Process for extracting capsaicin crystal from dry capsium

A process method and capsaicin technology are applied in the technical field of extracting capsaicin crystals from dried capsicum, which can solve the problems of high refining difficulty and high impurity content of capsicum essence, and achieve the effects of simple process, easy refining and purification, and easy operation and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of extractant modified ethanol solution

[0034] Dissolve 4kgNaCl in water and dilute to 100kg to obtain 4% NaCl aqueous solution; weigh 5kgNaHCO 3 Dissolve in water and dilute to 100kg to get 5% NaHCO 3 Aqueous solution: Weigh 1kg NaOH, dissolve it in water and dilute to 100kg to obtain 1% NaOH aqueous solution.

[0035] Mix 100kg of 4% NaCl aqueous solution, 60kg of 5% NaHCO3 aqueous solution and 40kg of 1% NaOH aqueous solution in a dissolving tank, and then gradually add 300kg of 95% edible ethanol under stirring, stirring and dissolving for 10min to 20min, and obtain the modified extractant weak.

Embodiment 2

[0036] Embodiment 2: the preparation of preparation

[0037] Weigh sodium acetate (CH 3 COONa·3H 2 (2) 8kg is dissolved in water and diluted to 100kg to obtain 8% sodium acetate solution; NaCl 10kg is dissolved in water and diluted to 100kg to obtain 10% NaCl solution; 4.3kg of 35% concentrated hydrochloric acid is diluted to 100kg with water 100kg to obtain 1.5% hydrochloric acid aqueous solution.

[0038] In the dissolving tank, under stirring, add 100kg 8% NaCl solution, 50kg 10% NaCl solution and 20kg 1.5% hydrochloric acid aqueous solution, add water to dilute to 1000kg after mixing, and obtain the preparation after mixing.

Embodiment 3

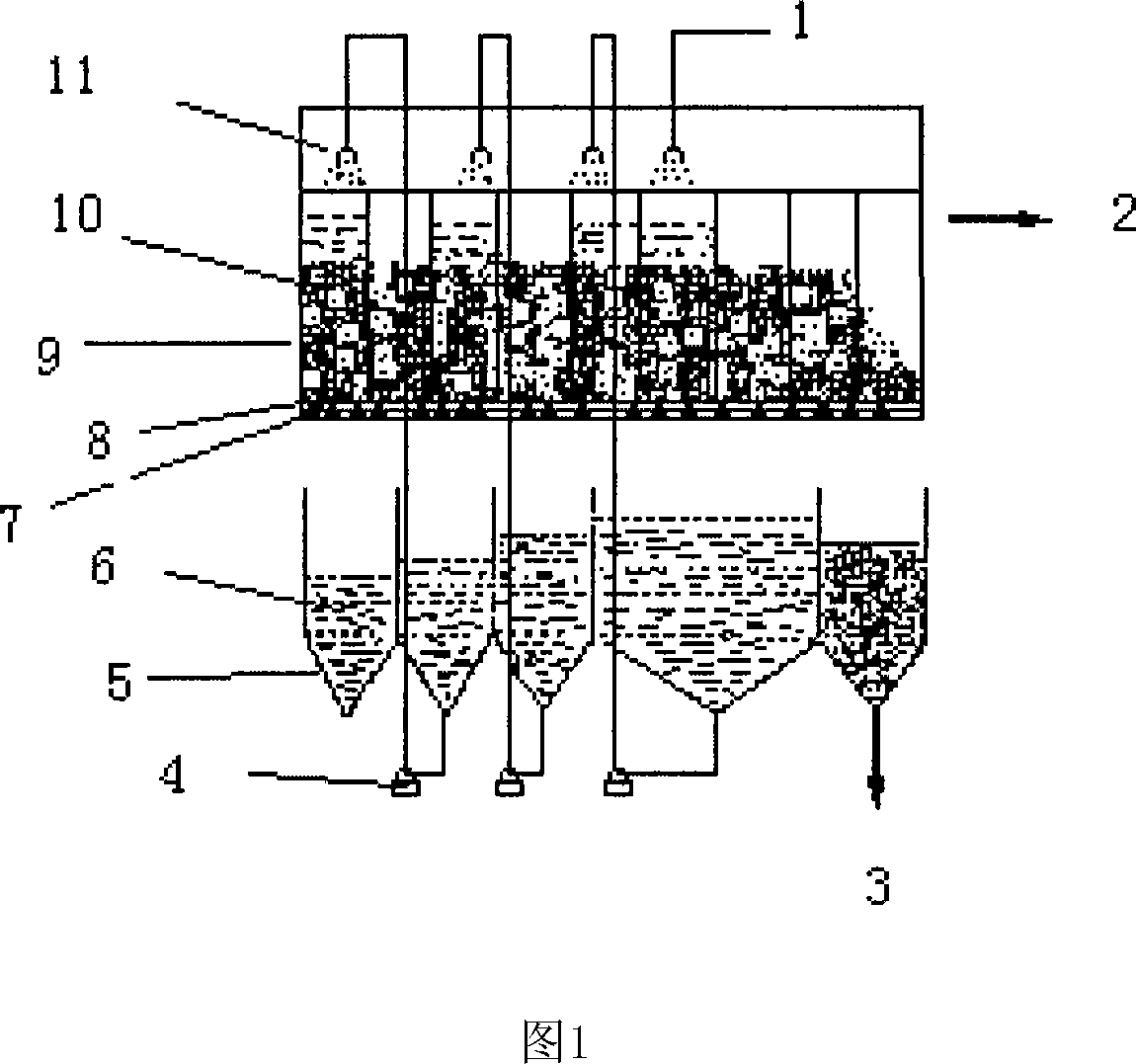

[0040]Add 250kg chili sticks (the chili sticks are made by crushing and granulating dried chili peppers after deseeding) to each material grain (totally 16 material grains) in the extractor, adjust the speed of the leaching outlet to 180min / r (180 minutes per revolution) ), preheat 500kg of extractant to 45°C±2°C in the preheater, then spray and leaching the chili stick layer in the feed tank, drip into the receiver through the screen at the bottom of the feed tank, and then pump it out, pass through The spray pipe sprays to the chili stick layer in the transferred material tank. According to this operation, the extractant goes through the process of "spray-drip dry-spray-drip dry", and the concentration gradually increases to form a gradient extraction, and finally obtain an appropriate concentration of leachate.

[0041] In the above leaching process, the raw materials of the new chili sticks are sprayed with a concentrated extractant, and the pepper sticks sprayed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com