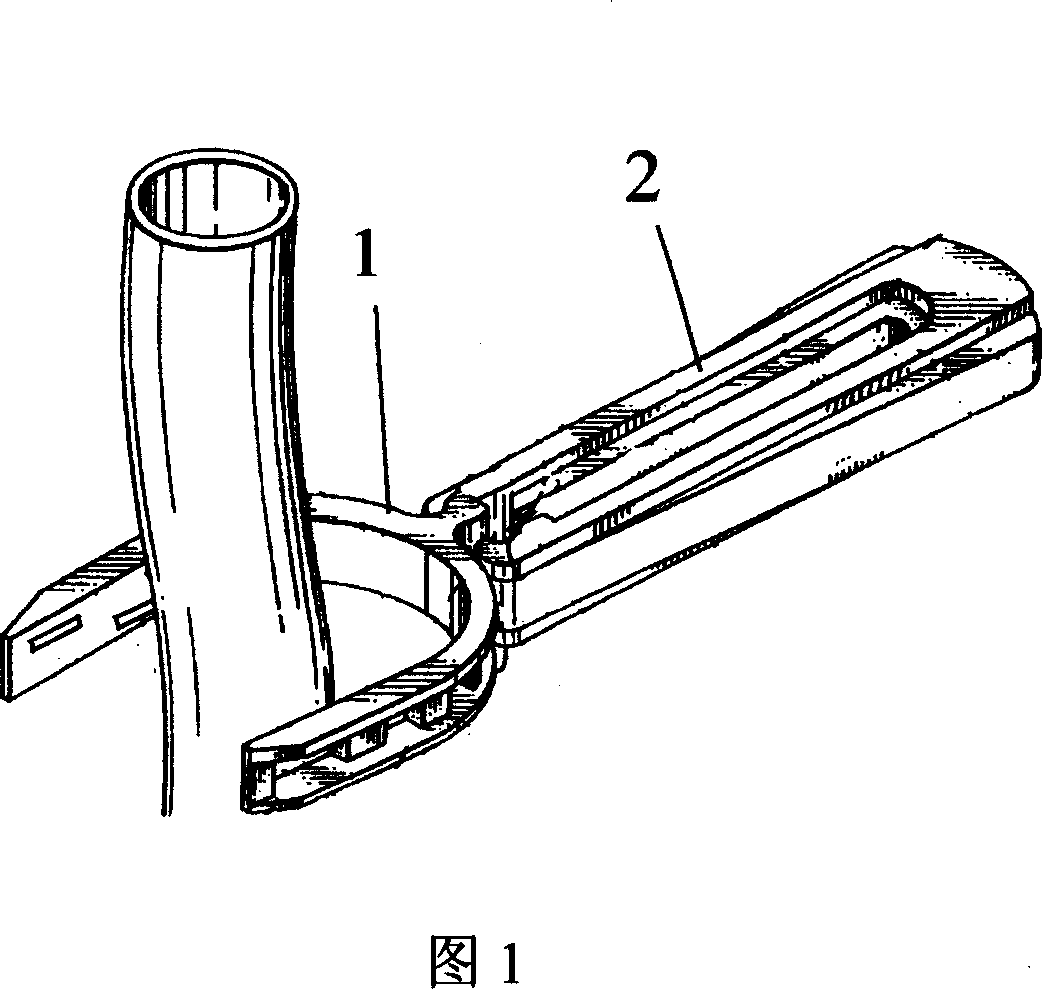

Adsorbable hemostatic ligation clip

A ligation clip and lactide technology, applied in wound clips, medical science, surgery, etc., can solve the problems of insufficient softness, damage, poor hydrophilicity, etc., and achieve soft materials, increased hydrophilicity, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of polydioxanone material:

[0025] Put 200 grams of polymer-grade p-dioxanone in the reactor, add 0.01% stannous octoate catalyst, react under vacuum conditions at 140°C for 6 hours, and add the reactant to the extruder at 140°C to obtain a diameter Particles of 1-2 mm and 5-10 mm in length of polydioxanone, the above pellets were vacuum dried at 50° C. for 24 hours and weighed 187 grams, with a yield of 93.5%. Using phenol / 1,1,2,2-tetrachloroethane (2:3 / W:W) mixed solution as solvent, using Ubbelohde viscometer in a constant temperature water bath at 25 ℃, measured polydioxanone The intrinsic viscosity of 2.78dl / g.

[0026] Preparation of Polyglycolide:

[0027] The polymer grade glycolide was placed in the reactor, stannous octoate catalyst was added, and the reaction was carried out under vacuum conditions at 240°C for an appropriate time. 10 mm pellets of polyglycolide, the above pellets were vacuum dried at 50°C for 24 hours. The melt index of poly...

Embodiment 2

[0030] Preparation of polydioxanone material:

[0031] Put 200 grams of polymer-grade p-dioxanone in the reactor, add 0.02% stannous octoate catalyst, and react under vacuum conditions at 140 ° C for 10 hours. Add the reactant to the extruder at 140 ° C to obtain a diameter Granules of 1-2 mm and 5-10 mm in length of polydioxanone, the above pellets were vacuum-dried at 50° C. for 24 hours and weighed 196 grams, with a yield of 98%. Using phenol / 1,1,2,2-tetrachloroethane (2:3 / W:W) mixed solution as solvent, using Ubbelohde viscometer in a constant temperature water bath at 25 ℃, measured polydioxanone The intrinsic viscosity of 4.78dl / g.

[0032] Processing of the absorbable hemostatic ligation clip: The above-synthesized polydioxanone is processed into an inner layer card by an injection molding method, the temperature is 175-180° C., and the tensile strength of the inner layer is 78Mpa after testing.

Embodiment 3

[0034] Preparation of polydioxanone material:

[0035] Put 200 grams of polymer grade p-dioxanone in the reactor, add 0.01% stannous octoate catalyst, react under vacuum conditions at 140 ° C for 10 hours, and add the reactant to the extruder at 140 ° C to obtain a diameter Granules of 1-2 mm and 5-10 mm long polydioxanone, the above pellets were vacuum-dried at 50° C. for 24 hours and weighed 190 g, the yield was 95%. Using phenol / 1,1,2,2-tetrachloroethane (2:3 / W:W) mixed solution as solvent, using Ubbelohde viscometer in a constant temperature water bath at 25 ℃, measured polydioxanone The intrinsic viscosity of 3.29dl / g.

[0036] Processing of the absorbable hemostatic ligation clip: The above-synthesized polydioxanone is processed into an inner layer card by an injection molding method, the temperature is 170-175° C., and the tensile strength of the inner layer is 70 MPa after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com