Low temperature prepn process of biological thiosulfate radical ion and hydrogen sulfide removing agent

A technology of thiosulfate and hydrogen sulfide, applied to methods using microorganisms, chemical instruments and methods, sustainable biological treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

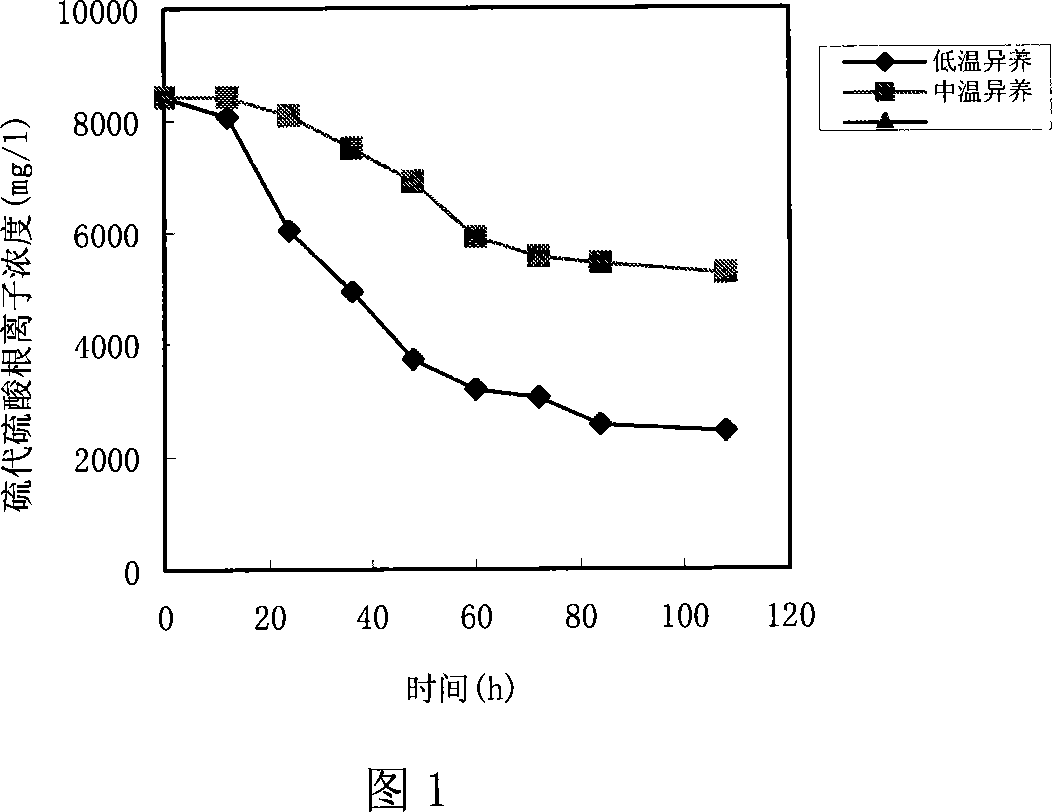

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific embodiment 1: In this embodiment, the preparation method of the biological remover of thiosulfate ion and hydrogen sulfide at low temperature is realized by the following steps: 1. Domestication: In February, the activated sludge of the sewage treatment plant is taken as the source of bacteria. Under the condition of an ambient temperature of 3~8℃, the activated sludge is inoculated into a biological trickling filter tower with activated carbon as the filler, and the concentration of 40~60mg / m is first introduced into the biological trickling filter tower. 3 H 2 S gas, then increase H within 30 to 90 days 2 S gas inlet concentration to 300~500mg / m 3 , And then start using H 2 The S detection tube detects the outgassing effect. When the outgassing effect remains stable, the domestication stage is completed; 2. Low-temperature bacteria screening: Take 3~5g of the domesticated filler inoculated with activated sludge, and take 100~110ml of sterile water for inoculation...

specific Embodiment approach 2

[0006] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the activated sludge is inoculated into a biological trickling filter tower with activated carbon as a filler under the condition of an ambient temperature of 4 to 6°C. The other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, the activated sludge is inoculated into a biological trickling filter tower with activated carbon as a filler under the condition of an ambient temperature of 5°C. The other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com