Semiconductor light-emitting device and method for separating semiconductor light-emitting devices

A light-emitting device and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of increasing the manufacturing cost of light-emitting devices, achieve the effect of shortening the processing time and increasing the production volume of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

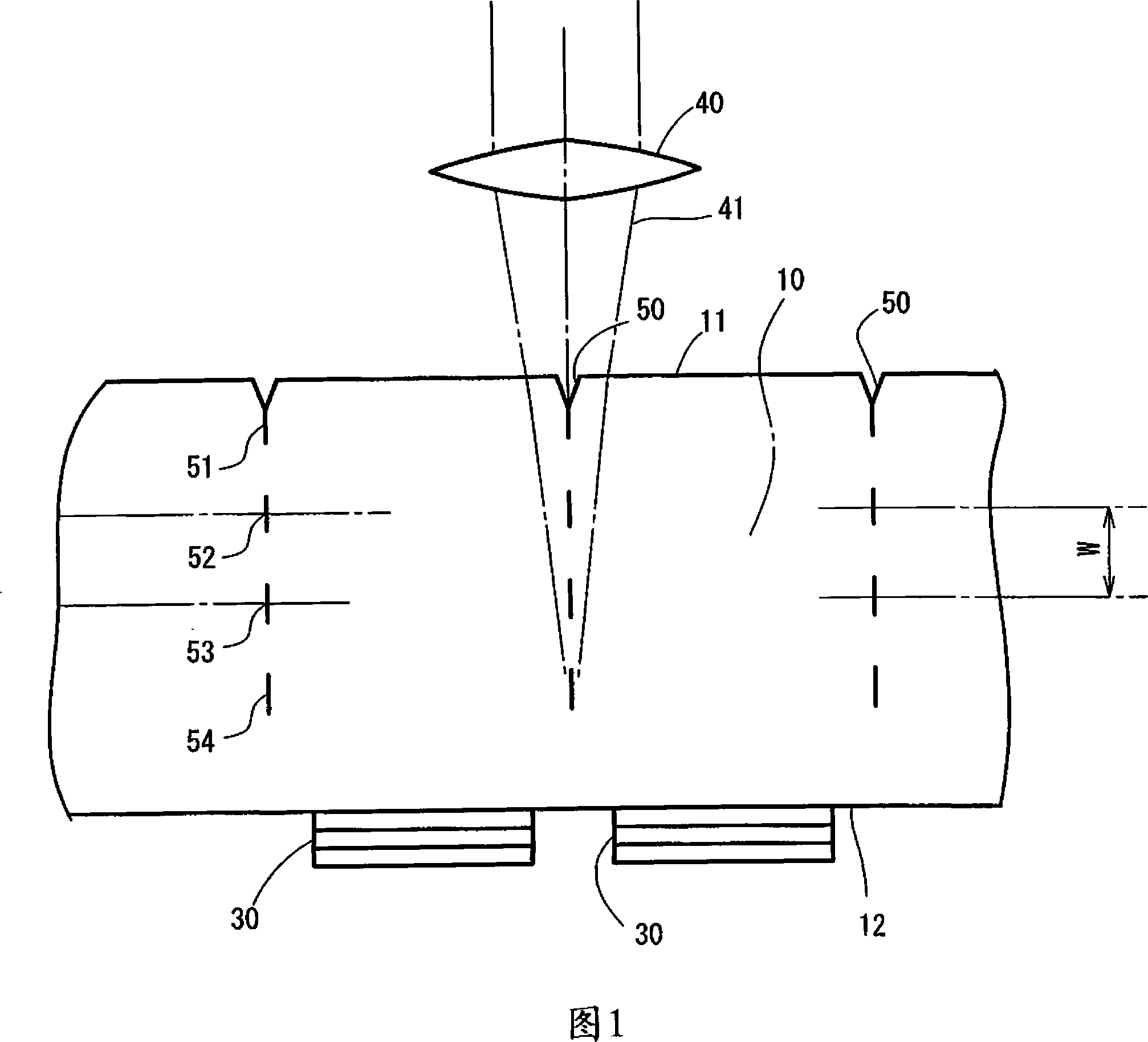

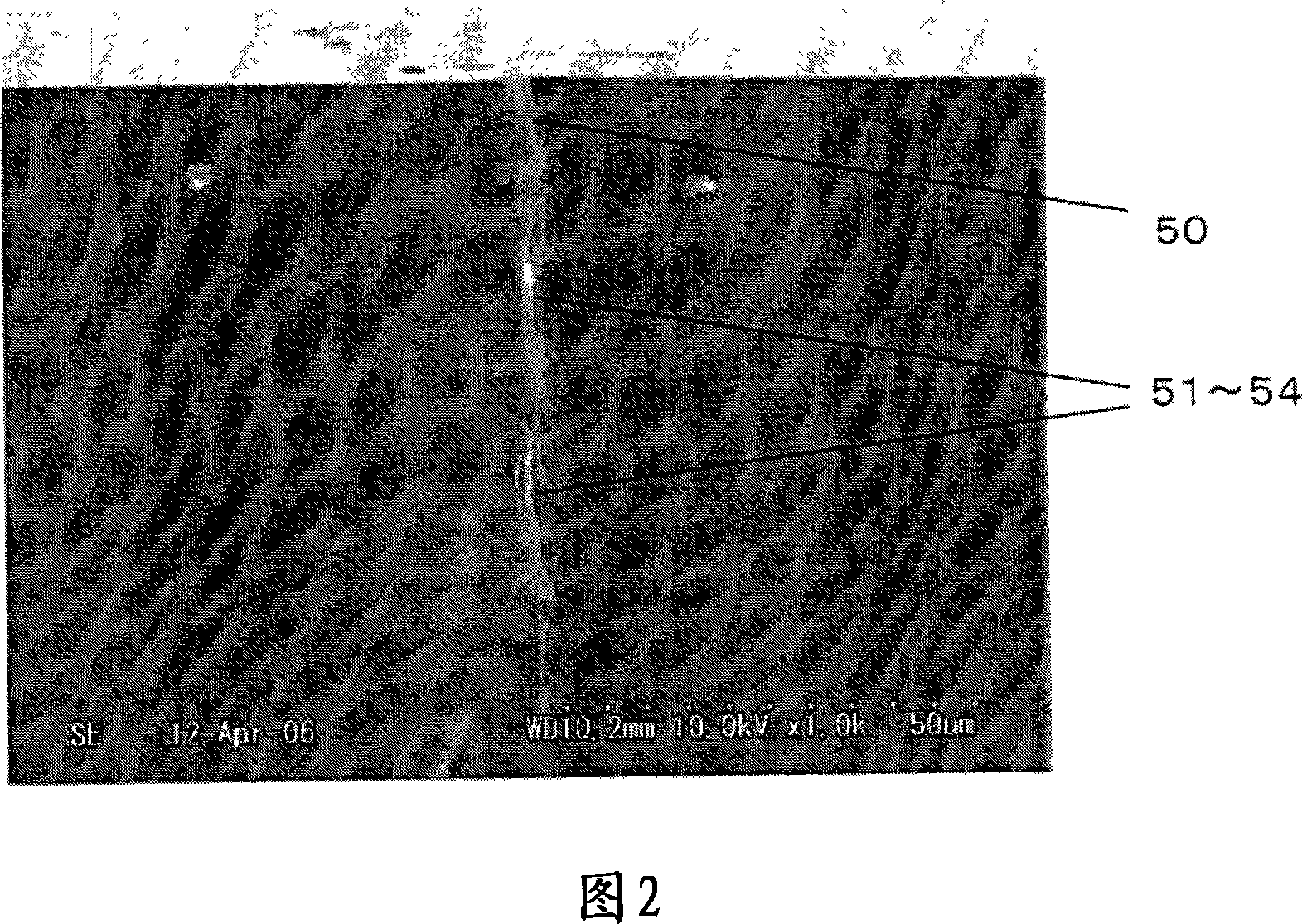

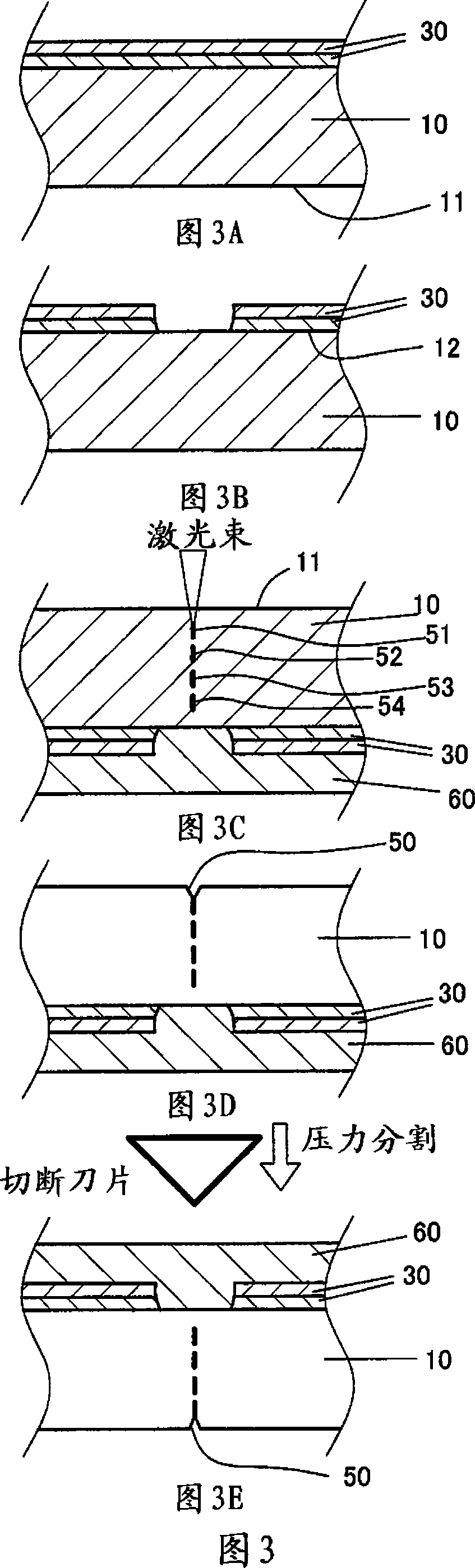

[0091] 3A to 3E illustrate steps included in a method for separating semiconductor light emitting devices according to a specific example of the present invention. As shown in FIG. 3A , a semiconductor light emitting device 30 based on a group III nitride compound was formed on one surface 12 of a sapphire substrate 10 having a thickness of 140 μm through epitaxial growth, electrode formation, and other steps. Subsequently, portions near the division lines unnecessary for separating the group III nitride compound-based semiconductor light emitting device 30 are removed by etching (FIG. 3B).

