Modified activated charcoal for fuel desulfuration and preparation method and device thereof

A technology of activated carbon and modification, applied in the field of preparation of modified activated carbon, can solve the problems of difficult deep removal, complicated desulfurization process, space obstruction, etc., and achieve the effects of improving adsorption capacity, pollution-free environment, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

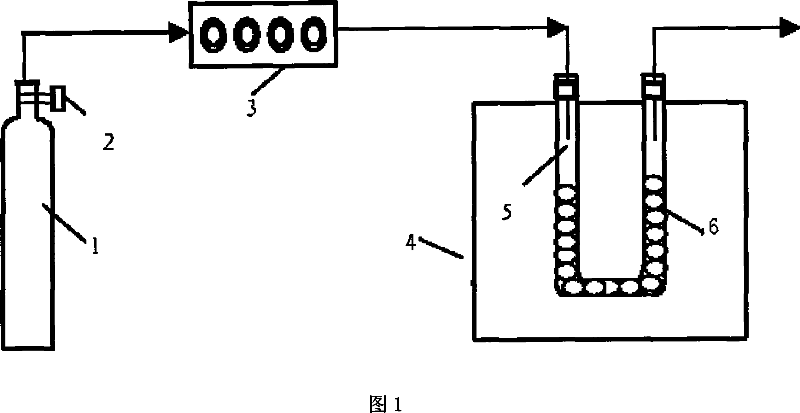

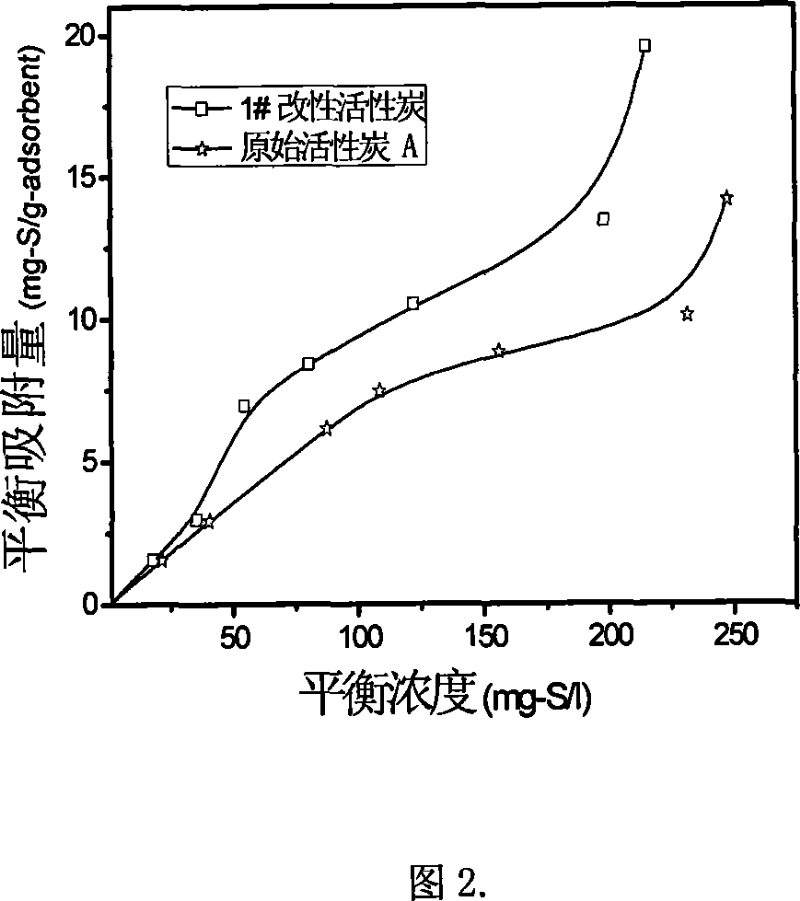

[0033] According to the device shown in Figure 1, the SY-13 original activated carbon A produced by Heilongjiang Senyuan Activated Carbon Co., Ltd. was screened to obtain uniform particles of 40-60 mesh size, which were pickled with 0.1mol / l hydrochloric acid and 0.1mol / l sodium hydroxide. Alkali washing and water washing remove the inorganic and organic impurities on the surface of the activated carbon, and dry it for later use. Take 3g of activated carbon and place it in a U-shaped tube. Put the U-shaped tube filled with activated carbon in the microwave reactor, connect the gas circuit and check the air tightness, first open the nitrogen cylinder, set the flow rate of the nitrogen line to 3cm / min, feed nitrogen for 30min, and then turn on the microwave reactor. The microwave power is set to 100w, the working time is set to 20min, and the nitrogen line flow rate is 0.5cm / min to modify the surface of the activated carbon. After the reaction is completed, nitrogen is introduce...

