Antirust agent

A rust inhibitor, the technology of carbon atom number, applied in the direction of anti-corrosion composition, detergent composition, non-surface-active detergent composition, etc., can solve the problems of inability to prevent rust, rust, not easy to be completely replaced by oxygen, etc. , to achieve the effect of saving time and reagent costs and reducing reagent costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

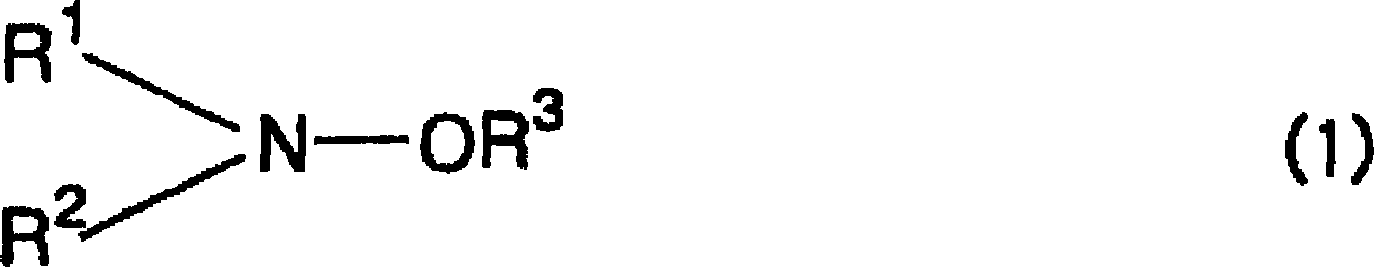

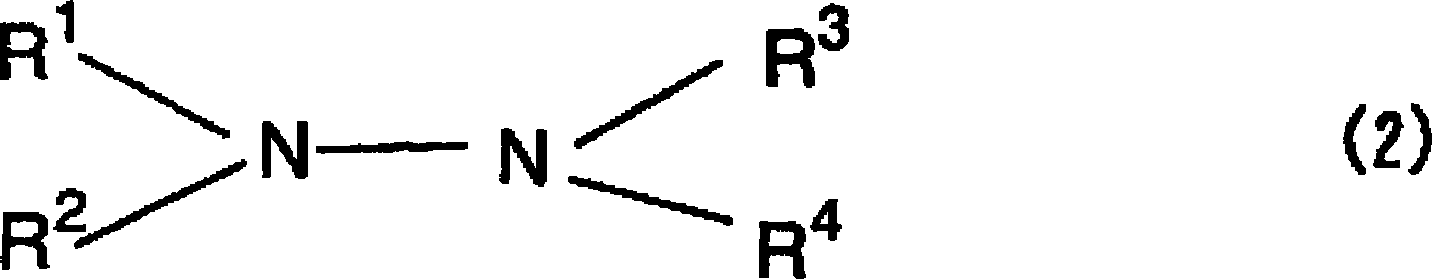

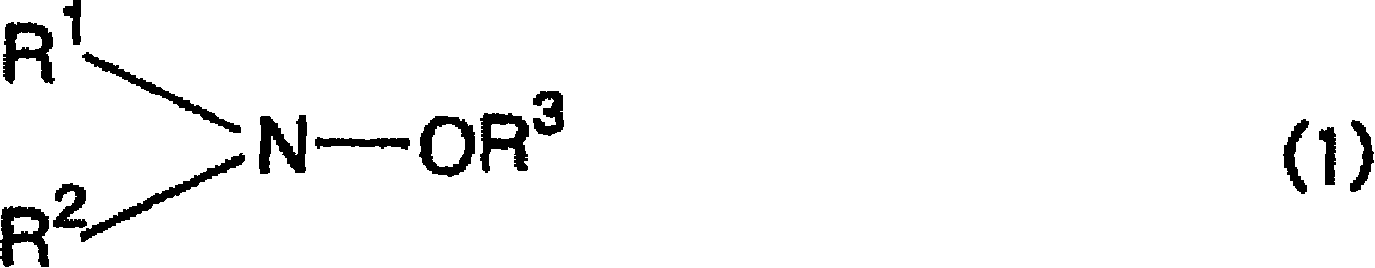

Method used

Image

Examples

Embodiment 1

[0037] 82 parts of polyethylene glycol diglycidyl ether (Denakol EX-841, manufactured by Nagase Chemical Co., Ltd., epoxy equivalent: 370 g / eq) and 2 parts of glycerin poly(ethylene glycol) previously heated to 60° C. Glycidyl ether (デナコール EX-313, manufactured by Nagase Chemical Co., Ltd., epoxy equivalent: 141g / eq) (epoxy equivalent: active hydrogen equivalent = 1:2.0) was added to a 500 ml beaker, and further 0.1 Parts of benzyldimethylamine as a curing accelerator, mixed and stirred. 16 parts of m-xylylenediamine (active hydrogen equivalent: 34 g / eq) was added thereto, and further stirred. This mixed solution was poured into an aluminum molding die, heated at 80° C. for 1 hour in a desiccator, and then heated to 120° C. for 1 hour to obtain a cured resin. The resin cured product was pulverized in a mortar, and 3 g of the pulverized product was immersed in 100 ml of a 5% by weight aqueous solution of hydroxylamine at 25° C. for 24 hours. Then, the water-absorbing resin cur...

Embodiment 2

[0042] The same procedure as in Example 1 was carried out except that 5% by weight of hydrazine was used instead of 5% by weight of hydroxylamine. Table 1 shows the results of the gasification rust prevention test.

Embodiment 3

[0044] Except that 5% by weight of N,N-diethylhydroxylamine was used instead of 5% by weight of hydroxylamine, the same procedure was carried out as in Example 1. Table 1 shows the results of the gasification rust prevention test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com