Biological desulfurizing device for transforming sulfur-containing compound to elemental sulfur

A biological desulfurization and elemental sulfur technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water pollutants, etc., can solve problems such as odor and odor, lower pH, and lower quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

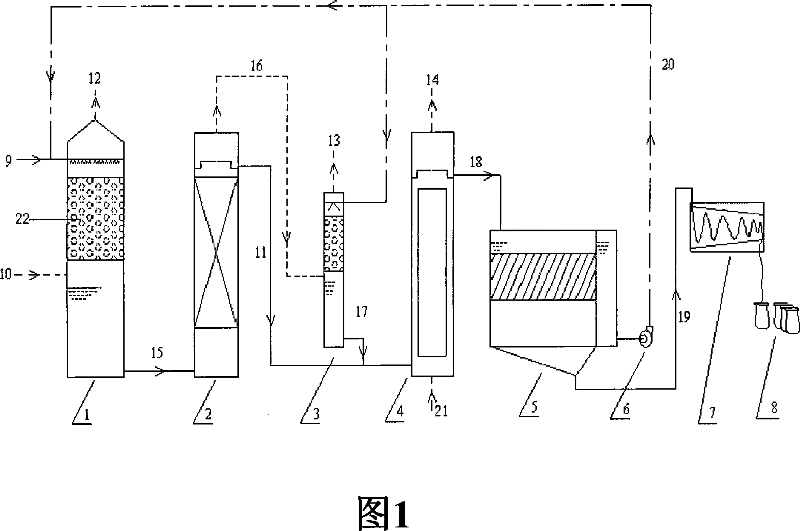

[0016] Example 1: Flue gas desulfurization

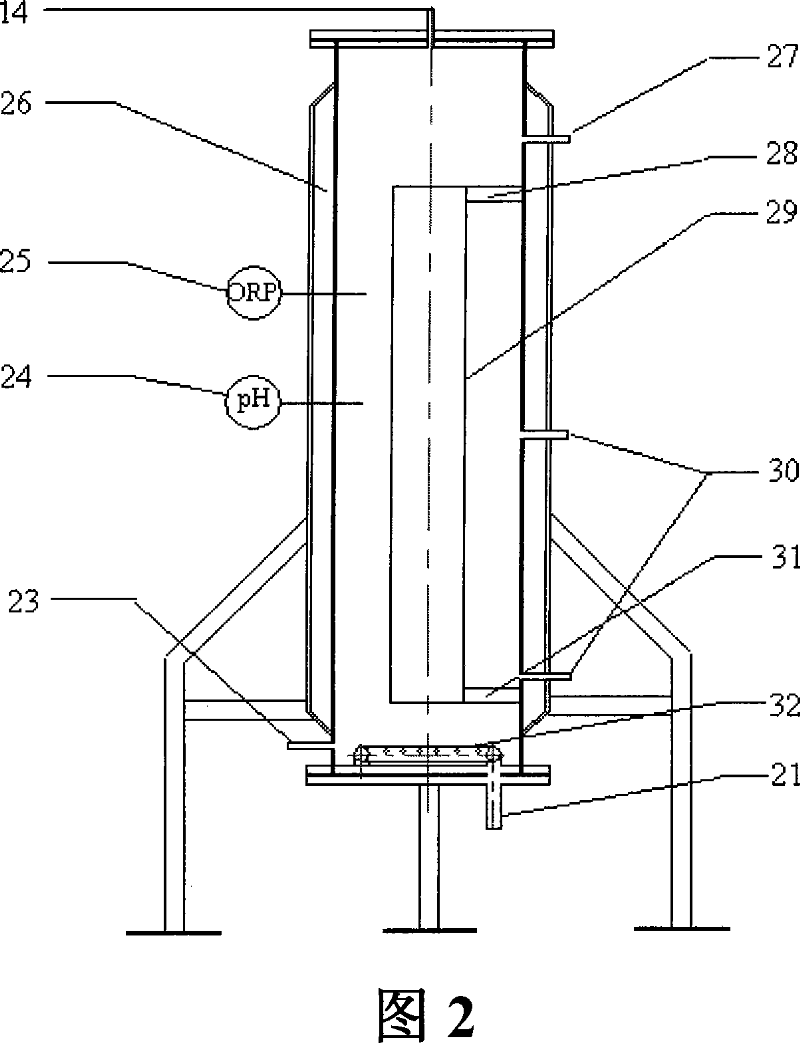

[0017] Flue gas produced by thermal power plants, in SO 2 The absorption tower is absorbed by NaOH solution; the absorption liquid is reacted with the citric acid fermentation wastewater in the anaerobic sulfate reduction anaerobic reactor inoculated with anaerobic granular sludge, and the temperature is controlled at 35-37 °C and the pH value is 6.5-7.5; the gas produced Pass into the H2S absorption tank and absorb H with NaOH solution 2 S, the absorption liquid enters the elemental sulfur generation reactor, in the elemental sulfur generation reactor: the temperature is 30-40°C, the pH value is 7-8, the ORP is -340mv~-360mv, and finally the elemental sulfur is precipitated in the sedimentation tank, and the Filter and store.

Embodiment 2

[0018] Embodiment 2: Desulfurization of sulfate wastewater

[0019] The molasses alcohol wastewater with high concentration of sulfate reacts in the sulfate reduction anaerobic reactor inoculated with anaerobic granular sludge, the temperature is controlled at 35-37 °C, and the pH value is 6.5-7.5; the generated gas is passed into H 2 S absorption tank absorbs H with NaOH solution 2 S, the absorption liquid enters the elemental sulfur generation reactor, in the elemental sulfur generation reactor: the temperature is 30-40°C, the pH value is 7-8, the ORP is -340mv~-360mv, and finally the elemental sulfur is precipitated in the sedimentation tank, and the Filter and store.

Embodiment 3

[0020] Example 3: Desulfurization of sulfide-containing wastewater

[0021] Wastewater with a sulfide concentration of 400mg / L enters the elemental sulfur generation reactor. In the elemental sulfur generation reactor: the temperature is 30-40°C, the pH value is 7-8, the ORP is -340mv~-360mv, and finally the elemental sulfur is in the sedimentation tank Precipitated in medium and stored after press filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com