Bending single-phase driven rotary ultrasonic motor

A single-phase drive, ultrasonic motor technology, used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of poor speed uniformity, low efficiency, and large radial friction. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

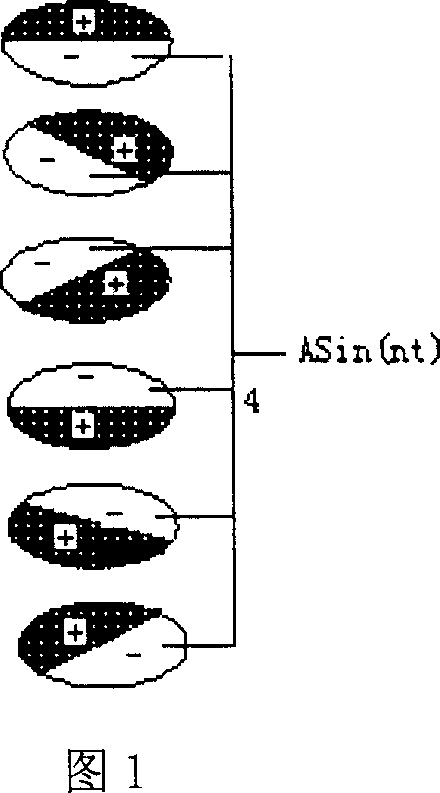

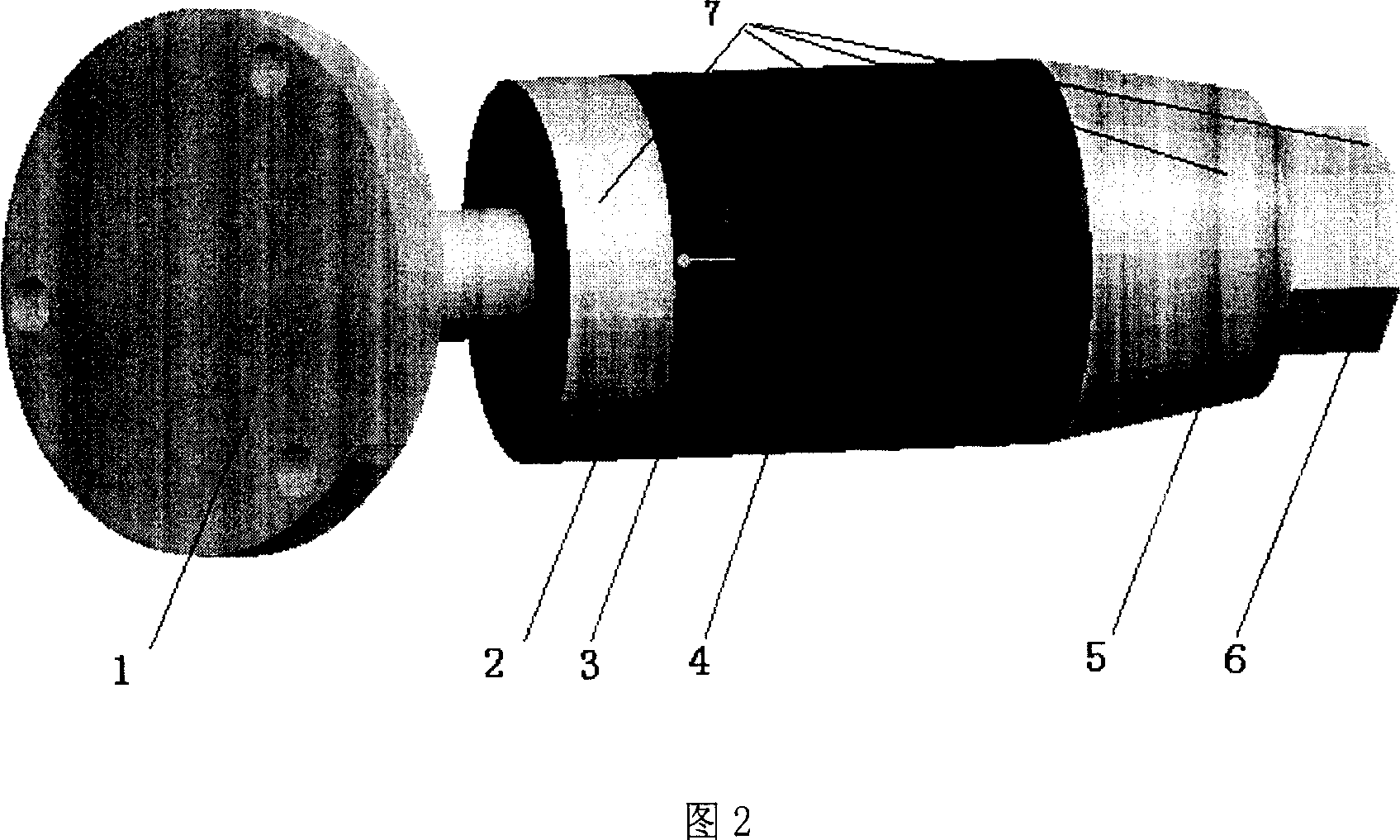

[0033] The invention is a novel ultrasonic rotating electrical machine driven by a single-phase power supply and developed by utilizing the piezoelectric effect of a piezoelectric ceramic plate to excite a bending vibration mode of a stator. It is mainly composed of six piezoelectric ceramic sheets 4, a screw rod 2, a press shaft sleeve 5, a rotor 1, a