Cis-based thin film solar battery and process for producing the same

A technology for solar cells and thin films, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problem of no report teaching the necessity of an alkali barrier layer, etc., and achieve the effect of improving productivity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Embodiments of the present invention will be described below

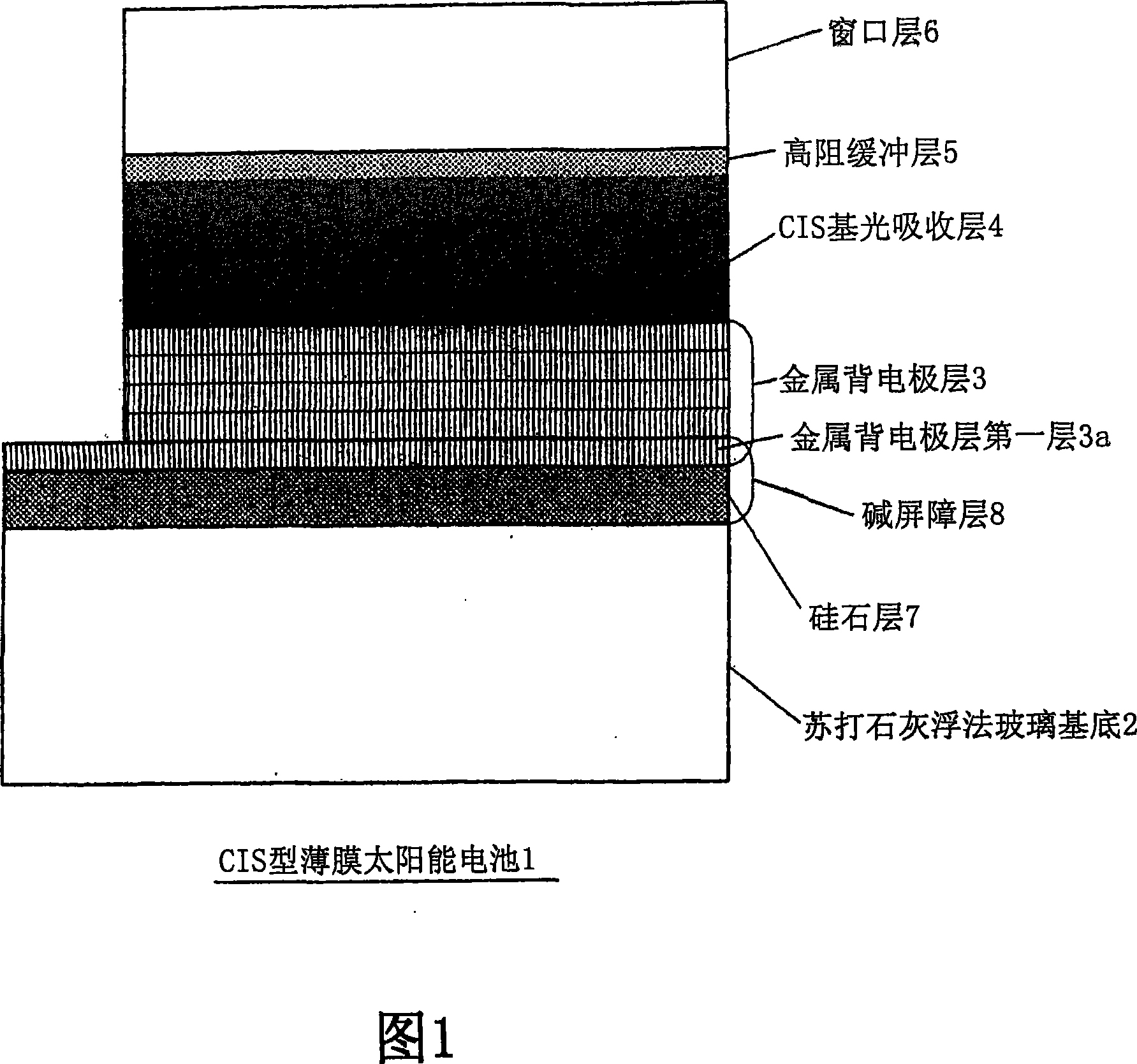

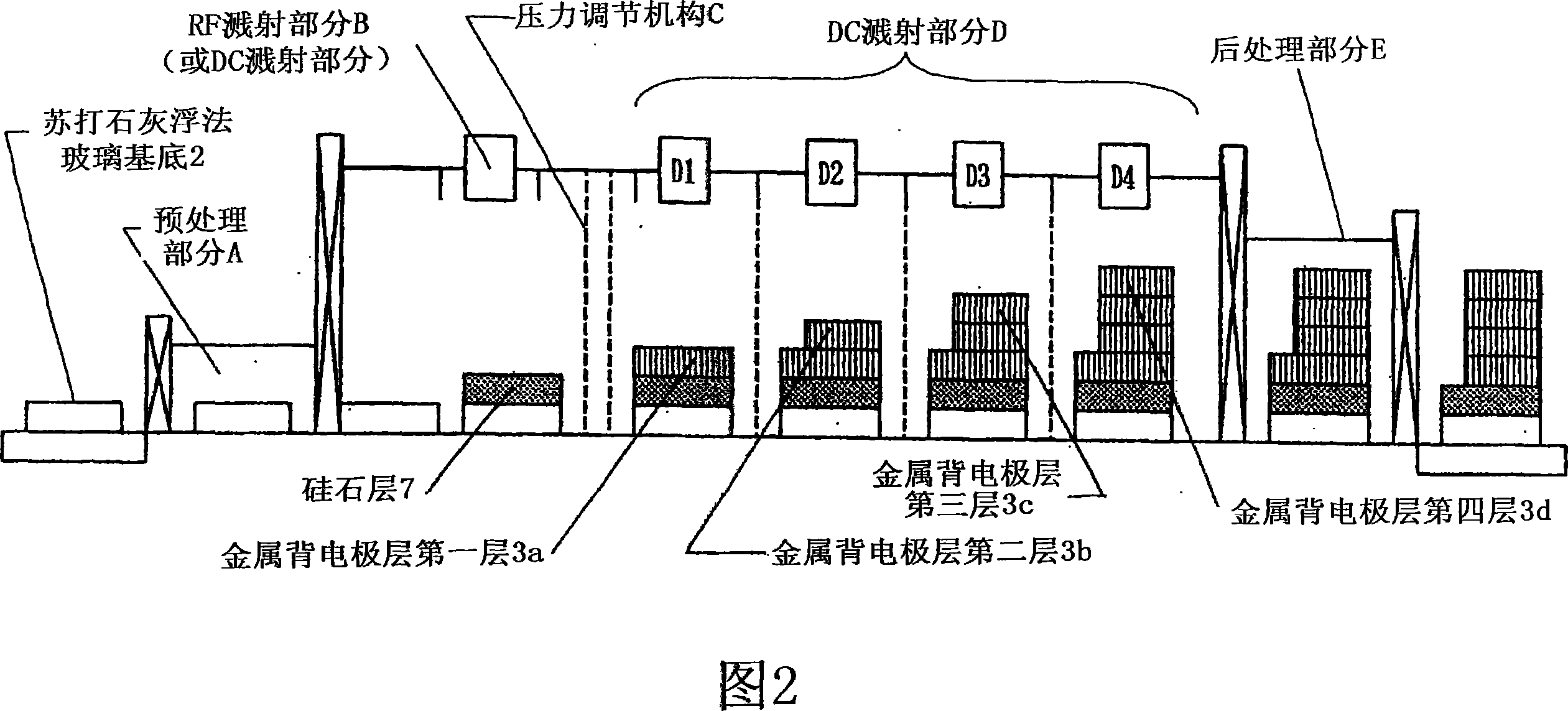

