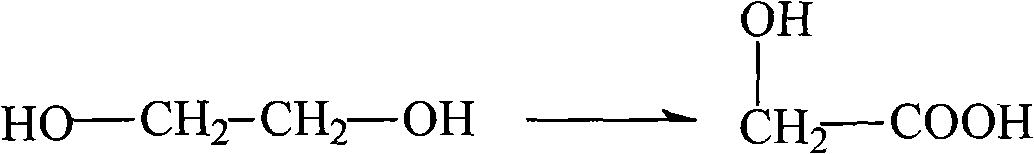

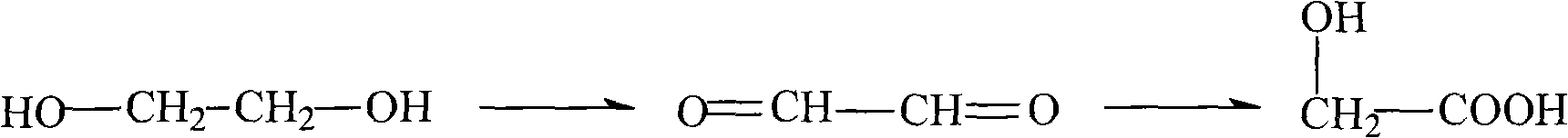

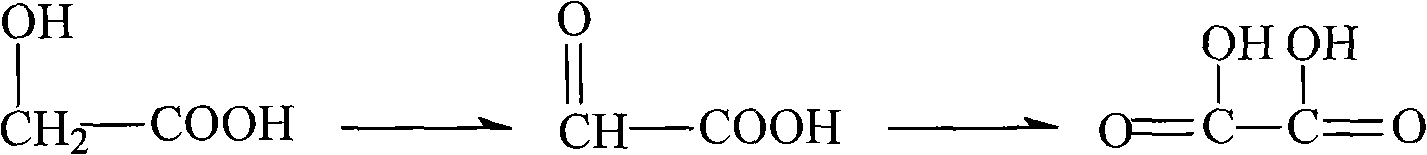

Method for preparing glycollic acid by glycol

A technology of glycolic acid and ethylene glycol is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high production cost, long process flow, unsatisfactory reaction yield, etc., and achieves production cost Reduced, ideal selectivity, easy to refine and purify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0024] Drop into 300 grams of ethylene glycol aqueous solution in the 500 milliliter reactor with stirring, replace the air in the reactor with nitrogen three times, add the required amount of catalyst V 2 o 5 and Al 2 o 3 . Heating the reactants to gradually increase the temperature. During the heating process, oxygen is introduced into the reactor and the set reaction pressure is maintained. After the reactants reach the set reaction temperature, the oxygen is stopped. The set reaction temperature is maintained until the set reaction time is reached, the reaction is completed and the material is cooled and discharged to obtain a brownish-yellow liquid. The specific reaction conditions of each embodiment are shown in Table 1, wherein the consumption of catalyst is based on ethylene glycol.

[0025] The composition of the reaction product was analyzed by gas chromatography, and the conversion rate of ethylene glycol, the selectivity of glycolic acid and the yield of glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com