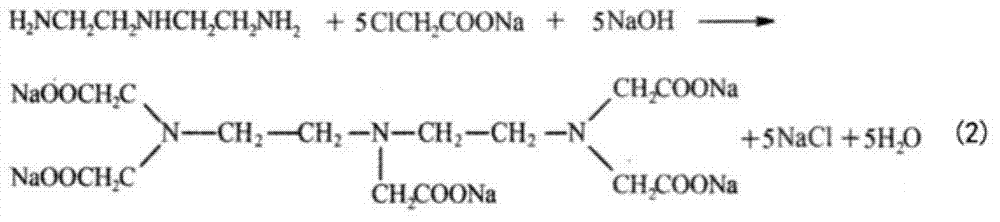

Synthesis method of DTPA (diethylene triamine pentacetic acid) penta-sodium salt

A synthesis method and sodium salt technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of affecting the yield of DTPA, intensified hydrolysis of sodium chloroacetate, and inability to compete with similar products, and achieve a beneficial effect. The effect of later refining and purification, stable reaction and shortening of process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

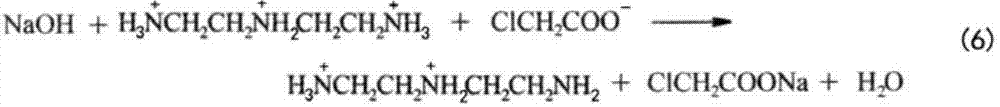

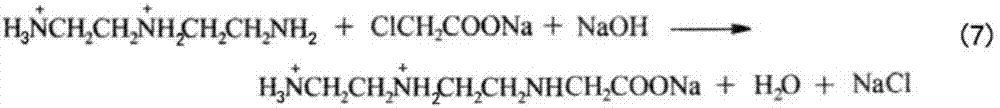

Method used

Image

Examples

Embodiment 1

[0064] Dissolve 240 kg of chloroacetic acid in 80 kg of deionized water to prepare a chloroacetic acid solution; slowly add 52 kg of diethylenetriamine, turn on the cooling device, and put ice water into the jacket to control the temperature of the reaction system at -10 to -5°C; Then slowly add 630 kg of 32-33% sodium hydroxide solution in two batches. When the first 315 kg is slowly added, the jacket is fed with ice water to control the reaction temperature at -10~-5°C; the last 315 kg of sodium hydroxide When the solution is slowly added, the temperature of the reaction system is controlled by feeding water into the jacket to be 55-60° C. After the sodium hydroxide solution is added, the temperature is kept for 3 hours; the pH value of the solution is adjusted to 11.5, and the temperature is lowered to room temperature, and the material is filtered out.

Embodiment 2

[0066] Dissolve 240 kg of chloroacetic acid in 80 kg of deionized water to prepare a chloroacetic acid solution; slowly add 52 kg of diethylenetriamine, open the cooling device, and put ice water into the jacket to control the temperature of the reaction system to be -5 to 0°C; then Slowly add 630 kg of 32-33% sodium hydroxide solution in two batches. When the first 315 kg is slowly added, the jacket is fed with ice water to control the reaction temperature at -5~0°C; the last 315 kg of sodium hydroxide solution is slowly added. When adding, the temperature of the reaction system is controlled by feeding water into the jacket to be 45-50° C. After adding the sodium hydroxide solution, it is kept warm for 4 hours; the pH value of the solution is adjusted to 11.5, cooled to room temperature, and filtered out.

Embodiment 3

[0068] Dissolve 240 kg of chloroacetic acid in 80 kg of deionized water to prepare a chloroacetic acid solution; slowly add 52 kg of diethylenetriamine, open the cooling device, and put ice water into the jacket to control the temperature of the reaction system to be 0-5°C; Slowly add 630 kg of 32-33% sodium hydroxide solution in 2 batches. When the first 315 kg is slowly added, the jacket is filled with ice water to control the reaction temperature at 0-5°C; when the last 315 kg of sodium hydroxide solution is slowly added , the temperature of the reaction system is controlled by feeding water into the jacket to be 50-55° C., and the sodium hydroxide solution is added and kept warm for 5 hours; the pH value of the solution is adjusted to 11.5, and the temperature is lowered to room temperature, and the material is filtered and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com