press nut 6 and a gasket 3. The layout of piezoelectric ceramic sheets is shown in Figure 1. Each piece of piezoelectric ceramic sheet is divided into two parts with the diameter as the axis of symmetry and polarized in opposite phases. After the same voltage is applied, one part expands and the other part shrinks.

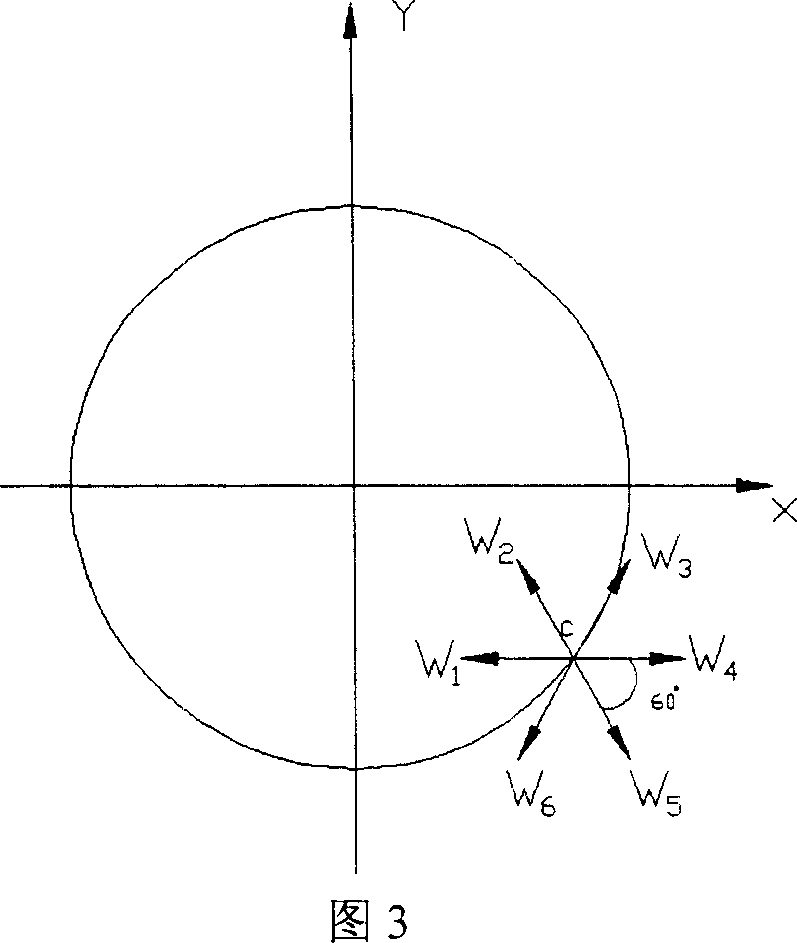

[0034] It can be seen from Figure 2 that the stator is fixed on the central shaft by 6 pieces of piezoelectric ceramic gaskets that are dislocated by 60 degrees respectively through the compression nut 6 and the pressure shaft sleeve 5 . The structure of the body is designed to be cone-shaped. The rotor 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com