Magnetron sputtering coating method under multi-stage acceleration mode

A magnetron sputtering coating, acceleration mode technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem of low bonding strength between film and substrate surface, low gas ionization rate, energy limited and other problems, to achieve the effect of improving the quality of sputtering coating, simple process method and increasing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

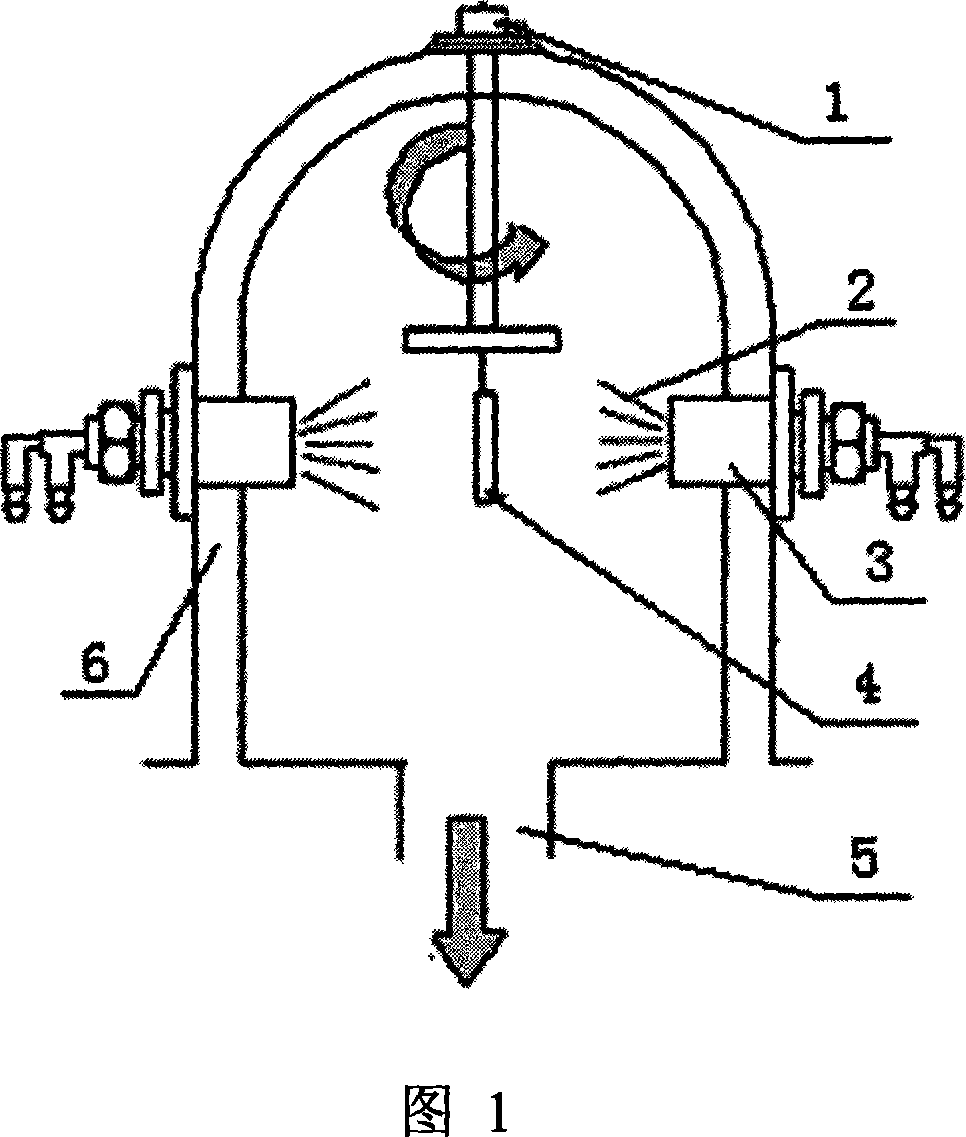

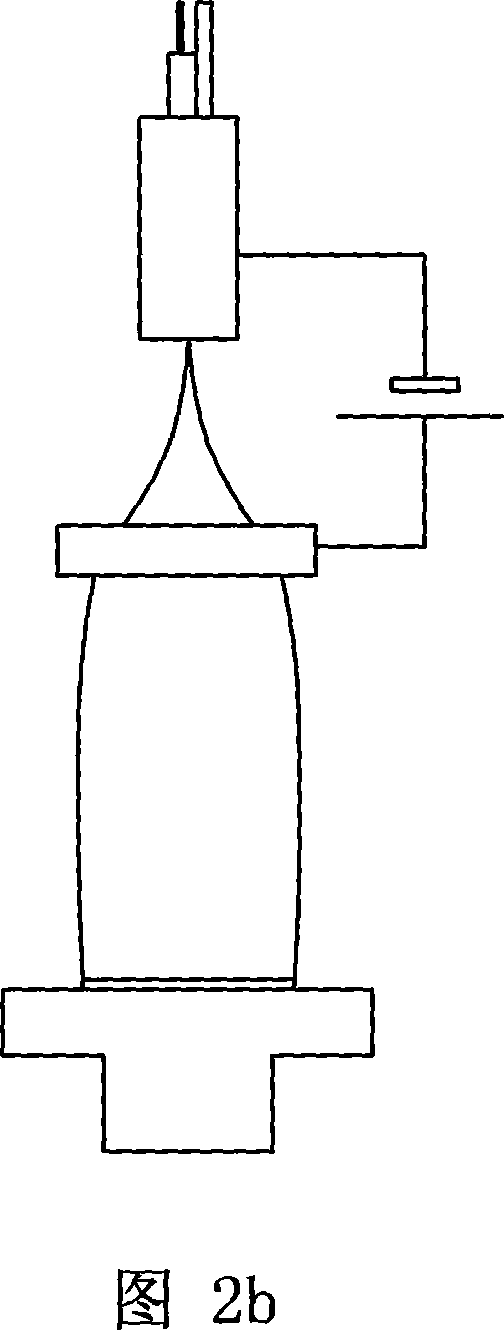

[0012] As shown in Figure 1 and Figure 2B,

[0013] A power supply auxiliary electrode is set between the target material 3 and the base material on the workpiece frame 4 to form a secondary accelerating electric field. A DC power supply is used, the positive pole of the power supply is connected to the base material, and the negative pole of the power supply is connected to the target material. During the coating process, the rotating motor 1 drives the workpiece holder 4 and the base material on it to rotate, and after the vacuum chamber 6 is evacuated 5, it is filled with argon gas, and a radio frequency voltage is applied to generate a glow discharge phenomenon, forming a low-temperature plasma 2; at the same time Applying a secondary accelerating electric field, the direction of the electric field is consistent with the direction of particle acceleration, increases the energy of energetic particles in the electromagnetic field, improves the ionization rate of the gas and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com