Preparation method of mono-molecule layer polysilane fluorescent sensing film sensitive to nitro-aromatic compounds

A monolayer, fluorescence sensing technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., to achieve the effects of high sensitivity, mild reaction conditions, and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

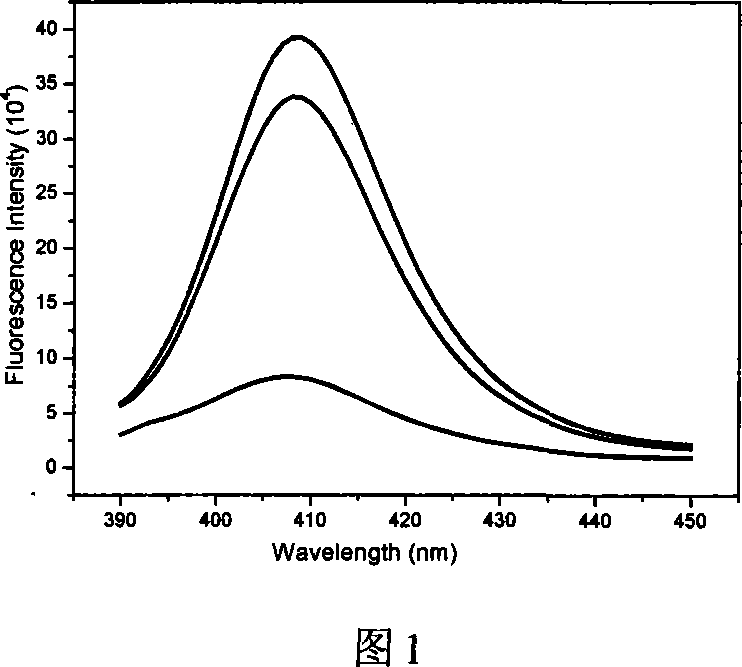

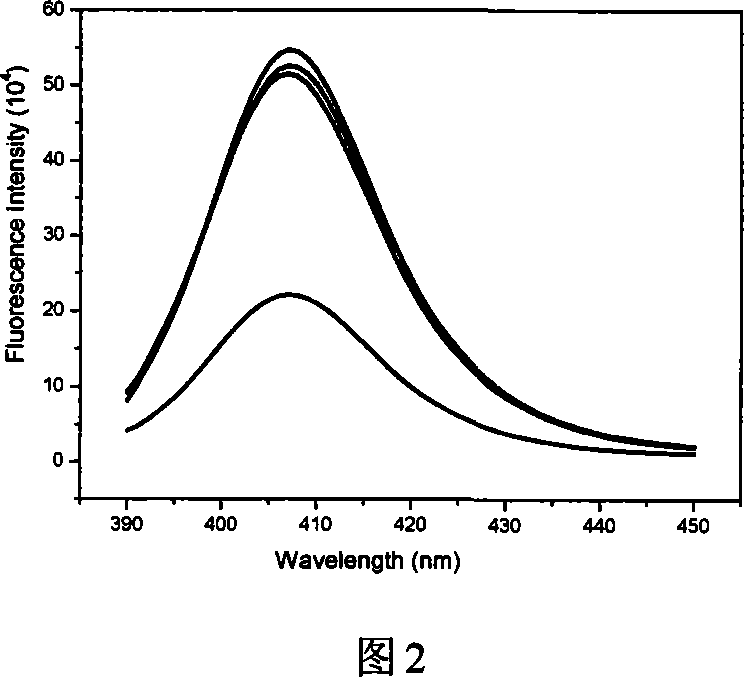

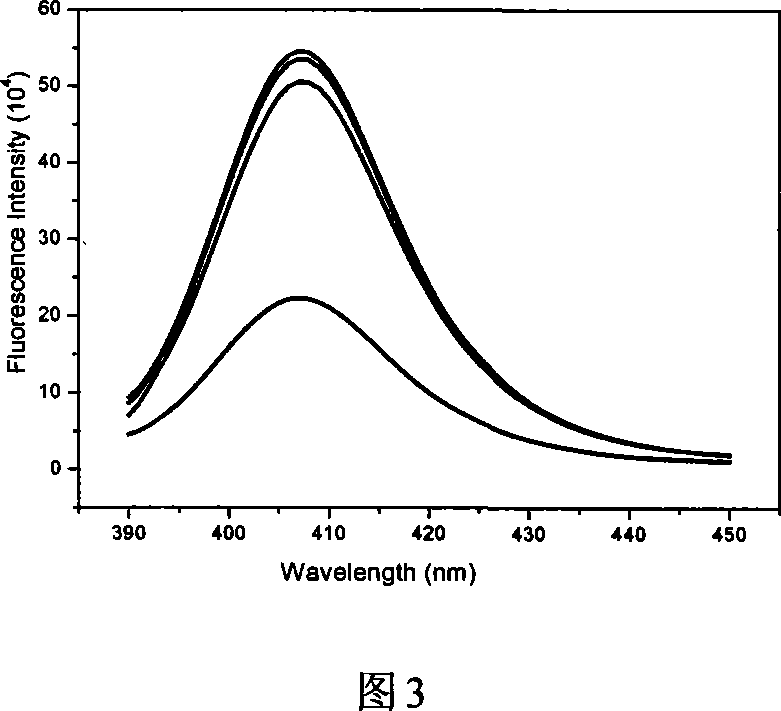

Image

Examples

Embodiment 1

[0042] Taking the sodium metal raw material 3g used for the preparation of the monomolecular layer polydiphenylsilane fluorescent sensing film of the present invention as an example, the preparation method is as follows:

[0043] 1. Tailoring the substrate

[0044] Cut the glass plate into 0.9×2.5cm 2 sized rectangular piece of glass.

[0045] 2. Prepare lotion

[0046] Mix 30% hydrogen peroxide and 98% sulfuric acid at a volume ratio of 7:3 to make a washing solution.

[0047] 3. Preparation of activated substrate

[0048] First wash the glass piece with water and ethanol, dry it, put it into the lotion, heat it at 80-100°C for 1-2 hours, cool it naturally, wash the glass piece with twice distilled water, wash off the lotion remaining on the surface, and blow it with a hair dryer. Dry to make an activated substrate.

[0049] 4. Preparation of silanized substrate

[0050] Put the activated substrate into a solution with a volume ratio of 3-chloropropyltrimethoxysilane an...

Embodiment 2

[0058] Taking the sodium metal raw material 3g used for the preparation of the monomolecular layer polydiphenylsilane fluorescent sensing film of the present invention as an example, the preparation method is as follows:

