Permanent magnet oxysome magnetic shoe and producing method thereof

A technology of permanent magnet ferrite and manufacturing method, which is applied in the manufacture of inductance/transformer/magnet, manufacture of stator/rotor body, magnetism of inorganic materials, etc., can solve the problems of easy demagnetization, low level, and poor high and low temperature resistance of magnets. , to achieve the effect of increasing density and degree of orientation, increasing degree of orientation and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of permanent magnet ferrite magnetic tile, is made up of main component and additive (expressed in wt.%): main component calcined material is: iron red Fe2O3 and strontium carbonate SrCO3 carry out batching according to stoichiometric as n=6 Take 96.5%; Additive: CaCO 3 1.1%, SiO 2 0.5%, Al 2 o 3 0.5%, H 3 BO 3 0.3%, BiO 3 0.3%, Co 3 o 4 0.4%, La 2 o 3 0.4%.

Embodiment 2

[0030] Embodiment 2: A kind of permanent ferrite magnetic tile, is made up of main component and additive (expressed with wt.%): Main component: calcined material: iron red Fe2O3 and strontium carbonate SrCO3 carry out batching according to stoichiometry as n=6 Take 96.8%; Additive: CaCO 3 1%, SiO 2 0.4%, Al 2 o 3 0.6%, H 3 BO 3 0.2%, BiO 3 0.3%, Co 3 o 4 0.3%, La 2 o 3 0.4%.

Embodiment 3

[0031] Embodiment 3: a kind of permanent ferrite magnetic tile, is made up of main component and additive (expressed in wt.%): main component: calcined material: iron red Fe2O3 and strontium carbonate SrCO3 carry out batching for n=6 according to stoichiometry Take 96.4%; Additive: CaCO 3 1.2%, SiO 2 0.3%, Al 2 o 3 0.8%, H 3 BO 3 0.25%, BiO 3 0.25%, Co 3 o 4 0.5%, La 2 o 3 0.3%.

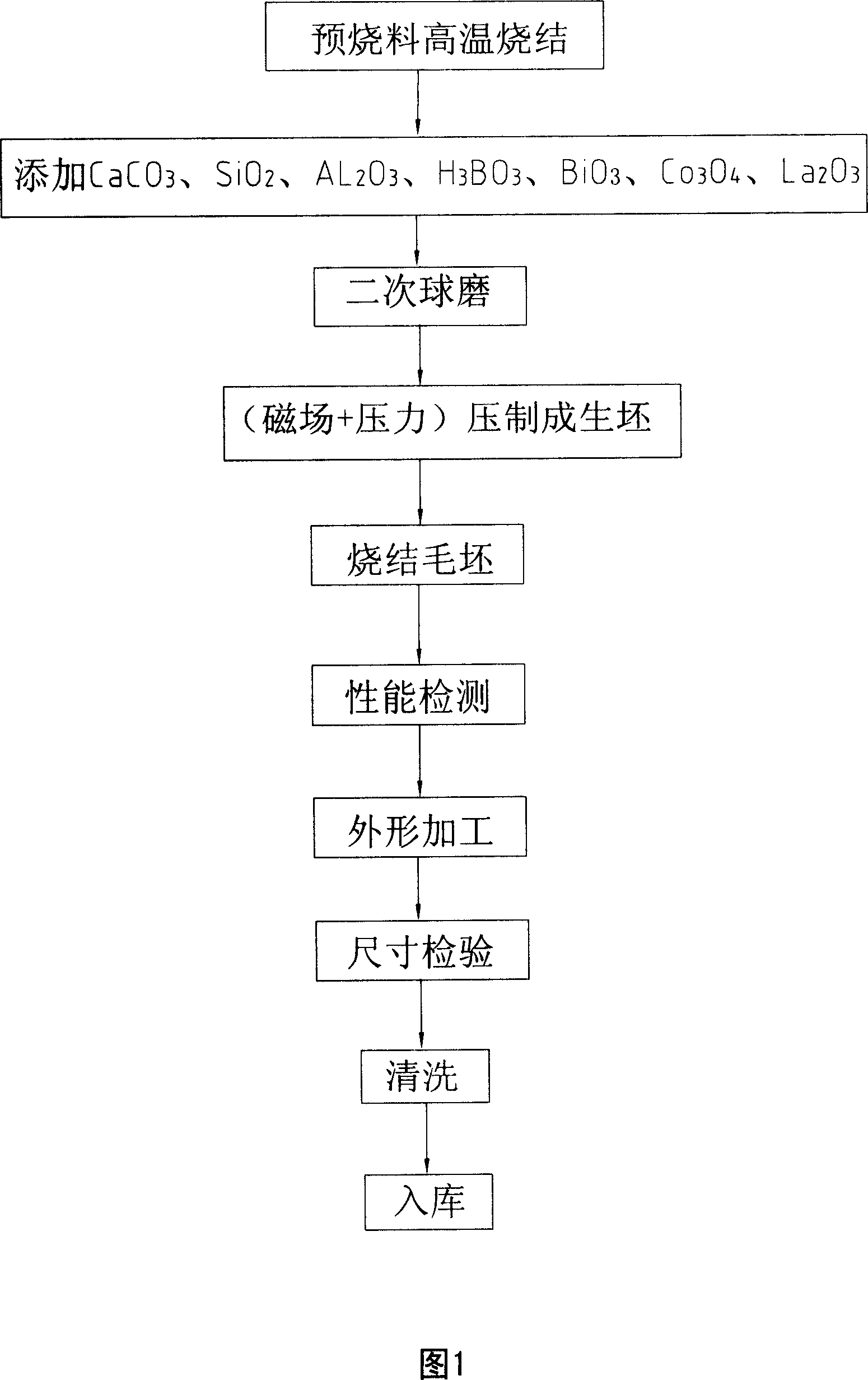

[0032]The manufacturing method of the permanent ferrite magnetic tile includes the following steps in sequence: 1) high-temperature sintering of the pre-sintered material, 2), adding CaCO 3 , SiO2, Al 2 o 3 、H 3 BO 3 、BiO 3 、Co 3 o 4 , La 2 o 3 , 3) secondary ball milling, 4), (magnetic field + pressure) pressed into green body, 5) sintered blank, 6), performance testing, 7) shape processing, 8) dimension inspection, 9) cleaning, 10), storage . The specific implementation can be carried out according to the following procedures:

[0033] 1) High temperature sintering of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com