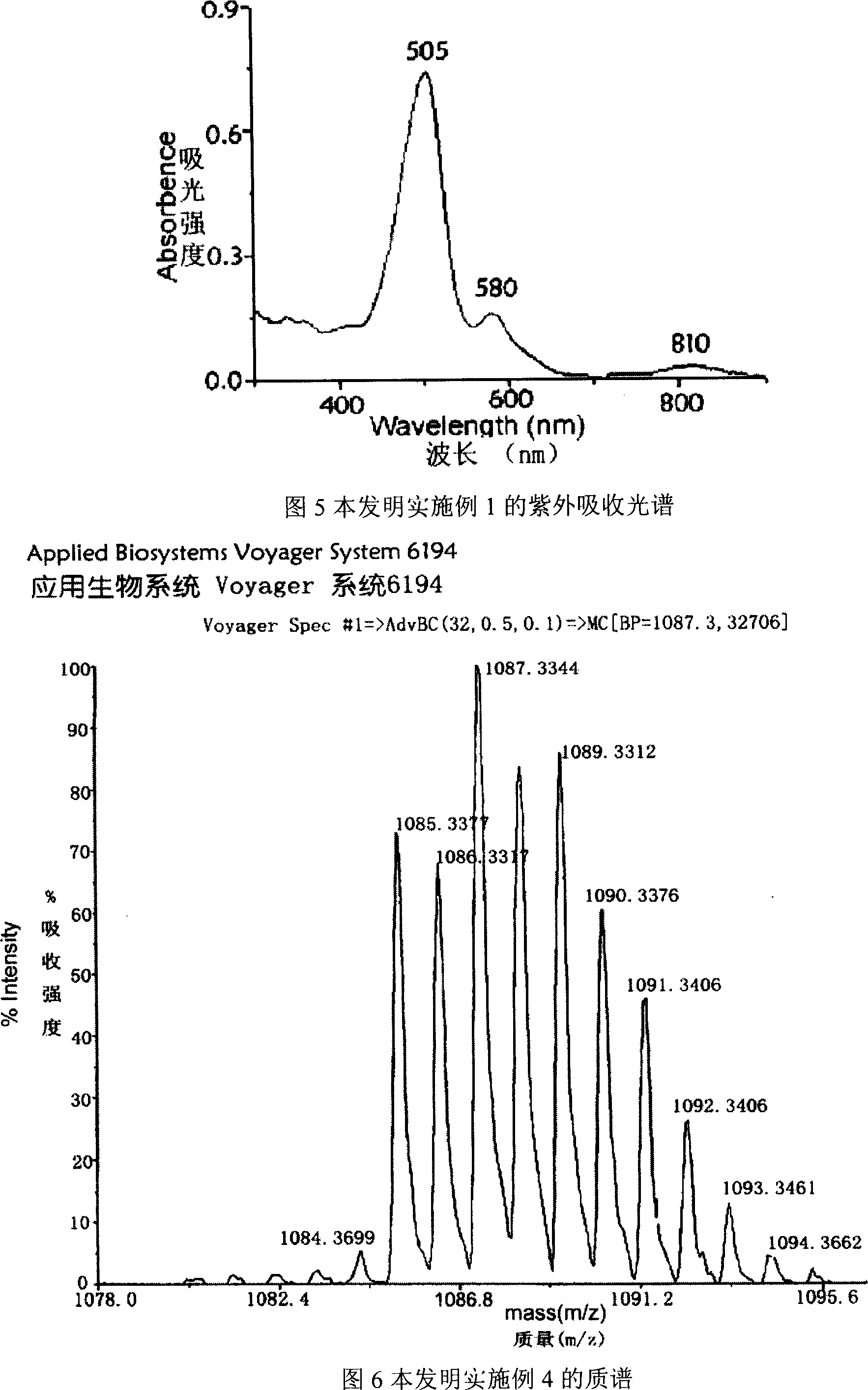

Examples

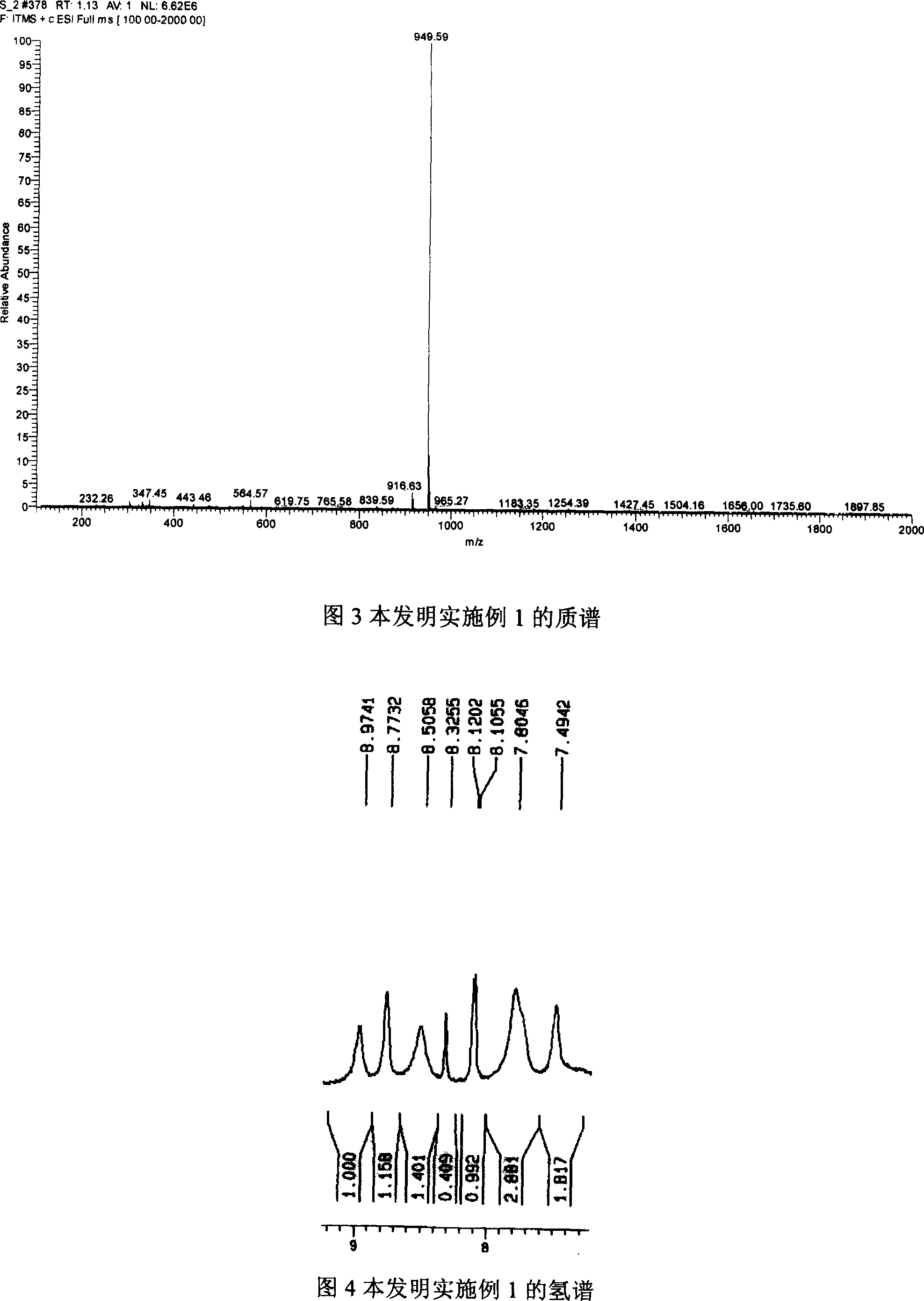

Embodiment 1

[0021] Embodiment 1: 5,10,15,20-tetraphenyl-diphenanthrene[9,10-b:9,10-l]-22,24-dithioporphyrin (1a) synthesis in 250ml circle Add 1mmol (278mg) 2,5-bis(phenylhydroxymethyl)thiophene, 1mmol (217mg) phenanthropyrrole and 60ml of anhydrous dichloromethane into the bottom flask, put a magnet and start stirring, and react under the protection of argon. Put the bottle in a cryogenic device and keep it away from light, control the reaction temperature at -30±10°C, add a total of 0.17ml of BF 3 ·Et 2 O, after making it react at low temperature for 2 hours, allow it to naturally warm up to room temperature and continue the reaction for 48 hours. 1 mmol DDQ (227 mg) was added to the reaction solution, and reacted for 1 hour. The solvent was distilled off under reduced pressure for chromatographic separation, and purple-black crystals were obtained after recrystallization from methanol and chloroform. Yield: 15%; Melting point: >250°C; ESI MASS: calcd for C 68 h 40 N 2 S 2 949.2...

Embodiment 2

[0022] Embodiment 2: The synthetic preparation method of 5,10,15,20-tetraphenyl-diphenanthrene[9,10-b:9,10-l]-22,24-dithioporphyrin (1a) is the same as In Example 1, only 1.25 mmol of 2,5-bis(phenylhydroxyl)methylthiophene was added. Yield: 10%.

Embodiment 3

[0023] Embodiment 3: the synthesis of 5,10,15,20-tetraphenyltetraphenanthrene porphyrin (1a)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com