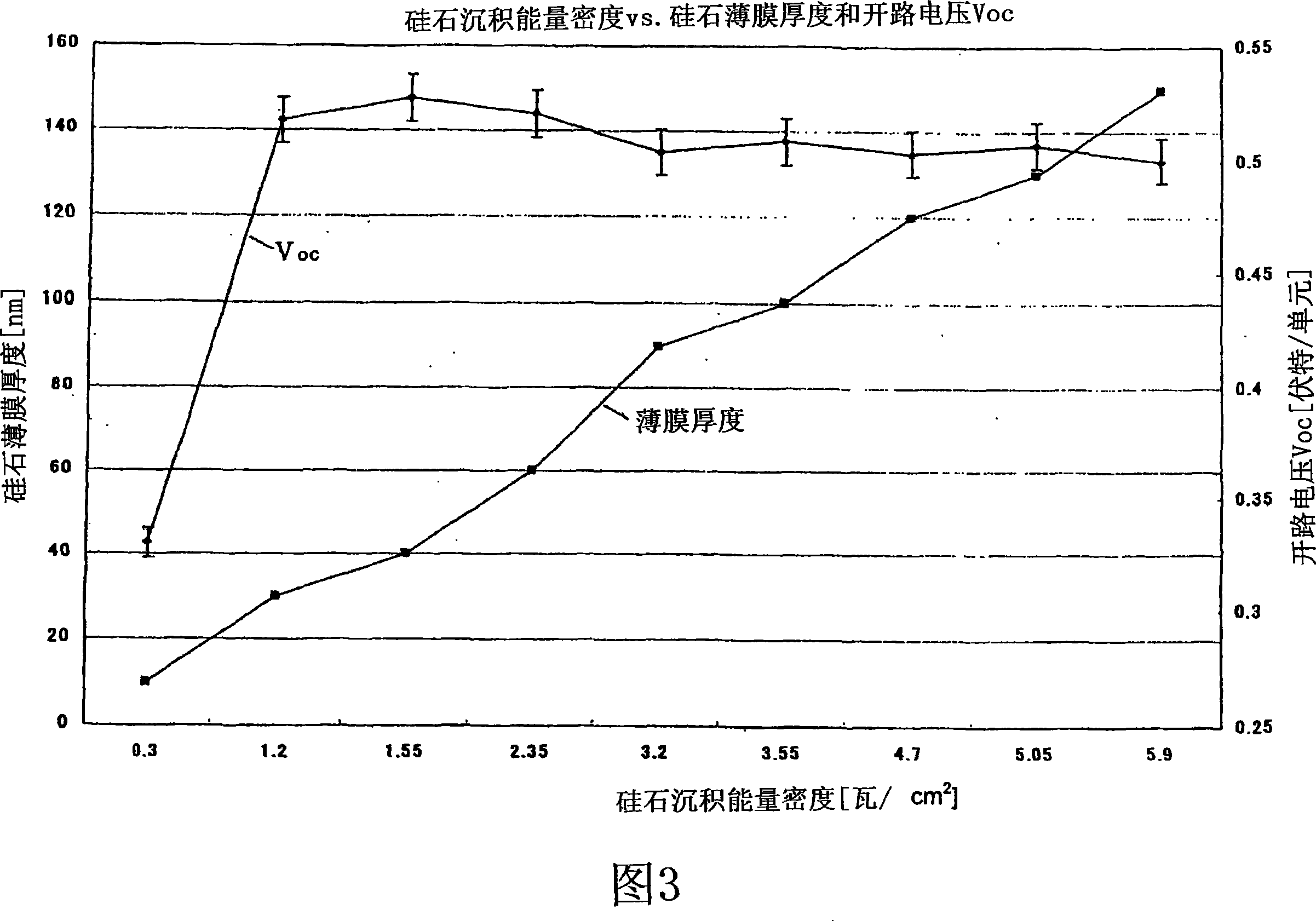

[0079] The present invention relates to a method of forming an alkali barrier layer 8 for preventing and controlling alkali formation when a light absorbing layer is deposited on a metal back electrode layer 3 deposited on a soda lime float glass substrate 2 heat diffusion from the soda lime float glass substrate 2 into the light absorbing layer 4 comprising a P-type semiconductor. Furthermore, the invention relates to a CIS-type thin-film solar cell 1 with an alkali barrier layer 8 .

[0080] The alkali barrier layer 8 may be a first alkali barrier layer which is a silica layer 7 formed on a soda lime float glass substrate, or the alkali barrier layer 8 may be a second alkali barrier layer which is The di-alkali barrier layer is a multilayer alkali barrier layer consisting of a silica layer 7 and a first layer 3a of the multilayer metal back electrode layer directly above the silica layer 7 .

[0081] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com