A zinc oxide base nano semiconductor electronic self-rotation material and its synthesizing method

A nano-semiconductor and electron spin technology, applied in the direction of the magnetism of inorganic materials, can solve the problems of poor reproducibility of ferromagnetism at room temperature, unclear magnetic origin, easy to mix, etc., and achieve superior magnetic properties and superior high-temperature ferromagnetism , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

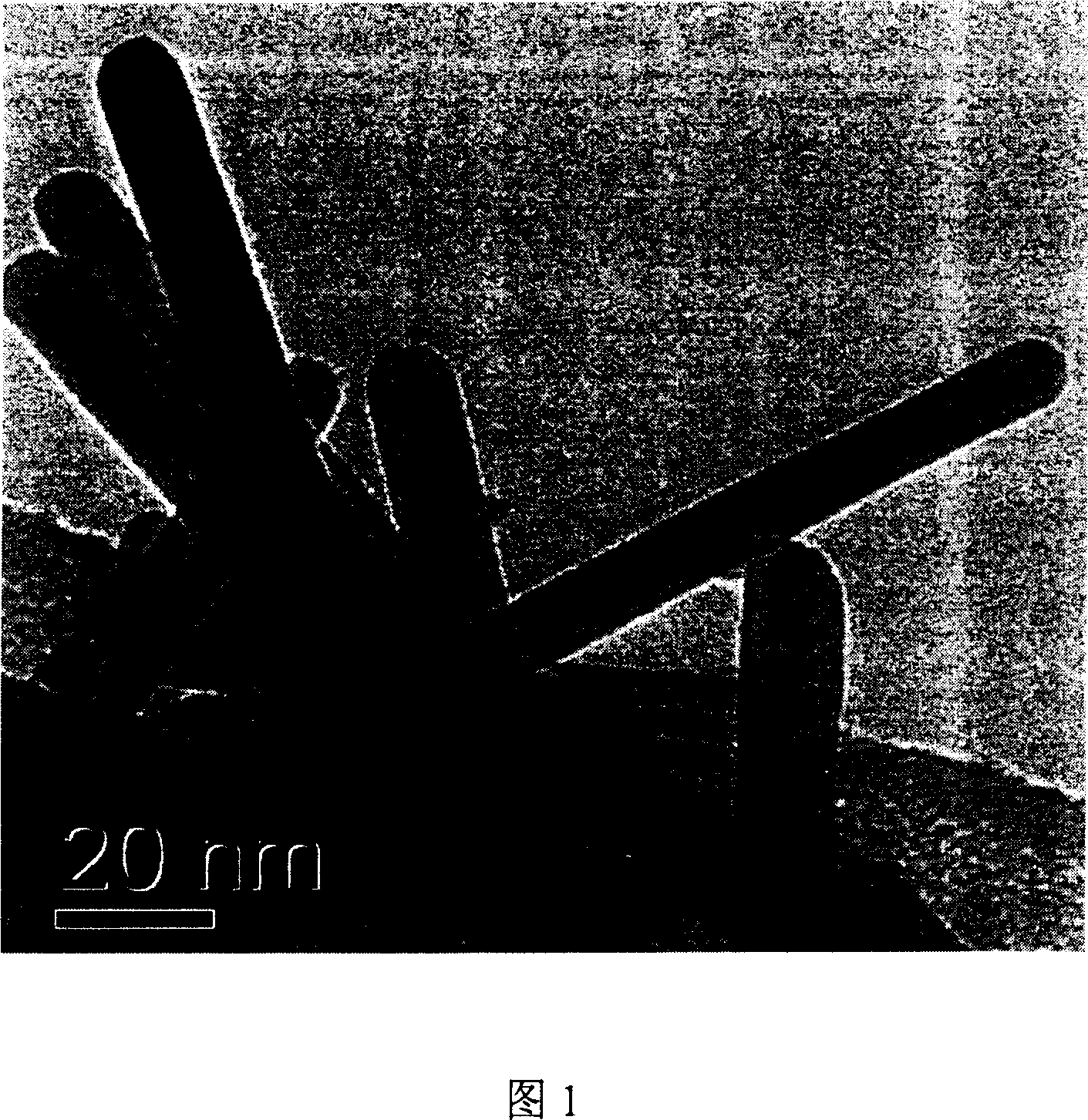

[0012] Example 1: 2.0206g (50mmol) of analytically pure sodium hydroxide was dissolved in 50mL of absolute ethanol under magnetic stirring. Disperse 0.2855 g (1.1 mmol) of analytically pure cobalt acetate with 4 crystal waters and 2.2141 g (10 mmol) of analytically pure zinc acetate with 2 crystal waters in 100 mL of absolute ethanol under magnetic stirring. After the zinc acetate is completely dissolved, add the sodium hydroxide solution to the ethanol dispersion of cobalt acetate and zinc acetate under magnetic stirring, transfer the resulting mixture into a reaction kettle, seal it, and transfer it to an oven at 120°C for heat preservation 2 hours. After the reaction, the reactor was taken out and cooled to room temperature naturally. Finally, the product (light green) was separated by filtration, washed repeatedly with water, and then dried naturally in the air to obtain light green Zn 1-x co x O nanorods.

example 2

[0013] Example 2: 2.0174g (50mmol) of analytically pure sodium hydroxide was dissolved in 50mL of absolute ethanol under magnetic stirring. With 0.2196g (0.88mmol) analytically pure cobalt acetate with 4 crystal waters and 2.2018g (10mmol) analytically pure zinc acetate with 2 crystal waters and 0.0189g (0.11mmol) analytically pure silver nitrate in magnetic stirring Disperse in 100 mL of absolute ethanol. After the zinc acetate and silver nitrate dissolve completely, add the sodium hydroxide solution to the ethanol dispersion of cobalt acetate, silver nitrate and zinc acetate under magnetic stirring, transfer the obtained mixture into the reaction kettle, seal it, and transfer it to the In an oven at 120°C, keep warm for 2 hours. After the reaction, the reactor was taken out and cooled to room temperature naturally. Finally, the product was separated by filtration, washed repeatedly with water, and then dried naturally in the air to obtain Zn 1-x co x O: Ag nanorods dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com