Electric device with nanowires comprising a phase change material and manufacturing method thereof

A technology of phase change materials and electrical devices, which is applied in the field of manufacturing electrical devices and can solve problems such as high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

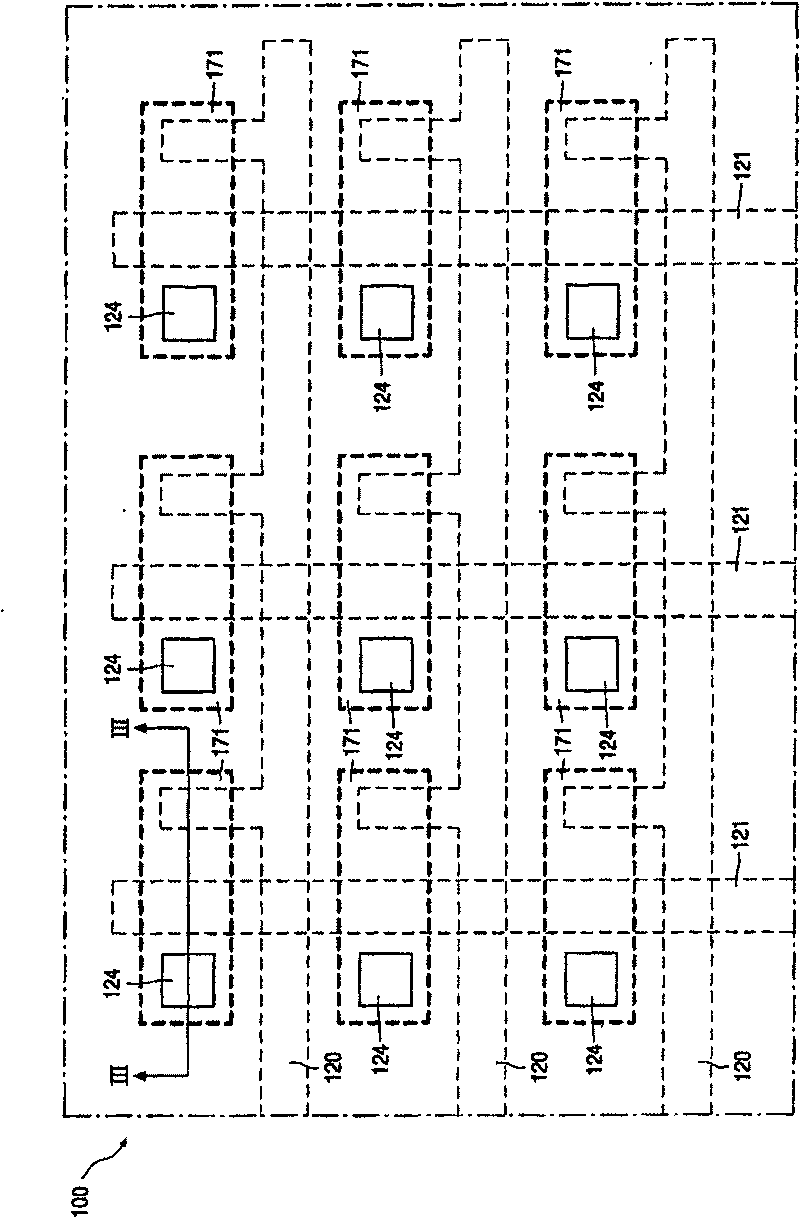

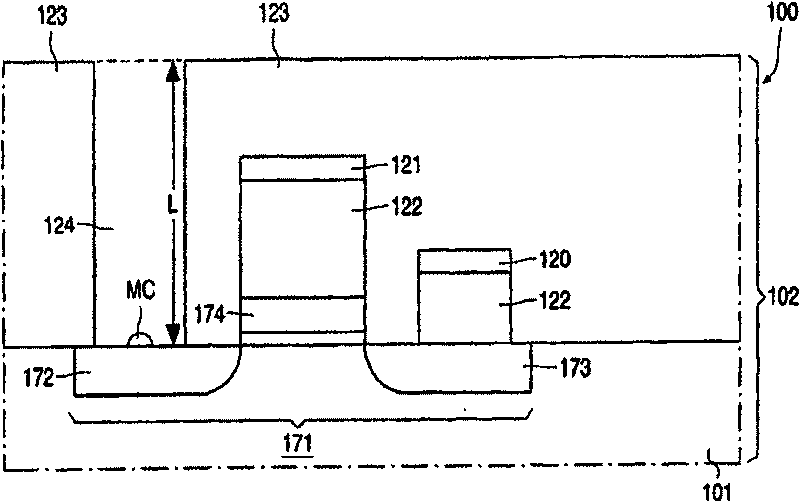

[0071] as in Figure 2-6 At various stages of fabrication shown in , an embodiment of an electrical device 100 has a body 102 comprising a substrate 101 which may comprise, for example, a monocrystalline p-doped silicon semiconductor wafer. The body also includes an array of selection means 171 . exist Figure 2-6 In the illustrated embodiment, the electrical device 100 has a 3x3 array, but the invention is neither limited to arrays of this size nor shape. The body 102 also comprises a grid of select lines 120 , 121 such that each memory cell is accessed via a respective select line 120 , 121 connected to a respective select means 171 .

[0072] exist Figure 2-6 In the illustrated embodiment, the selection means 171 comprise Metal Oxide Semiconductor Field Effect Transistors (MOSFETs), and more particularly NMOS transistors. The MOSFET has an n-doped source region 172 , an n-doped drain region 173 and a gate region 174 . Source region 172 and drain region 173 may include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com