Sewage biological desulphurizing device

A biological desulfurization and biogas technology, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of uncontrollable oxygen content, temperature and humidity, and achieve easy control of oxygen supply and humidity, and convenient manufacturing and the effect of reducing the cost of use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

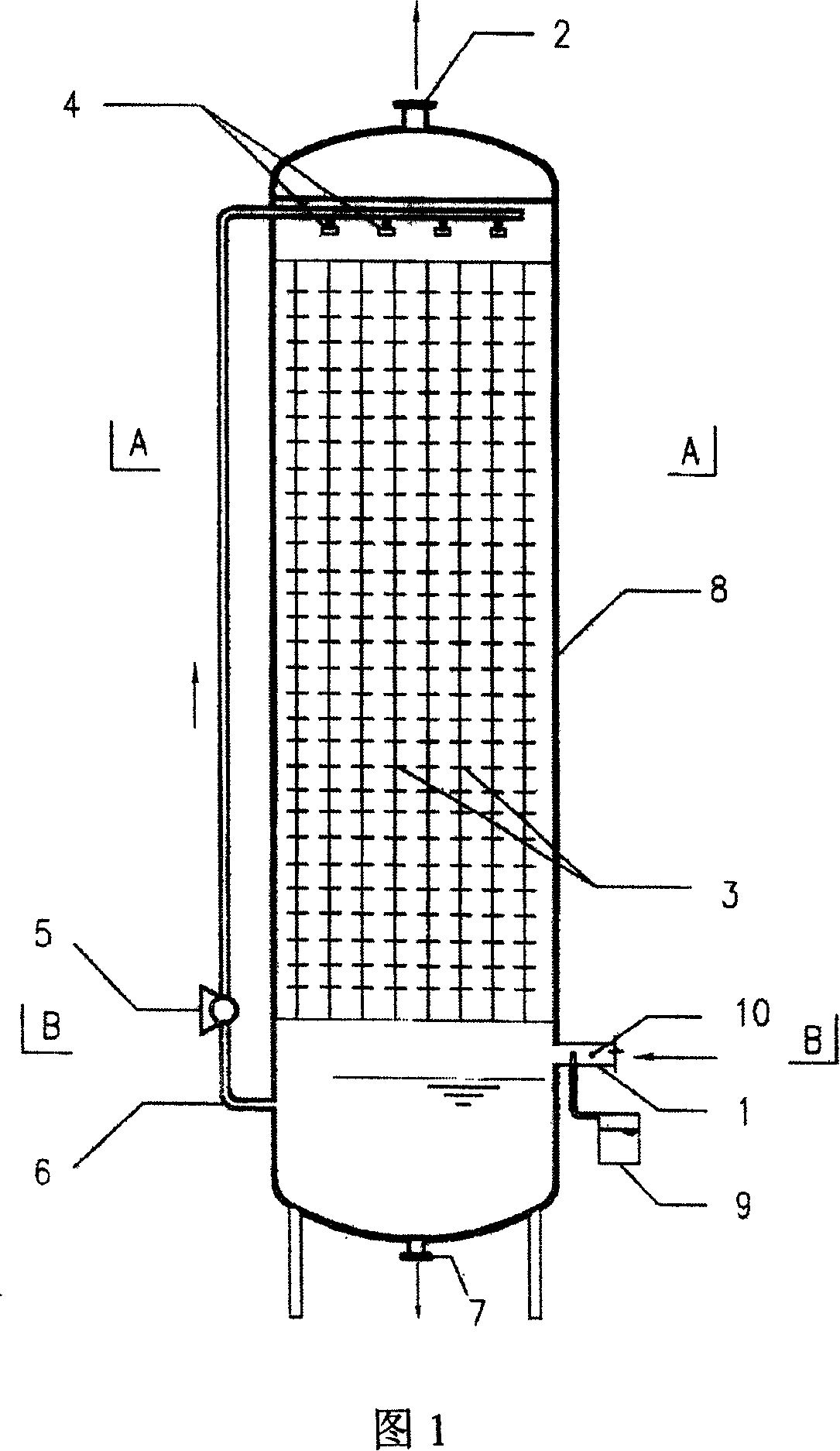

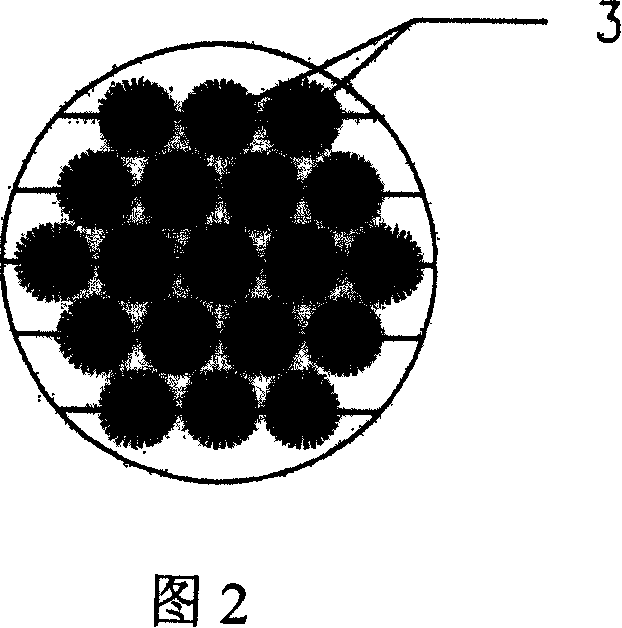

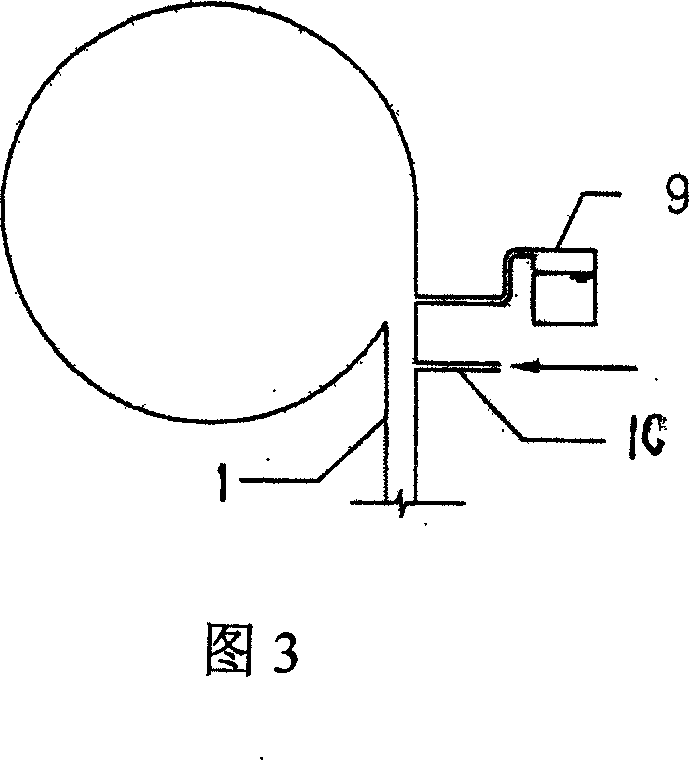

[0023] Example 1. As shown in Fig. 1, the biogas desulfurization device of the present invention is an upright desulfurization tower, the biogas outlet 2, the biogas inlet 1 and the discharge port 7 are respectively arranged at the top, lower waist and bottom of the tower, and the nutrient solution section is formed below the biogas inlet 1. A number of biological fillers 3 with high specific surface are placed in the desulfurization tower (such as commercially available wire mesh fillers, whose specific surface area can reach 250m 2 / m 3 , to increase the amount of biofilm, see Figure 2), the top of the filler is provided with a nutrient solution nozzle 4, the upper end of the delivery pipe 6 with the return pump 5 passes through the desulfurization tower wall and communicates with the nozzle 4, and its lower end passes through the desulfurization tower wall and is submerged into the in the lower nutrient solution. There is an oxygen measuring probe connected to the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com