Modification bamboo charcoal having Ag and porous TiO2 and the preparing method

A bamboo charcoal and modified technology, applied in the field of modified bamboo charcoal products and their preparation, can solve the problems of no light source, agglomeration, affecting the photocatalytic performance of bamboo charcoal, etc., and achieve the effect of high negative ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

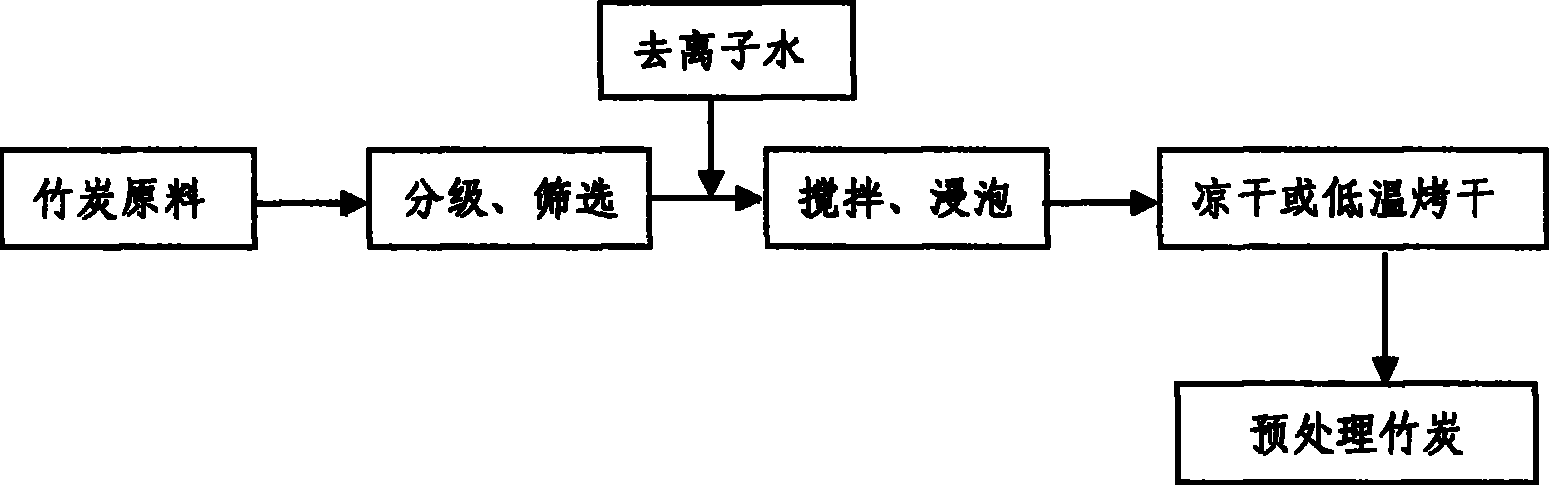

[0031] Such as figure 1 Shown, the preparation of the raw material of modified bamboo charcoal, the raw material of bamboo charcoal is graded and screened, add deionized water to soak, stir, dry or dry at low temperature to obtain the pretreated bamboo charcoal raw material. The specific surface area of the pretreated bamboo charcoal raw material is 100-250m 2 / g.

Embodiment 2

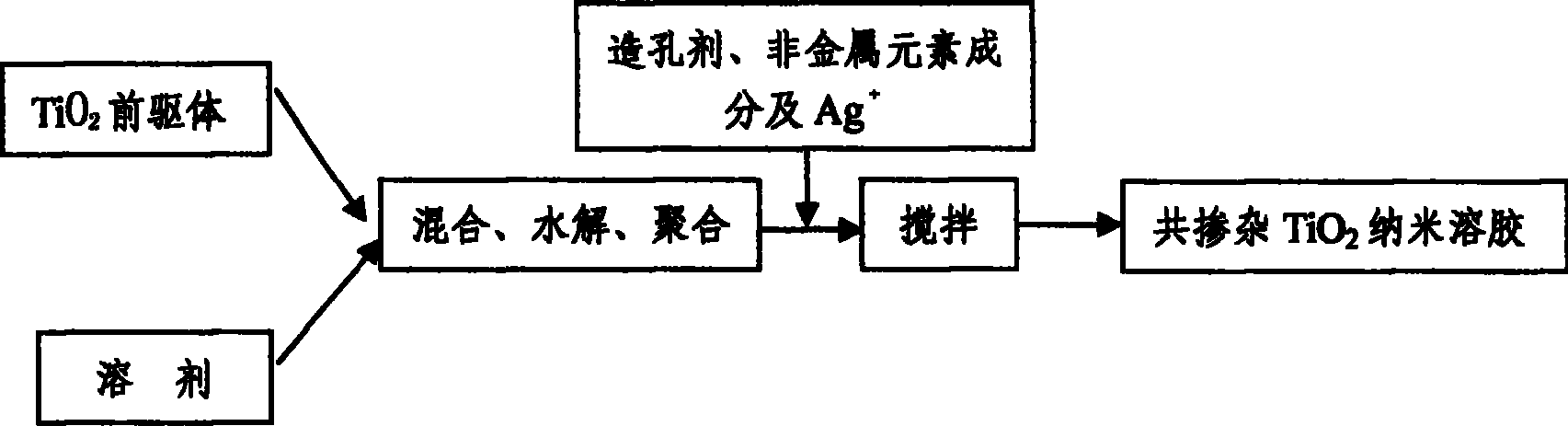

[0033] Such as figure 2 A TiO co-doped with pore-forming agent Ag / N is shown 2 The preparation method of nano-sol, its raw material conditions: take butyl titanate, dehydrated alcohol, hydrochloric acid and deionized water as main raw materials, hexamethylenetetramine is nitrogen source, and the molar ratio of N and Ti is 0.5%; Nitric acid Silver was complexed with citric acid to introduce silver ions, Ag + The molar ratio with Ti is 0.1%, polyethylene glycol is 3% by weight of the sol.

[0034] At room temperature, a certain amount of butyl titanate was slowly dropped into absolute ethanol, and after vigorous stirring for 30 minutes, a uniform bright yellow clear solution was obtained; then a certain proportion of deionized water, absolute ethanol, hydrochloric acid, Hexamethylenetetramine, citric acid complexed with silver nitrate, and polyethylene glycol form a mixed solution, which is slowly added dropwise to the above-mentioned clear solution, and the pH value of the s...

Embodiment 3

[0037] A Co-doped TiO Containing Porogen Ag / N 2 The preparation method of nano-sol, its raw material conditions: take butyl titanate, dehydrated alcohol, hydrochloric acid and deionized water as main raw materials, hexamethylenetetramine is nitrogen source, and the molar ratio of N and Ti is 1.0%; Nitric acid Silver was complexed with citric acid to introduce silver ions, Ag +The molar ratio with Ti is 0.3%, polyethylene glycol is 3.5% by weight of the sol.

[0038] At room temperature, a certain amount of butyl titanate was slowly dropped into absolute ethanol, and after vigorous stirring for 30 minutes, a uniform bright yellow clear solution was obtained; then a certain proportion of deionized water, absolute ethanol, hydrochloric acid, Hexamethylenetetramine, citric acid complexed with silver nitrate, and polyethylene glycol form a mixed solution, which is slowly added dropwise to the above-mentioned clear solution, and the pH value of the solution is controlled at about 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com