[0059] In this embodiment, in the preparation of silylated substrate 4, the activated substrate is put into a solution whose volume ratio of 3-chloropropyltrimethoxysilane and toluene solution is 1:100, and refluxed for 3 hours. Others in this step Process is identical with embodiment 1. In step 5 of preparing polysiladiphenylane, in a 500mL three-necked flask equipped with an electromagnetic stirrer, a reflux condenser and a constant pressure dropping funnel, 3g of sodium was added under the condition of 0.6-0.8mL / s argon gas, Heat 60g of toluene to 110°C, reflux, and stir for 1 hour with an electromagnetic stirrer at a speed of 1800 rpm; mix 16.51g of diphenyldichlorosilane with 60g of toluene, that is, the molar ratio of diphenyldichlorosilane to sodium i...

Embodiment 3

[0061] Taking the sodium metal raw material 3g used for the preparation of the monomolecular layer polydiphenylsilane fluorescent sensing film of the present invention as an example, the preparation method is as follows:

[0062] In this embodiment, in the preparation of silylated substrate 4, the activated substrate is put into a solution whose volume ratio of 3-chloropropyltrimethoxysilane and toluene solution is 1:120, and refluxed for 6 hours. Others in this step Process is identical with embodiment 1. In step 5 of preparing polysiladiphenylane, in a 500mL three-necked flask equipped with an electromagnetic stirrer, a reflux condenser and a constant pressure dropping funnel, 3g of sodium was added under the condition of 0.6-0.8mL / s argon gas, Heat 90g of toluene to 110°C, reflux, and stir for 1 hour with an electromagnetic stirrer at a speed of 1800 rpm; mix 16.51g of diphenyldichlorosilane with 90g of toluene, that is, the molar ratio of diphenyldichlorosilane to sodium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com