Embodiment 2

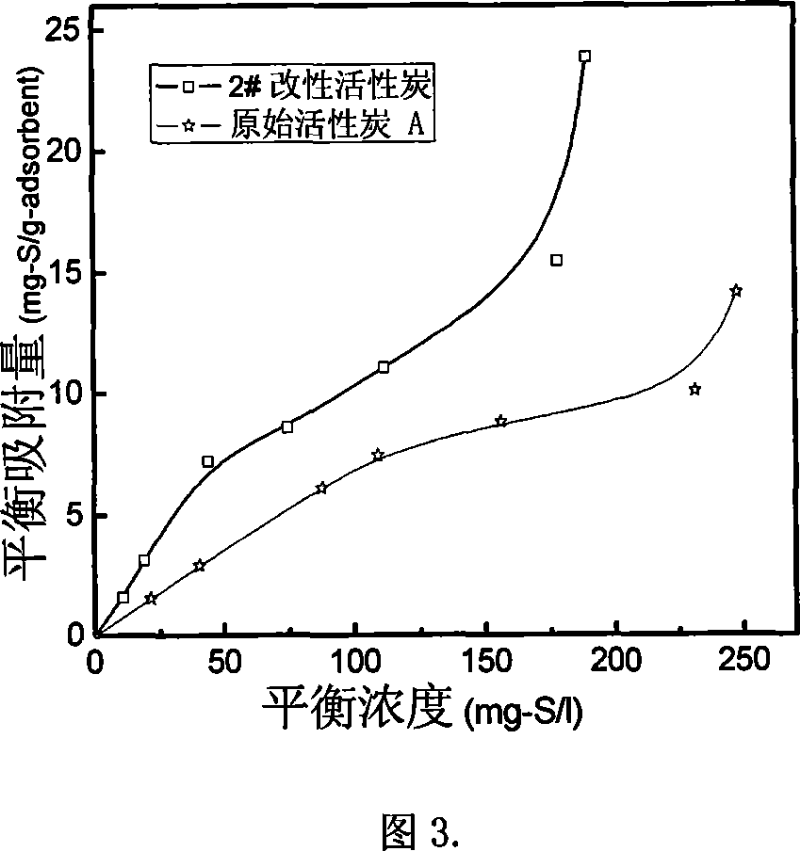

[0035] According to the device shown in Figure 1, the SY-13 original activated carbon A produced by Heilongjiang Senyuan Activated Carbon Co., Ltd. was screened to obtain uniform particles of 40-60 mesh size, which were pickled with 0.1mol / l hydrochloric acid and 0.1mol / l sodium hydroxide alkali Wash and wash with water to remove inorganic and organic impurities on the surface of activated carbon, and dry it for later use. Take 3g of activated carbon and place it in a U-shaped tube. Put the U-shaped tube filled with activated carbon in the microwave reactor, connect the gas circuit and check the air tightness, first open the nitrogen cylinder, set the flow rate of the nitrogen line to 3cm / min, feed nitrogen for 30min, and then turn on the microwave reactor. The microwave power is set to 1200w, the working time is set to 3min, and the nitrogen line flow rate is 8cm / min to modify the surface of the activated carbon. Activated carbon samples. As shown in Table 1 and Table 2, Bo...

Embodiment 3

[0037] According to the device shown in Figure 1, the SY-6 original activated carbon B produced by Heilongjiang Senyuan Activated Carbon Co., Ltd. was screened to obtain uniform particles of 40-60 mesh size, which were pickled with 0.1mol / l hydrochloric acid and 0.1mol / l sodium hydroxide alkali Wash and wash with water to remove inorganic and organic impurities on the surface of activated carbon, and dry it for later use. Take 3g of activated carbon and place it in a U-shaped tube. Put the U-shaped tube filled with activated carbon in the microwave reactor, connect the gas circuit and check the air tightness, first open the nitrogen cylinder, set the flow rate of the nitrogen line to 3cm / min, feed nitrogen for 30min, and then turn on the microwave reactor. The microwave power is set to 900w, the working time is set to 10min, and the nitrogen line flow rate is 5cm / min to modify the surface of the activated carbon. Activated carbon samples. As shown in Table 1 and Table 2, Boe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com