Method of lowering content of cyclic oligomer in polyester chip and maintaining excellent hue

A technology for cyclic oligomers and polyester chips, which is applied in the field of reducing the content of cyclic oligomers in polyester chips and maintaining a good color tone, can solve the problems of poor color tone, unworkableness, and high cost, so as to reduce the content , good color, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A treatment method capable of reducing the content of cyclic oligomers in polyester chips and maintaining good color tone, comprising the composite application of antioxidants and phosphorus-containing compounds, and then vacuum-drying the polyester chips for heat treatment.

[0046] Wherein the antioxidant is a compound of the following structure:

[0047] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, its trade name is: Antioxidant 1010

[0048] Structural formula:

[0049]

[0050] Molecular formula: C 73 h 106 o 12

[0051] Phosphorus-containing compounds specifically refer to:

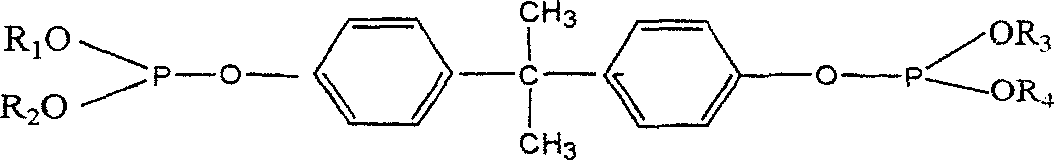

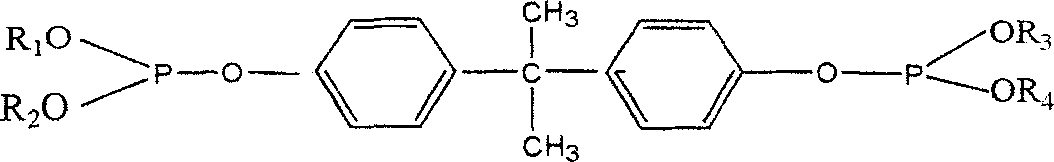

[0052] AP1500, its structural formula is as follows:

[0053]

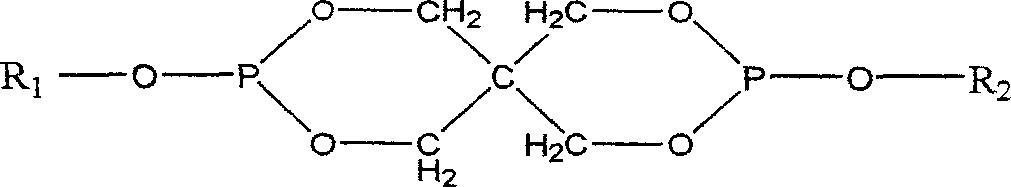

[0054] Asahi Denka PEP36, its structural formula is:

[0055]

[0056] and phosphoric acid

[0057] Concrete reaction process is as follows:

[0058] At a temperature of 250° C., 166 parts (weight) of terephthalic acid are subjected to direct esterification reaction in 75 parts (...

Embodiment 2

[0070] The consumption of catalyzer is: the addition relative to polyester weight is:

[0071] The amount of antioxidant 1010 added is 400ppm

[0072] The amount of phosphorus added in AP1500 is 16ppm

[0073] The amount of magnesium added in the magnesium compound is 40ppm

[0074] The addition amount of antimony element in antimony compound is 200ppm

[0075] The amount of potassium added in potassium hydroxide is 5ppm

[0076] The rest are the same as in Example 1, the section after heat treatment is determined to have a cyclic trimer content of 0.334wt%, and a hue b value of 8.7.

Embodiment 3

[0078] The consumption of catalyzer is: the addition relative to polyester weight is:

[0079] The amount of antioxidant 1010 added is 400ppm

[0080] The amount of phosphorus added in Asahi Denka PEP36 is 40ppm

[0081] The amount of magnesium added in the magnesium compound is 40ppm

[0082] The addition amount of antimony element in antimony compound is 200ppm

[0083] The amount of potassium added in potassium hydroxide is 5ppm

[0084] The rest are the same as in Example 1, the section after heat treatment is determined to have a cyclic trimer content of 0.358wt%, and a hue b value of 7.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com