Bacillus subtilis capable of producing high purity 3-hydroxy butanone

A technology of Bacillus subtilis and hydroxybutanone, which is applied in the field of Bacillus subtilis strains and Bacillus subtilis, can solve the problems that the 3-hydroxybutanone process has not been widely used, difficulties, raw material sources, prices and application restrictions of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 Breeding of Bacillus subtilis producing 3-hydroxybutanone

[0060] The starting strain SFA-W15 (a strain of Bacillus subtilis that accumulates a small amount of 3-hydroxybutanone) was inoculated into a liquid seed medium, cultivated at 37°C to the mid-log phase, centrifuged to collect the bacteria, and washed with sterile saline. Times, and then add sterile saline to make a bacterial suspension so that the cell concentration is 1×10 8 -10 9 Pcs / ml.

[0061] Take 10ml of the above bacterial suspension and put it in a petri dish, place it under a 30W ultraviolet lamp, and irradiate it with an irradiation distance of 15cm. The irradiation time is 3 minutes, 5 minutes, 7 minutes, and 10 minutes. The interval sampling is appropriately diluted and coated with 0.5% LiCl. Plate, protected from light at 37°C for 1-2 days, pick a single colony to transfer to the inclined plane, culture at 37°C for 1-2 days, inoculate a shake flask containing fermentation medium after the in...

Embodiment 2

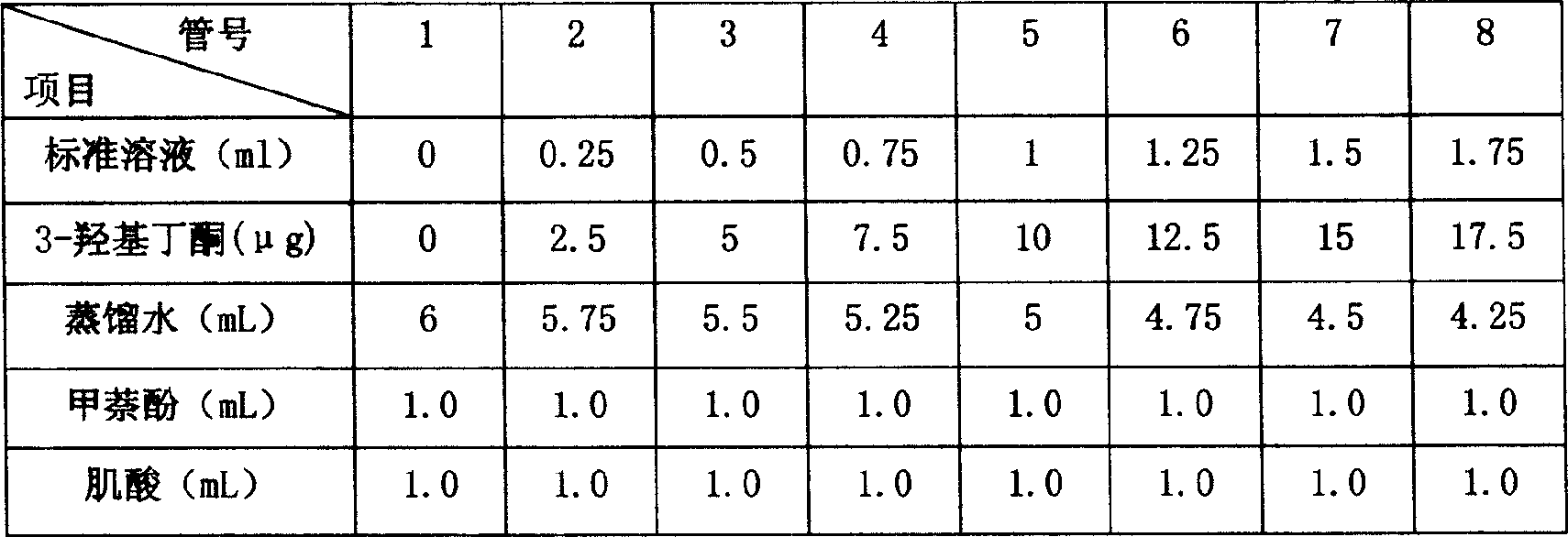

[0064] Example 2 Breeding of Bacillus subtilis CGMCC NO.1869 strain producing high-purity 3-hydroxybutanone

[0065] The mutant strain SFA-U97 screened in Example 1 was inoculated into liquid seed culture medium, cultivated at 37°C to the mid-log phase, centrifuged to collect the bacteria, washed twice with sterile saline, and then added with sterile saline Make a bacterial suspension so that the cell concentration is 1×10 8 -10 9 Pcs / ml, spare.

[0066] Preparation of nitrosoguanidine treatment solution: Weigh 20mg of nitrosoguanidine, place it in a 100ml sterile Erlenmeyer flask, add 2ml acetone to dissolve it, then add 18ml Tris buffer (pH6.0, 0.5mol / L) and mix well ,spare.

[0067] Take 10ml of the above-mentioned nitrosoguanidine treatment solution, add 10ml of bacterial suspension, incubate at 30°C and shake for 50-60 minutes, and sample once every 10 minutes. After sampling, first dilute 1000 times to terminate the reaction, then dilute appropriately, and coat the plate. In...

Embodiment 3

[0074] Example 3 Sequencing of 16S rDNA of Bacillus subtilis CGMCC NO.1869 strain

[0075] The 3-hydroxybutanone high-yielding strain SFA-H31, CGMCC NO. 1869 strain, which was selected in Example 2, was entrusted to TaKaRa Biotechnology (Dalian) Co., Ltd. for 16S rDNA sequencing.

[0076] The experimental method is: pick the slant culture in 10μl sterile water, centrifuge at 99℃ and centrifuge to take the supernatant as template, use TaKaRa 16S rDNA Bacterial Identification PCR Kit (Code No.D310), use Forward / Reverse primer2 as primer, Amplify the target fragment. Take 5 μl for agarose gel electrophoresis, use TaKaRa Agarose Gel DNA Purification Kit Ver.2.0 (Code No.DV805A) to cut the gel to recover the target fragments, and use Seq Forward and Seq Reverse Seq Internal as primers to perform DNA sequencing on the recovered products.

[0077] Sequencing results: The 16S rDNA sequence of Bacillus subtilis CGMCC NO.1869 strain is 1468 bp in length, and the nucleotide sequence is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com