[0092] Next, an adhesive tape (adhesive tape) 60 is attached to the surface of the sapphire substrate 10 on which the semiconductor light emitting device 30 based on the group III nitride compound is formed, and the femtosecond pulsed laser beam is placed on the surface as the back surface of the sapphire substrate 10 11, thereby forming the groove 50 and the structurally modified portion...

Embodiment 2

[0101] Example 2 relates to a method for separating light-emitting diode chips according to the invention. Figure 7 shows a configuration of an LED in which a light emitting diode chip is mounted on a support and processed according to one embodiment of the present invention. It is worth noting that Figure 7 is a schematic view, and the lateral / vertical dimensions and layer thicknesses do not reflect actual values. Actually, the transparent substrate 101 has a thickness on the order of about 100 μm, and the semiconductor layer 102 which is a stacked layer including a light emitting layer has a thickness of about 1 μm. The LED chip 103 includes a transparent substrate 101 and a semiconductor layer 102 . The adopted transparent substrate 101 is made of sapphire. The semiconductor layer 102 which is a stacked nitride semiconductor layer including a light emitting layer is formed on the first surface 111 ′ of the sapphire substrate 101 , while the second surface 111 of the trans...

example 2

[0156] As shown in Figure 16, internal embrittlement steps 1 to 19 are performed sequentially. Then, steps 20 and 21 are performed to form the grooves. The process is carried out under the following conditions:

[0157] Workpiece: Sapphire single crystal (thickness: t=500μm)

[0158] Laser equipment: mode-locked fiber laser-based femtosecond laser equipment doped with Er and Yb at the same time

[0159] Wavelength: 1.045μm

[0160] Pulse width: 400fs

[0161] Pulse repetition frequency: 100kHz

[0162] Condenser lens: numerical aperture 0.65, and focal length 4mm

[0163] Pulse energy after condenser lens: 1.5μJ

[0164] Energy flow at the waist: 160J / cm 2 (Calculated)

[0165] Power density at the waist: 400TW / cm 2 (Calculated)

[0166] Laser beam incident surface: c-plane of sapphire crystal (second surface 111 in FIG. 16 )

[0167] Laser beam incident direction: orthogonal to the C-plane (the direction indicated by the white arrow in Figure 16)

[0168] Number o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com