Powder coal ash expanding self-dense concrete for filling square steel pipe

A technology of self-compacting concrete and fly ash, which is applied in the field of concrete in the technical field of building materials, can solve the problems of concrete expansion cracking, unqualified cement stability, and high content of free calcium oxide, so as to reduce the dosage, reduce the amount of cement, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

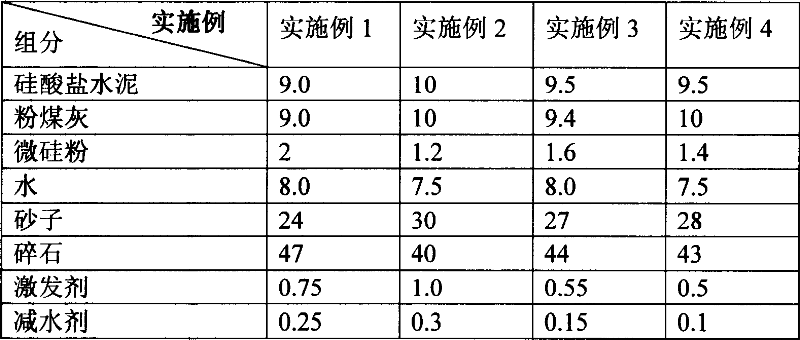

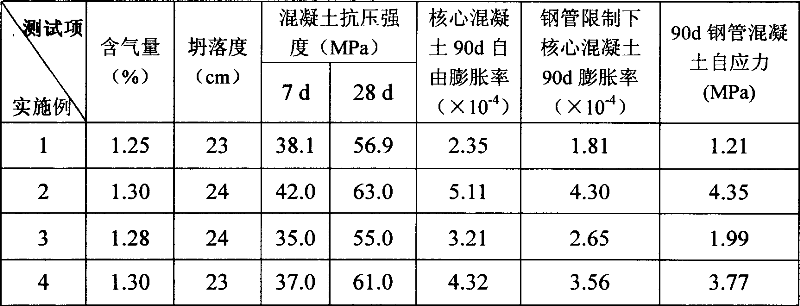

[0029] The large-volume fly ash high-strength expansive self-compacting concrete used to fill square steel pipes is composed of ordinary Portland cement, fly ash, microsilica fume, sand, gravel, activator, retarding water reducer and water Proportion, complete mixing and pouring into 120mm×120mm×400mm square cross-section cold-formed steel pipes by the following process: first dry mix the cement, fly ash, micro-silica fume and activator according to the design requirements of the mix ratio for 30 seconds , add coarse aggregate and fine aggregate, the stirring time is 30 seconds to 1 minute, add 60% water and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com